Why Hygiene Is Critical in Beverage Production

The beverage industry churns out around 1,000 bottles every six seconds worldwide according to Beverage Industry Report data from last year. These production lines move at breakneck speed, but soft drink filling machines remain the last defense against microbes getting into drinks before they hit store shelves. When something goes wrong with these machines, companies face massive problems. Batch recalls typically cost around 740 thousand dollars on average as per Ponemon's research from 2023. The sweet stuff flowing through these systems actually creates perfect breeding grounds for bacteria. That's why strict cleaning routines are so important for keeping dangerous germs like E. coli and Salmonella from hiding in hard to reach spots inside the equipment or along transfer lines where they could contaminate entire batches.

How Machine Hygiene Directly Impacts Product Safety

Filling nozzles and conveyor belts account for 63% of contamination incidents in bottling plants (Food Safety Magazine 2022). When residues accumulate in these components:

- Microorganisms proliferate at rates exceeding 1,000 CFU/cm² within 8 hours

- pH-sensitive products like citrus-based drinks corrode unprotected metal surfaces

- Particulate matter alters carbonation levels, affecting flavor consistency

Automated rinsing cycles and food-grade lubricants reduce these risks by 89% compared to manual cleaning alone.

Food Safety Regulations and Compliance for Soft Drink Filling Machines

The FDA's Current Good Manufacturing Practices (CGMP) mandate:

| Requirement | Frequency | Verification Method |

|---|---|---|

| Surface microbial testing | Every 8 hours | ATP bioluminescence swabs |

| Material compatibility | At installation | NSF/ISO 21488 certification |

| Seal integrity checks | Daily | Pressure decay analysis |

Non-compliance penalties now exceed $450k per violation under FSMA's Sanitary Transportation Rule (2024 update).

Common Contamination Sources in Soft Drink Filling Processes

- Biofilm formation: Persistent microbial colonies in hard-to-clean areas like valve diaphragms

- Airborne particulates: Dust and microbes entering through unsealed packaging interfaces

- Lubricant migration: NSF H1-grade lubricants degrading into product zones after 300+ operating hours

- Residual sugars: Crystallized deposits attracting Aspergillus molds within 72 hours

Proactive hygiene management reduces these risks by 92% while extending equipment lifespan by 40% (Journal of Food Engineering 2023).

Effective Cleaning and Sanitization of Soft Drink Filling Machines

Clean-in-place (CIP) systems and their role in hygiene maintenance

CIP systems these days make cleaning possible without taking apart those soft drink filling machines, which cuts down on contamination problems quite a bit. Actually, they reduce contamination by around 74% less than when people do it manually according to Food Safety Magazine from last year. The closed loop approach sends detergents and sanitizers through the system at just the right temps, getting rid of those stubborn biofilms that tend to form in all sorts of places like valves and along pipeline walls. Some newer models come equipped with conductivity sensors that check the strength of cleaning solutions as they work, so operators know for sure that sticky sugar residue and those pesky acid deposits get cleaned out properly during each run in beverage manufacturing plants.

Food-grade sanitizers and cleaning agents: efficacy and safety

Peracetic acid and nitric acid mixtures can knock down microbes by nearly 99.99%, which is pretty impressive when we look at FDA regulations under 21 CFR §178.1010 for surfaces that touch food products. When it comes to cleaning, alkaline solutions work best around 65 to 80 degrees Celsius (about 149 to 176 Fahrenheit) to break down those stubborn organic leftovers. Acid rinses, on the other hand, help keep scale from building up inside carbonated beverage lines, something manufacturers really need to worry about. Independent research has actually demonstrated that enzyme-based cleaners cut down on water consumption by roughly 30% over regular chemical alternatives. These eco-friendly options still get the job done in terms of cleanliness but won't eat away at stainless steel parts like some harsher formulas might do.

Nozzle hygiene and prevention of microbial buildup

The filling nozzles need extra care because they touch the product directly and have areas where liquid just sits around. Most plants do daily high-pressure rinses using hot water around 85 degrees Celsius or 185 Fahrenheit to knock back those pesky Streptococcus and Lactobacillus bugs. Once a week, we take them apart completely so someone can get into all the little cracks with brushes. A few companies have started applying special coatings with silver ions on their equipment surfaces. According to some research published last year in the Journal of Food Protection, this actually cuts down contamination problems by about half during fast paced bottling runs. Now there are these automated inspection systems that use UV-C lighting technology which spots early signs of biofilm buildup long before bacteria levels reach dangerous amounts measured in colony forming units per square centimeter.

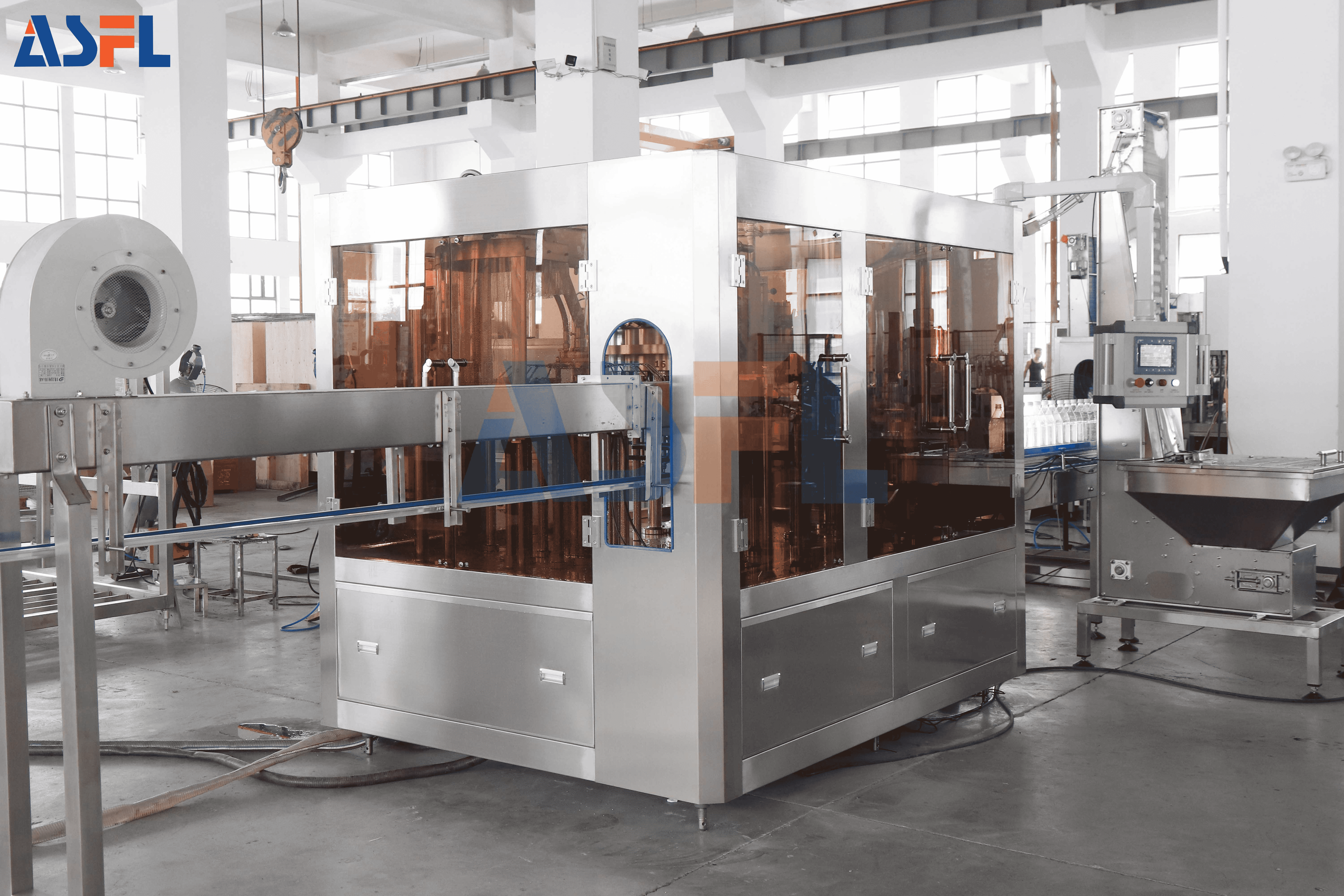

Design and Automation Features That Prevent Contamination

Modern soft drink filling machines integrate advanced engineering to eliminate contamination risks while meeting strict food safety standards. Three key design strategies ensure hygienic operation across production cycles.

Hygienic Design Principles: Smooth Surfaces, Minimal Crevices, and Cleanability

Equipment featuring smooth, crevice-free surfaces cuts down on biofilm buildup by about 89% when compared against textured counterparts according to recent studies from NSF/3-A in 2024. The electropolished stainless steel variant has become the go-to material for important parts such as filler nozzles and areas where products actually touch during processing because it creates a surface so fine at the microscopic level. What makes this finish special is how it stops particles from sticking around and allows those automated cleaning systems known as CIP (Clean-in-Place) to wipe away roughly 99.7 percent of organic stuff left behind after regular washing procedures. Most manufacturers these days stick to rounded corners and maintain surface roughness below 10 micrometers as standard practice if they want their equipment to stay truly cleanable over time.

Sealed Environments and Automated Handling to Reduce Human Contact

Enclosed filling chambers equipped with advanced air filtration systems that meet ISO Class 5 standards keep dust and other airborne particles out of the product stream during processing. Most modern production lines now rely heavily on robotic arms for container handling tasks, with these machines taking care of about 90-95% of the movement work and significantly reducing direct human interaction in sterile areas. For rotary joints, manufacturers install double mechanical seals which create necessary pressure barriers against outside contaminants. This design has shown remarkable results in juice processing facilities according to recent FDA field reports from 2023, cutting down yeast and mold issues by roughly three-quarters compared to older equipment setups.

Material Selection: Corrosion-Resistant, Non-Porous Components for Safety

| Material Property | Food Safety Impact | Common Applications |

|---|---|---|

| 316L Stainless Steel | Resists acidic cleaners/pH swings | Filler valves, product tanks |

| FDA-Grade Silicone | Withstands 150°C sanitization | Gaskets, diaphragm seals |

| PEEK Thermoplastic | Eliminates metal ion migration | Conveyor guides, sensor housings |

Non-reactive polymers and passivated metals prevent chemical leaching, addressing 58% of flavor-altering contamination cases in carbonated beverages (EFSA 2022). All materials undergo third-party verification for USP Class VI biocompatibility and NSF/3-A certification.

Monitoring, Maintenance, and Continuous Hygiene Assurance

Scheduled Cleaning and Preventive Maintenance Routines

Studies from the Ponemon Institute back in 2023 found that when companies stick to proactive maintenance routines instead of waiting for problems, they cut down contamination risks in their soft drink filling machines by around 72%. For everyday operations, it makes sense to clean those nozzles, conveyor belts and filler valves regularly with pH-neutral cleaning products. This stops all that sticky residue from building up over time. And don't forget those monthly checks on seals and gaskets either because nobody wants leaks messing up production runs. Most big-name equipment makers actually suggest following the original equipment manufacturer's schedule pretty closely. Take CIP spray balls for instance - these things should really be swapped out about every six months if we want to keep everything flowing properly through the system.

Microbial Testing and Verification of Effectiveness

The ATP bioluminescence method for checking surfaces picks up organic residue about half as fast as those old-fashioned swab culture tests according to the latest Beverage Safety Report from 2024. Plants that run these weekly checks specifically on equipment parts like filler heads and bottle grippers tend to hit around 98% compliance rates with those strict ISO 22000 food safety standards. There's also been some exciting developments recently with these new UV fluorescence scanners that can spot early signs of biofilm growth in really tricky spots such as inside carbonation chambers long before bacteria levels even get close to reaching that critical 10 CFU per square centimeter threshold that most regulations watch closely.

Implementing Hygiene Audit Frameworks

Third-party audits using NSF/3-A SSI checklists uncover 34% more hygiene gaps than internal reviews. Critical audit focus areas include:

- Air quality metrics in filling zones (<100 particles ≥0.5µ/m³)

- Technician glove sanitation frequency (every 30 minutes)

- Lubricant certification for food-grade NSF H1 compliance

AI and Predictive Maintenance: The Future of Hygiene Monitoring

The machine learning systems that look at vibration patterns in filler motors can actually spot potential bearing problems around two weeks before they happen, which stops those pesky metal shards from getting into products. We've got sensors these days that keep an eye on how turbulent the cleaning fluid flows during CIP cycles. When the speed goes above 2.5 meters per second, these sensors give warnings if the spray isn't covering surfaces properly anymore. This helps maintain proper sanitation standards as required by the latest NFPA 70B guidelines from 2023. Companies who implemented this tech early on are seeing roughly 40-something percent reduction in unexpected equipment stoppages because they monitor syrup thickness in real-time instead of waiting for issues to pop up.

FAQ

Why is hygiene crucial in soft drink filling machines?

Hygiene is critical because it prevents contamination by microbes like E. coli and Salmonella, which can cause batch recalls and pose a health risk to consumers.

What are the common contamination sources in soft drink filling processes?

Biofilm formation, airborne particulates, lubricant migration, and residual sugars are common sources of contamination.

How does Clean-in-Place (CIP) technology help in maintaining machine hygiene?

CIP systems allow cleaning without dismantling machines, reducing contamination by circulating detergents and sanitizers at optimal temperatures.

What materials are recommended for safe machine operation?

316L Stainless Steel, FDA-Grade Silicone, and PEEK Thermoplastic are recommended for their corrosion resistance and safety.

Table of Contents

- Why Hygiene Is Critical in Beverage Production

- How Machine Hygiene Directly Impacts Product Safety

- Food Safety Regulations and Compliance for Soft Drink Filling Machines

- Common Contamination Sources in Soft Drink Filling Processes

- Effective Cleaning and Sanitization of Soft Drink Filling Machines

- Design and Automation Features That Prevent Contamination

- Monitoring, Maintenance, and Continuous Hygiene Assurance

- FAQ