The Role of Automation in Modern Oil Filling Processes

Understanding Automation in Manufacturing and Its Impact on Industrial Productivity and Efficiency

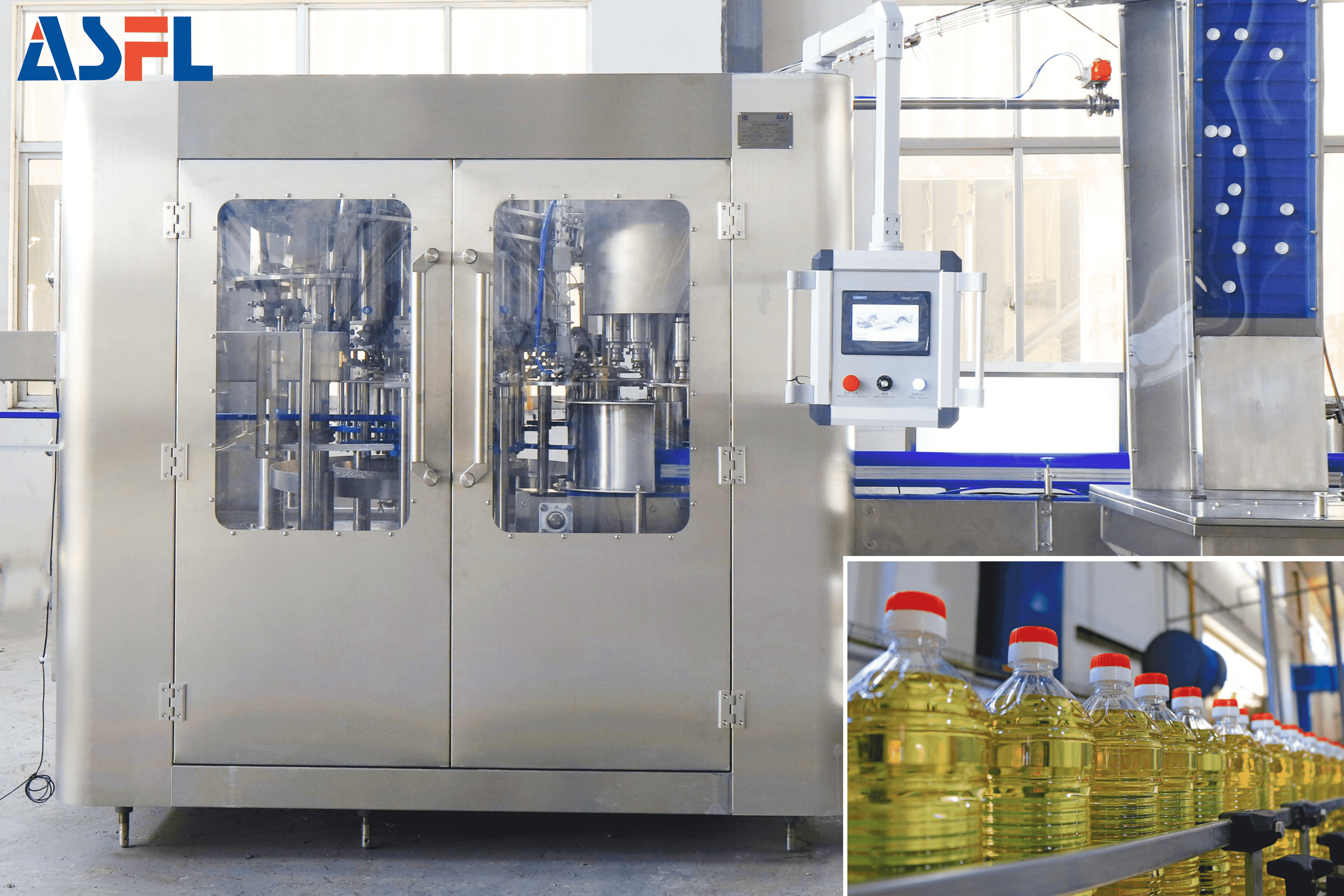

Automation has really changed how things work on the factory floor, especially when it comes to oil production operations. Modern oil filling systems now use those PLCs along with highly accurate sensors to hit around 99.8 percent accuracy most of the time. No more guessing games with measurements since these machines can fill containers at a rate of about 5,000 per hour according to Zenith Filling reports. What this means for plant managers is less need for hands-on labor during production runs. Instead, workers spend roughly 70% of their time checking product quality and doing regular equipment checks rather than standing by the machines all day long.

Transition from Manual to Automatic Oil Filling Machines and Its Effect on Throughput

Switching from manual labor to automation can increase production capacity anywhere from 15 to 20 times over what's possible by hand, industry data suggests. Take oil bottling as an example: while a person might manage around 150 to 300 bottles per hour, an automatic 12-head oil filler can crank out between 3,000 and 5,000 units each hour straight through without getting tired or slowing down. For companies making edible oils, this kind of flexibility makes all the difference when dealing with those unpredictable seasonal rushes in demand that happen every year.

Core Functions of an Automatic Oil Filling Machine in Production Lines

These systems perform three critical tasks:

- Volumetric dosing: Adjust fill volumes (±0.5% accuracy) for diverse oils, from lightweight vegetable oils to viscous lubricants

- Container handling: Synchronize conveyor speeds (0.1–2 m/s) with filling nozzles to prevent spills

- Sealing integration: Combine filling, capping, and labeling in one cycle, reducing downtime by 40%

Studies by Discover Engineering confirm that facilities using integrated automation solutions achieve 18–22% higher annual output compared to semi-automated lines, highlighting the strategic value of end-to-end system upgrades.

Precision and Consistency: Reducing Variability in Oil Filling

Achieving High Filling Accuracy and Product Consistency Through Automation

Today's oil filling machines can hit pretty impressive precision marks between plus or minus 0.2% to 0.5%, thanks to their servo driven volumetric controls and those fancy laser guided detectors for containers. Gone are the days of dealing with that annoying 3% to 5% variation we saw with old fashioned manual methods. Getting consistent fill levels matters a lot these days for meeting regulations and protecting brand image. The automated systems actually have those photoelectric sensors that stop the filling process whenever something gets out of alignment. According to the Packaging Efficiency Report from 2023, this tech cuts down on spills by around 78% compared to what happens with manual operations.

Manual vs. Automated Filling Accuracy: A Comparative Analysis

| Filling Method | Accuracy Range | Waste Per 10,000 Units | Labor Cost/Shift |

|---|---|---|---|

| Manual | ±3% – 5% | 300–500 mL | $220–$280 |

| Semi-Automatic | ±1% – 2% | 100–150 mL | $140–$180 |

| Automatic | ±0.2% – 0.5% | <20 mL | $40–$60 |

The precision gap widens with viscosity—automated machines maintain ±0.3% accuracy even with thick oils like castor or coconut, while manual methods struggle beyond ±7%.

Case Study: 99.8% Filling Precision in an Edible Oil Production Line

A sunflower oil facility reduced fill-volume deviations to 0.2% after deploying automatic oil filling machines with flow-meter technology. Key outcomes:

- 30% decrease in annual product waste (4,200 liters saved)

- 100% compliance with EU filling regulations (2023 audit)

- Elimination of customer complaints about underfilled bottles

This precision enables the facility to allocate 85% fewer quality-control staff to filling operations.

Minimizing Waste and Material Loss with Automated Filling Systems

How Automatic Oil Filling Machines Reduce Spillage and Overfilling

Automated oil filling systems eliminate manual measurement errors through precision flow meters and weight-based sensors. Closed-loop controls adjust dispensing volumes in real time, while no-drip nozzles prevent residual leakage. These features reduce spillage by 15–20% compared to manual methods, according to 2023 liquid packaging industry benchmarks.

Data Insight: 30% Reduction in Material Waste Post-Automation

A 12-month study of 45 bottling plants revealed that facilities using automatic oil filling machines reduced product waste by an average of 30% (Food Production Journal, 2023). This improvement stems from reduced overfilling incidents and minimized liquid retention in transfer lines, directly lowering raw material costs.

Link Between Filling Accuracy and Long-Term Waste Reduction

Precision automation creates compounding savings: a 0.5% improvement in filling accuracy reduces annual waste by 18 metric tons in a mid-sized edible oil facility. Modern systems maintain ±0.25% volume consistency across 10,000+ cycles, preventing underfills and rejected batches that contribute to long-term waste accumulation.

Lowering Labor Costs and Enhancing Operational Efficiency

Impact of oil filling machine automation on labor demand and costs

Oil filling machines today are changing how factories operate because they take over those boring, repetitive jobs that people used to do manually. We're talking about things like placing bottles just right, sealing caps properly, and keeping track of production batches. According to some research done last year, companies that switched to automated systems saw their labor expenses drop anywhere between 35% and almost half what they were before. One company making edible oils actually managed to get rid of six full time workers during each work shift. The biggest plus? No more mistakes when measuring volumes or dealing with inconsistent speeds. Plus, workers aren't lifting those heavy containers anymore, which means fewer back problems and other injuries down the line.

Real-world labor savings in bottling and packaging facilities

Manufacturers across the food processing sector are finding new jobs for about 70 percent of their old line workers once they bring automation into play. Take this sunflower oil facility as an example they cut costs by around $220 thousand each year after swapping out four manual stations for one fully automated system that cranks out 150 bottles per minute nonstop. The machines just keep running through lunch breaks and shift changes too, which means plants can produce anywhere between 18 to maybe even 25 percent more product every day than when humans were doing all the work at their own pace. Some operators actually prefer these setups because there's less downtime and fewer quality issues creeping in during those tired afternoon hours.

Reallocating workforce to higher-value tasks

When machines take over routine tasks, workers get to spend their time on things that really matter quality checks, fine tuning equipment performance, and keeping everything running smoothly before breakdowns happen. At one plant, they took those extra hours saved from automation and put them into training programs for employees. The results? Their Overall Equipment Effectiveness numbers went up by around 15%. What this basically means is that instead of just paying people to show up, companies are now investing in skills development that actually makes production better day after day.

Smart Technology Integration and Future Trends in Oil Filling Machines

Key Technologies Powering Modern Automatic Oil Filling Machines

Modern oil filling machines leverage cutting-edge technologies to optimize performance. Servo-driven dosing systems achieve ±0.5% volume accuracy, while touchscreen PLCs enable operators to store 200+ product recipes. Advanced pressure sensors reduce foaming by 40% compared to traditional pneumatic systems. Key innovations include:

- Self-cleaning nozzles minimizing cross-contamination risks

- Vision-guided filling heads adjusting to container imperfections

- RFID-tagged containers enabling batch-specific parameter adjustments

IoT and AI in Oil Filling Systems: Real-Time Monitoring and Control

Industrial IoT transforms oil filling lines into data hubs, with smart sensors tracking viscosity, temperature, and flow rates at 50 ms intervals. AI algorithms analyze historical data to:

- Predict optimal filling times with 98.7% accuracy

- Detect micro-leaks 83% faster than manual inspections

- Automatically adjust parameters for seasonal oil density variations

A 2023 study of 42 bottling plants showed AI-integrated systems reduced unplanned downtime by 25% while maintaining 99.4% OEE (Overall Equipment Effectiveness).

Robotics and Smart Conveyors: Advancing Automation in Filling Lines

Collaborative robots (cobots) now handle:

- Precise bottle positioning at 1,200 units/hour

- Seamless transitions between 50ml–5L container formats

- Immediate rejection of underfilled units with 0.02mm precision

Modular conveyor systems with embedded weight sensors have reduced line jams by 68% in high-speed environments. These systems automatically recalibrate when switching between glass, PET, or metal containers.

Future Outlook: Self-Diagnosing Machines and Predictive Maintenance

Next-generation oil filling machines will feature:

- Vibration analysis chips predicting motor failures 400+ hours in advance

- Self-lubricating mechanisms extending service intervals by 3.2×

- Blockchain-integrated quality logs for enhanced supply chain traceability

Manufacturers adopting these technologies report 19% lower lifecycle costs and 31% faster new product integration cycles compared to conventional systems.

FAQ Section

What is the role of automation in oil filling processes?

Automation in oil filling processes improves precision, consistency, and efficiency by using technologies like PLCs, advanced sensors, and robotics to reduce human error and increase production capacity.

How accurate are modern oil filling machines?

Modern oil filling machines achieve filling accuracy between ±0.2% to 0.5%, significantly reducing product waste and ensuring compliance with regulatory standards.

What are the key benefits of automated oil filling systems?

Some key benefits include increased production speed, reduced labor costs, minimized material waste, and improved product quality due to consistent filling volumes.

How do automated systems lower labor expenses?

Automated systems take over repetitive tasks, allowing companies to reduce workforce size and reallocate employees to higher-value tasks like quality control and equipment maintenance.

What future technologies are being integrated into oil filling systems?

The future of oil filling systems includes self-diagnosing machines, predictive maintenance, IoT integration, blockchain-enabled traceability, and AI-powered real-time monitoring to further optimize operational efficiency.

Table of Contents

- The Role of Automation in Modern Oil Filling Processes

- Precision and Consistency: Reducing Variability in Oil Filling

- Minimizing Waste and Material Loss with Automated Filling Systems

- Lowering Labor Costs and Enhancing Operational Efficiency

- Smart Technology Integration and Future Trends in Oil Filling Machines

- FAQ Section