Space Efficiency Through Integrated Monoblock Design

Reduction in Production Line Footprint by Replacing Multiple Standalone Machines

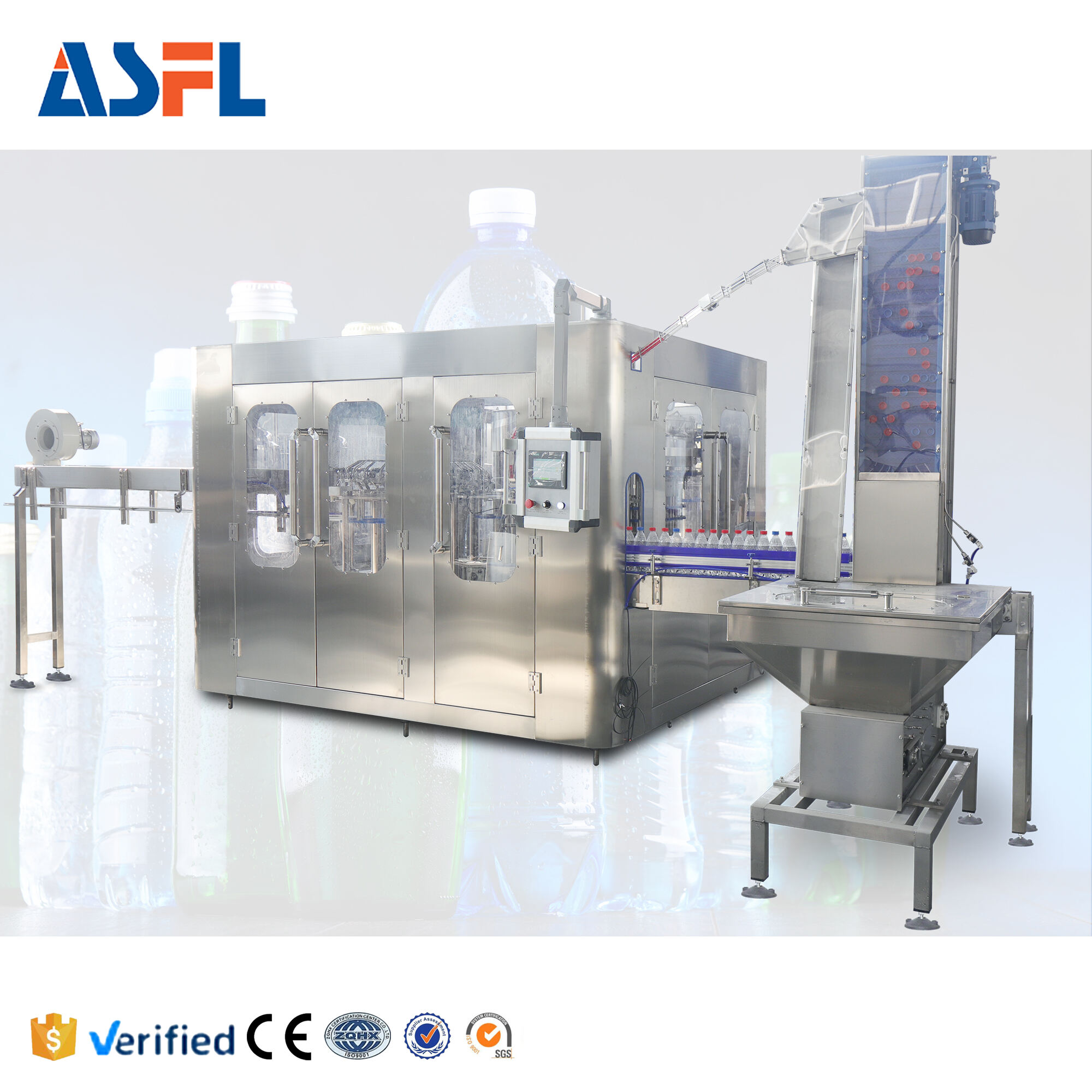

Most traditional beverage plants still run with separate machines for cleaning bottles, filling them, and putting on caps. Each machine needs its own spot on the factory floor plus extra space around it for safety reasons and conveyor belts between them. All this takes up way more room than necessary. Monoblock filling systems solve this problem by combining those three steps into one compact machine. They get rid of duplicate parts like extra frames, motors, and all those transfer areas that just sit there taking up space. According to some industry numbers I've seen, these integrated systems can cut down the overall production line length by about 40%. Plus they save money too since there are 30% fewer electrical and air connections needed. And best of all, factories gain back precious floor space when they remove those middle transfer points, which can be used for storing inventory or setting up other production lines.

Compact Design vs. Traditional Separate Units: Measured Space Savings in Beverage Facilities

| Layout Factor | Traditional Units | Monoblock System | Savings |

|---|---|---|---|

| Line Length | 18–22 meters | 10–12 meters | 45% |

| Conveyor Systems | 3–4 sections | 1 integrated | 70% |

| Utility Access Points | 9–12 | 4–6 | 50% |

| Space utilization metrics based on carbonated drink facility audits |

The compact nature of monoblock systems comes from their vertical design and shared drive components. Standalone equipment needs those big open spaces around them for technicians to work on, but these integrated systems can be serviced at one central point. Many beverage companies have found they actually get about 15 to 20 percent more usable space once they switch over. That makes a huge difference in city locations where landlords charge over two hundred dollars per square foot every year. Getting rid of those transfer buffers between machines cuts down on mistakes during product handling too. Some recent industry reports show error rates drop by roughly 22 percent when using this setup.

Case Study: Space Optimization in a 300ml–5000ml Carbonated Drink Production Line

A soda maker running out of room in their cramped 5,000 square foot plant was struggling with old equipment setup where rinsing, filling, and capping machines took up nearly 28 meters of floor space. When they switched to a monoblock system, the production line shrank down to just 15 meters long, cutting space usage by almost half at 46%. This freed up around 300 square feet, which is about 15% of their whole production area. They used this extra room to install an inline labeling machine that had been on their wish list for years. Operators also noticed changeover times went down by roughly 35% because everything now worked together on a single platform instead of having to move between separate machines. Six months after making these changes, the company saw an impressive 18% boost in total output without needing to expand their facility at all.

Time Savings via Automated and Synchronized Workflows

Elimination of Transfer Points Between Rinsing, Filling, and Capping

Monoblock systems get rid of those pesky bottlenecks that plague traditional multi-machine production lines. They bring together rinsing, filling, and capping all in one neat package that works as a single synchronized unit. Think about it containers just keep moving along without stopping at each stage. No need for waiting in line or getting passed around between machines. The continuous flow really makes a difference too cutting down cycle times by somewhere around 40% when compared to separate modular equipment. Less downtime means fewer problems with things getting stuck because of misalignment issues. And let's not forget automation plays a big role here too. Manual handling drops off dramatically about three quarters less work for operators who can now spend their time watching over product quality instead of constantly moving containers from one spot to another.

Production Speed and Efficiency: Industry Benchmarks for Monoblock Drink Filling Machines

Monoblock drink filling machines can actually boost production rates by around 20 to 50 percent compared to older setups because everything runs continuously and stays in sync. Looking at industry numbers, we typically see speeds ranging from 150 to 300 bottles per minute when handling carbonated drinks in sizes between 300ml and 5000ml. That's pretty impressive when compared to separate line setups which only manage about 90 to 200 bottles per minute. What makes this possible? Well, these systems share servo drives that keep the conveyor belts perfectly timed with the filling valves and capping mechanisms. There are simply fewer components involved, so maintenance breaks down less often about 30% less downtime according to reports. Plus, those programmable logic controllers let operators switch between different bottle formats quickly. This means smaller craft producers can produce limited runs at speeds close to what big manufacturers achieve, without having to spend time reconfiguring equipment between batches.

Engineering Principles Behind Monoblock Integration

Modular Synchronization and Shared Drive Architecture Reducing System Redundancy

The design of monoblock drink filling machines focuses on true integration beyond mere physical assembly. These systems synchronize all the different parts – from cleaning bottles to actually filling them and then putting caps on – through one central control system called a PLC instead of having separate motors for each step. According to Packaging Efficiency Review in 2023, this approach cuts down on about 40% fewer moving parts compared to older models. When manufacturers share common motors and conveyor belts between processes, they save energy while also making breakdowns less likely. Maintenance bills drop around 25% and production time goes up roughly 18%. What really makes these machines stand out though is how quickly operators can switch between products. There's no need to tweak settings when changing from one beverage type to another since everything works together as a single unit. This means factories stay productive even during product changes without sacrificing quality or taking up extra floor space.

Real-World Applications Across Beverage Production Scales

Efficiency in High-Mix, Low-Volume Craft Beverage Operations Using Drink Filling Machine Systems

Craft beverage makers who work with all sorts of small batches—from tangy kombucha to fizzy hard seltzers—find that the monoblock machine offers some serious advantages. When everything from cleaning bottles to filling them and putting on caps happens in one single unit, it takes up way less space on the factory floor compared to separate machines. We're talking about cutting down required area by almost half, which matters a lot for tiny breweries or packaging companies stuck in tight city spaces or temporary locations. The quick swap-out parts let operators switch from one recipe to another or change bottle sizes easily (think 300ml bottles to those big 5 liter containers). And when the whole system works together automatically, switching between different products gets done 30 to 50% faster than before. For businesses making lots of different products but not huge volumes of each, this kind of flexibility means getting new drinks out there quicker, saving money on each batch produced, and being able to respond to market changes without having to buy expensive duplicate equipment lines.

FAQ

What is a monoblock filling system?

A monoblock filling system is an integrated machine that combines the processes of rinsing, filling, and capping beverages, replacing separate standalone machines for each step, thereby saving space and improving efficiency.

How does the monoblock system save space compared to traditional setups?

The monoblock system reduces space by integrating multiple functions into a single unit, eliminating the need for large transfer areas, multiple machines, and extra conveyor systems, which results in up to 45% space savings.

What are the advantages of using a monoblock system over separate machines?

Advantages include reduced floor space usage, lower maintenance and operational costs, quicker product changeovers, and improved production speed and efficiency due to synchronized workflows and fewer transfer points.

Can monoblock systems handle various bottle sizes and drink types?

Yes, monoblock systems offer flexibility with quick swap-out parts and programmable logic controllers, allowing operators to easily switch between different bottle sizes and drink types without reconfiguring equipment.