Understanding Bottle Filling Machine Changeover Fundamentals

What Determines Format Changeover Times for Filling Machines?

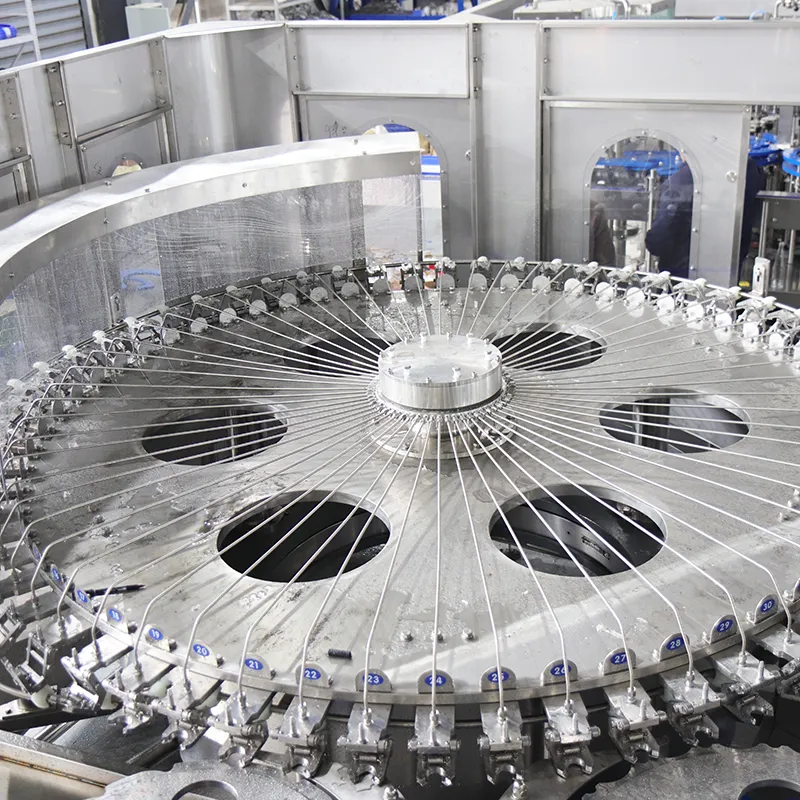

Three main things determine how long it takes to switch between production runs: the size of bottle necks, how adjustable the machines are, and whether there are preset configurations ready to go. According to research published by the Packaging Efficiency Institute last year, plants that stick with standard bottle neck sizes saw their changeover times drop by around 37 percent when compared to facilities dealing with all sorts of odd shapes. Most of the lost time during these switches actually comes from having to tweak things like starwheel guides, set the right height for filling valves, and adjust capping heads manually. Some industry reports suggest this manual work accounts for roughly two thirds of all downtime in packaging operations. The Food Processing Journal mentioned similar findings back in 2023 too.

Industry Benchmarks for Bottle Size Changeover Efficiency

The best beverage production facilities can switch between PET bottle sizes in just 30 to 45 minutes thanks to their modular tools and well-trained staff. Things look very different at plants still using manual methods though. These older operations typically take around 2 hours and 20 minutes to complete each transition, which according to Ponemon's research from last year adds up to about $740,000 lost every year in productivity alone. Modern automated solutions have changed the game completely. Some advanced systems can handle container changes in under 12 minutes when dealing with similar neck diameters, giving companies a real edge in terms of efficiency and output capacity.

| Adjustment Type | Manual Time | Automated Time | Downtime Cost |

|---|---|---|---|

| Conveyor Width | 22 min | 3 min | $1,650/hr |

| Filling Nozzle Height | 18 min | 1.5 min | $1,240/hr |

| Capping Head Swap | 34 min | 5 min | $2,110/hr |

The Role of Machine Adjustability in Reducing Downtime

Modern bottle filling machines equipped with quick-release clamps and programmable height sensors reduce adjustment labor by 58%. According to a 2023 Automation World analysis, installations using self-centering guide rails and sensor-driven nozzle alignment cut format change errors by 91%. High-mix producers benefit most: machines maintaining ±0.5mm positional accuracy during swaps restart 89% faster.

Leveraging Recipe-Based Controls for Faster Bottle Size Transitions

How Recipe-Based Controls Streamline Bottle Filling Machine Adjustments

Recipe-based controls eliminate manual recalibration by storing fill volume, conveyor speed, and indexing intervals for each bottle size. A 2024 system analysis found these controls reduced changeover time by 43% compared to manual methods, as operators bypass up to 80% of mechanical adjustments via preset configurations.

Implementing Programmable Bottle Gating System for Quick Transitions

Servo-driven programmable gating systems reconfigure guide rails and stoppers in under 60 seconds, supporting formats from 100ml travel bottles to 2L containers. These systems maintain ±0.5mm positioning accuracy even at high speeds, preventing jams across diverse shapesâincluding oval cosmetic bottles and square juice cartons.

Storing and Recalling Settings for Repeatable Changeovers

Advanced fillers store over 200 preset configurations for neck finishes, shoulder angles, and cap types. Programmable logic controllers (PLCs) enable one-touch recall of nozzle heights, capper torque settings, and sensor thresholdsâessential when switching between fragile glass perfume bottles and durable HDPE chemical jugs.

Executing Mechanical and Accessory Adjustments Efficiently

Reconfiguring Conveyor Widths and Starwheel Guides

Precise conveyor rail and starwheel guide alignment ensures smooth transitions between bottle sizes. For PET lines, just a 2 mm misalignment can increase jamming risk by 30% (Packaging Digest 2023). Use calibrated scale markings to verify spacing before securing components.

Adjusting Filling Valves for PET Bottle Size Variability

Valve stroke length and actuation timing must be recalibrated when shifting between 250 mL and 1 L bottles. Modern systems allow operators to set fill volumes with ±1% accuracy via touchscreen interfaces, minimizing measurement errors during changeovers.

Swapping Nozzles, Guards, and Height Sensors for New Formats

Quick-release mechanisms let technicians replace nozzles and optical sensors in under 90 seconds. Prioritize modular components compatible with 60â120 mm neck finishes to avoid full disassembly.

Matching Accessories to Bottle Neck and Shoulder Profiles

Select collar guides and capping heads based on shoulder angleâtypically 10°â45° for beverage bottles. Mismatched profiles account for 27% of sealing failures in high-speed fills, making dimensional compatibility vital for leak prevention.

Streamlining Preparation and Post-Changeover Validation

Checklist for Pre-Changeover Inspections on Bottle Filling Machine

Synchronizing Tooling, Personnel, and Spare Parts Ahead of Changeover

Pre-staging gripper jaws, height sensor shims, and neck ring adapters cuts search time. Leading plants use shadow boards with RFID-tagged tools to ensure 100% availability of changeover kits. A 2023 Filling Systems Institute study found synchronized teams complete adjustments 23% faster than unstructured crews.

Minimizing Waste with Dry Runs Before Full Production

Dry runs validate starwheel timing and rejection gate performance without product loss. This step catches 91% of alignment issues that lead to overfills in narrow-neck glass bottles. Operators typically run 5â10 cycles at reduced speed, checking for jams and nozzle centering.

Validating Fill Levels and Overflow Control Post-Adjustment

Post-changeover quality verification uses statistical process control (SPC) to ensure fill volumes stay within ±1.5% variance. Advanced lines integrate inline checkweighers that automatically correct piston strokes when weights exceed ISO 9001 limits. Plants using real-time validation reduce material waste by 18% versus manual sampling.

Improving Long-Term Changeover Performance Through Documentation and Data

Documenting Each Step to Improve Future Format Changeover Times

When companies keep good records, they end up with templates that can be reused over and over again for standard formats. This saves time when switching between different production runs. Plants that have adopted electronic work instructions (EWI) systems are seeing around 22 percent speed improvements during these transitions. No more guessing games with things like where to position collar guides or set nozzle heights. Just follow what's already been documented. Keeping track of specific numbers like torque specifications and vacuum levels makes sure everyone follows the same procedures no matter who is working on the line. This kind of consistency has led to about 14% fewer mistakes needing correction in facilities dealing with lots of different product SKUs according to PMMI research from last year.

Using Data from Past Changeovers to Predict Maintenance Needs

Looking at past changeover records shows some interesting patterns worth noting. Motor resistance tends to climb when aligning starwheels, while valves show signs of wear after repeated viscous fill operations. Facilities that keep an eye on hydraulic pressure fluctuations and variations in clamp force have seen their unplanned downtime drop by around 31% simply by swapping out O-rings and gaskets before they fail. According to the latest Beverage Industry Report from 2023, plants using AI for predictive maintenance cut down on those annoying format change delays caused by mechanical problems by nearly 19% each year. These numbers highlight why so many manufacturers are investing in smarter monitoring systems these days.

Balancing Flexibility and Reliability in Bottle Filling Machines

Modular design systems work well for everything from small 100ml vials right up to those big 3 liter containers, but when companies get too specialized with their equipment, maintenance starts costing a lot more money. The best packaging lines out there manage to keep around 80% of their components standardized. Think universal filler heads that can handle multiple sizes, adjustable rails that adapt to different container shapes. Only about 20% needs to be specific to particular formats like those tricky neck grippers for certain bottle types. This approach keeps fill valves responding fast enough under 200 milliseconds between different product SKUs, and tooling costs stay reasonable at less than $1,200 per format according to Packaging World's latest report. Real world testing shows these balanced systems hit an impressive 93% overall equipment effectiveness even when switching between multiple formats throughout production runs.

FAQ Section

What is a bottle filling machine changeover?

A changeover in bottle filling machines refers to the process of switching the production line from one bottle format or size to another. This involves adjusting the machine settings and components to accommodate different container shapes and sizes.

Why are changeovers important in beverage production?

Changeovers are crucial because they allow manufacturers to efficiently switch between different product runs, optimizing the use of equipment and minimizing downtime, which ultimately leads to increased productivity and reduced costs.

How do recipe-based controls aid in faster changeovers?

Recipe-based controls store specific settings like fill volume and conveyor speed for each bottle size. Operators can quickly switch between these presets, significantly reducing manual adjustments and speeding up the changeover process.

What benefits do automated systems provide in bottle filling machine changeovers?

Automated systems significantly reduce the time and labor involved in changeovers by using modular components and programmable controls. This leads to faster transitions, fewer errors, and increased efficiency and output capacity.

Table of Contents

- Understanding Bottle Filling Machine Changeover Fundamentals

- Leveraging Recipe-Based Controls for Faster Bottle Size Transitions

- Executing Mechanical and Accessory Adjustments Efficiently

- Streamlining Preparation and Post-Changeover Validation

- Improving Long-Term Changeover Performance Through Documentation and Data

- FAQ Section