Today's carbonated drink filling equipment relies on counter-pressure tech to keep things at around 3 to 5 bars inside, which stops all that precious CO2 from escaping when moving liquids around. When the pressure stays balanced between the bottles themselves and those big storage tanks, manufacturers can hang onto about 98 percent of their carbonation. That beats out old fashioned atmospheric methods where only about 78% makes it through according to Beverage Production Quarterly folks. The real benefit? Drinks stay bubbly as promised while cutting down wasted product somewhere between 12 and maybe even 15% for each production run.

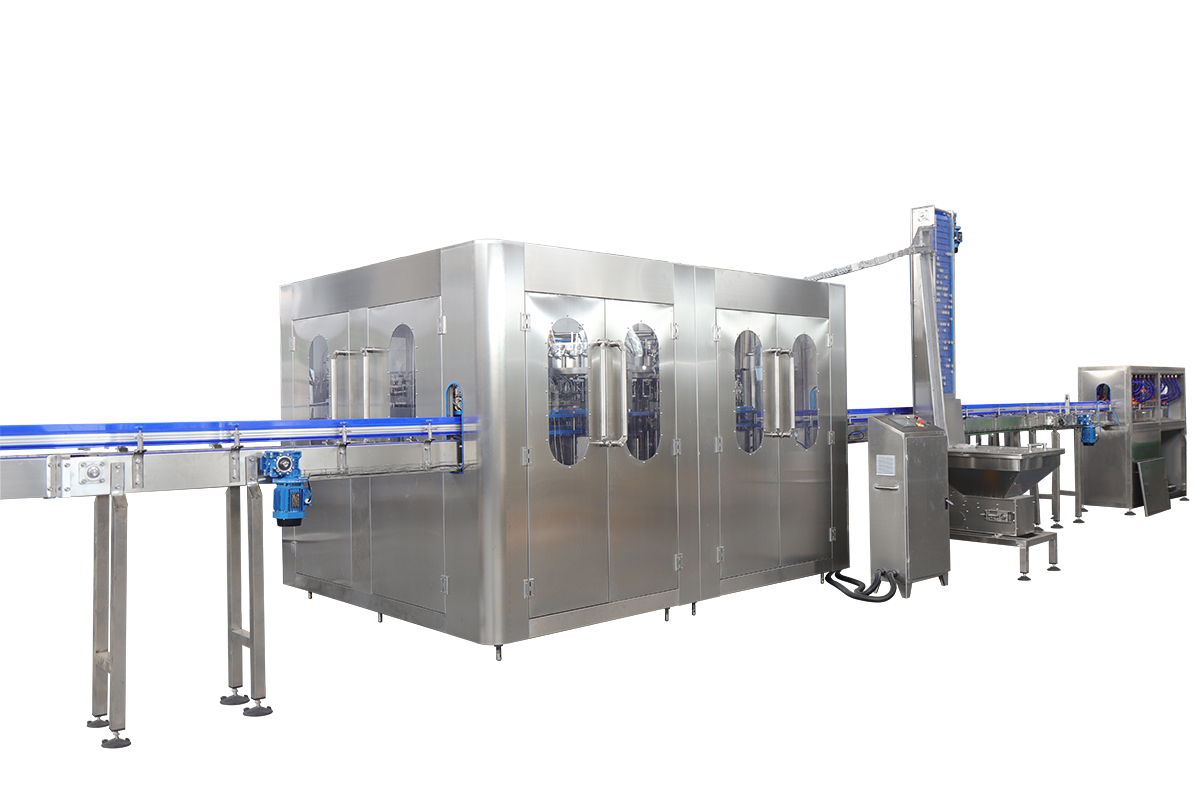

Every high-efficiency filling line integrates four synchronized subsystems:

Industry analyses show that seamless integration of these modules reduces mechanical downtime by 40% compared to standalone or disjointed setups.

Advanced lines now feature integrated quality assurance technologies:

| Technology | Function | Defect Detection Rate |

|---|---|---|

| Vision scanners | Cap alignment verification | 99.7% |

| Laser leak detectors | Monitor pressure loss | 0.02 bar/sec sensitivity |

| X-ray inspectors | Validate fill levels | ±0.5mm accuracy |

Together, these systems reduce recall risks by 32% and maintain product loss below 0.1% over standard 8-hour shifts.

Getting the best results from carbonated drink filling equipment really comes down to how we organize the different parts of the process. When manufacturers split their production floor into separate zones for cleaning bottles, filling them, putting on caps, and quality checks, it cuts down on workers moving around too much and keeps everything flowing in order. Some research published last year showed that this kind of zoned layout actually cut down on conveyor belt backtracking by about a third compared to old fashioned straight line setups, which matters a lot when trying to keep carbon dioxide levels stable in the drinks. Putting together the rinsing station, filler machine, and capper all within roughly six meters makes transferring containers between steps much smoother. According to Beverage Production Journal from 2023, this configuration can increase production speed by nearly 11 percent, something that adds up over time for plant managers watching their bottom lines.

More and more manufacturers are turning to 3D simulation software such as FlexSim and AnyLogic when planning their production lines. These programs look at things like conveyor belt angles, where filler valves should go, and how often emergency stops need to be placed around the factory floor to spot potential trouble spots. A bottling company somewhere in Europe actually saved themselves quite a bit of time by creating a digital twin model of their facility. They moved around some inspection sensors and adjusted the position of their filler heads, which got rid of this annoying 18 minute delay happening every single hour because equipment wasn't lined up properly according to Food Engineering Report from last year. The numbers back this up too - factories that use simulation for design usually hit between 92% and almost 97% efficiency right from the start when making carbonated drinks.

A soft drink manufacturer based in the Midwest recently overhauled their old factory floor plan. Instead of having separate areas for rinsing, filling, and capping operations, they grouped these machines together into what they call "cells." This new arrangement reduced how far containers had to move between processes by about 41 meters each time they ran a production batch. Plus, it made sense to share things like compressed air lines and cleaning systems across multiple machines. The results? Their unexpected equipment breakdowns went down quite a bit - from around 14.7 hours lost every week to just 11.5 hours. Switching between different product runs also became faster, improving changeover times by roughly 15%. Another smart move was installing those hexagonal shaped workstations throughout the plant. These gave maintenance staff complete access to machinery from all sides while keeping production running smoothly. Pretty impressive stuff actually, since nearly 4 out of 10 leading bottling companies have started using similar designs according to Beverage Industry Trends report from last year.

Modern carbonated beverage filling machines now reach around half a percent accuracy in volume thanks to servo driven valves and vision guided packaging systems. This basically gets rid of all those little inconsistencies that used to happen when people were manually handling things. The machines have built in weight sensors plus some pretty smart pressure compensation stuff going on behind the scenes. They keep CO2 levels right around 0.2 grams per liter even when cranking out 24 thousand bottles an hour flat out. Looking at what's happening in the industry these days, companies switching to fully automated portioning systems are seeing about an 18% drop in wasted ingredients compared to their older semi automatic equipment. And there's this inline monitoring for dissolved oxygen too, keeping it below 2 parts per million so every batch tastes just like the last one.

One European beverage company boosted its production output significantly by linking together a massive 144-valve rotary filler system with automated robotic palletizers using flexible PLC technology. When the filling and capping operations started working in real time harmony, downtime dropped around 30%, pushing overall equipment effectiveness to nearly 99.5% during busy periods. Smart planning around automation allowed for about a quarter faster changes between different product types thanks to better recipe management systems. This setup lets them run both small 250ml cans and large 1 liter PET bottles side by side on the same production line without major interruptions.

Over 67% of new installations now include vibration analysis sensors and infrared CO2 leakage detectors, with predictive analytics cutting unplanned downtime by 41% (Food Engineering 2023). IoT-enabled flow meters power self-calibrating nozzles that adjust automatically for syrup viscosity changes, sustaining ±1% fill accuracy across 8,000 operating hours between service intervals.

Changing from 250ml PET bottles to those big 1L glass containers creates real headaches for carbonated drink filling equipment. According to a survey done in 2023 across the industry, these unexpected format switches actually cut into production by about 14% each day because of all the time needed to recalibrate machines and do those tedious manual fixes. There are several problems here really. The neck grippers just don't fit right, the nozzles come in different sizes, and keeping that CO2 pressure stable within a narrow range of plus or minus 0.2 bar while switching formats is practically impossible without affecting how good the product tastes and looks.

Top-performing systems address these issues with:

A 2022 case study showed PLC-integrated filling lines maintained 98.4% OEE during shifts involving eight different product variants.

The adoption of flexible systems delivers measurable gains:

| Metric | Before Implementation | After Implementation |

|---|---|---|

| Average changeover time | 37 minutes | 7 minutes |

| Weekly production runs | 18 | 34 |

| Annualized capacity | 1.2M cases | 2.8M cases |

This scalability allows producers to manage seasonal SKUs alongside core products without adding new filling lines, with automation upgrades typically delivering ROI within 11 months.

Getting maximum performance out of carbonated drink fillers really comes down to how well the different parts work together at the same time. The filler speed needs to match up just right with what the capping system can handle and how fast the conveyor belts move along the line. These days most modern production lines have these fancy PLC control systems that let operators tweak settings on the fly so everything keeps moving smoothly. Take the sensors for example they'll actually cut back on how much product gets poured into bottles when the labeling machines start lagging behind. This helps avoid those nasty bottle jams and reduces waste from spills, even though it might mean slightly lower speeds during peak demand periods.

Analysis of 12 bottling plants revealed that facilities optimizing synchronization between fillers and packaging units reduced downtime by 19% and increased output by 30% (Beverage Production Quarterly 2023). This improvement stems from eliminating speed mismatches that previously led to bottlenecks or underused equipment.

Manufacturers across the industry are increasingly turning to modular design approaches that let them scale operations gradually as market needs expand. The system includes things like replaceable fill heads and adjustable carbonation settings, which means production lines can handle different container sizes or product formulas without needing complete overhauls. Looking at what's happening in the sector right now, companies that implement these flexible solutions tend to save around 35 to 40 percent on equipment costs over time when compared to traditional setups that require whole new installations for every change.

Counter-pressure filling systems maintain CO2 levels by balancing pressure between bottles and storage tanks, thus preserving carbonation.

Modular tooling reduces format switch time from 45 minutes to under 9 minutes, enhancing efficiency and flexibility.

Zoning organizes production processes into dedicated areas, reducing unnecessary movement and increasing workflow efficiency.

Automation reduces variability, enhances accuracy, and improves overall efficiency, leading to consistent output and scalability.