Karbondioksitli İçecek Şişelerinin Kapatılması Sırasında Yaşanan Zorluklar

Karbondioksitli İçeceklerin Kapatılması Sırasında Basınç Yönetimi

Karbon dioksit içeceklere çözündüğünde 4,8 bar'ın veya yaklaşık 69,6 psi'nin üzerinde iç basıncın oluşmasına neden olur. Bu, üreticilerin fazla basınç birikmeden CO2'yi içeride tutabilmek için gerçekten iyi sızdırmazlık sistemlerine ihtiyaç duymasını gerektirir. İçecek kabın içine doldurulduktan sonra kapatılmasına kadar 700 milisaniyenin üzerinde bile olsa küçük bir gecikme yaşanırsa, değerli karbonasyonun yaklaşık %8'i kaybedilir ve bu da içeceğin tadı üzerinde kesinlikle olumsuz etki yaratır. Günümüzün modern karbonatlı içecek ekipmanlarında, kapları yalnızca yaklaşık 100 milisaniyede kilitleyebilmeleri için konveyör bantlarıyla uyum içinde çalışan servo kontrollü kapama sistemleri bulunur. Şişelerin ezilmesi ya da fazla basınçtan dolayı kapakların fırlaması gibi sorunları önlemek amacıyla çoğu üretim hattı, artı eksi 0,2 bar aralığındaki değişikliklere dayanacak şekilde ayarlanmış basınç tahliye valfleri kurar. Bu küçük ayarlamalar, ürünlerin tüketici için tutarlı ve güvenli kalmasında büyük fark yaratır.

Yüksek Basınçlı Ortamlarda Tork ve Sızdırmazlık İyiliği

Bu tür işlemlerde doğru tork miktarını uygulamak çok önemlidir. Eğer biri yeterli kuvvet uygulamaz ve 28 mm'lik PET kapaklarda 8 Newton metre'nin altına düşerse, karbon dioksit kaplardan kaçmaya başlar ve bu da her ay en az %2 kayba neden olur. Ancak diğer yönde fazla ileri gitmek de iyi değildir. 12 Nm'den daha fazla tork uygulamak şişe boyunlarındaki dişleri hasarlandırabilir. Modern kapaklama ekipmanları, bu sorunu, infrared sensörlerle eşleştirilmiş şekil değiştirme ölçerler (strain gauge) kullanarak çözer ve dakikada 400'den fazla şişe işlerken bile tork seviyelerini yaklaşık %5 doğrulukla korur. Gerçek zamanlı izlemenin sağladığı fark da oldukça etkileyicidir. Çalışmalar, bu sistemlerin eski tip manuel ayarlara kıyasla sızdırmazlık hatalarını yaklaşık üçte ik kadar azalttığını göstermektedir. Bu düzeyde bir iyileştirme, doğrudan daha az reddedilen ürün ve genel olarak daha memnun müşterilere dönüşür.

Karbon Dioksit Basıncı Altında Şişe Kapatma ve Kapların Bütünlüğü

PET şişeler tekrarlanan basınç değişimlerinden geçtiğinde, zamanla kümülatif stres yaşarlar. Gözlemlerimize göre bu plastik kaplar, içindeki CO2 basıncının her 1 bar artışıyla yaklaşık %0,03 oranında dışa doğru genişler. Sızdırmazlık testleri de ilginç sonuçlar ortaya koyar. Korona kapaklar oldukça iyi duruyor ve bir yıl boyunca raf üzerinde durduktan sonra bile yaklaşık %99,4'lük bir sızdırmazlık etkinliğini koruyor. Vida kapaklar ise bazı iyileştirmeler olmadan aynı performansı gösteremiyor. Doğal olarak korona kapakların sunduğu seviyeye ulaşabilmek için daha iyi astar malzemelere ihtiyaçları var. Modern hat içi lazer muayene teknolojisi son zamanlarda büyük ilerlemeler kaydetti. Bu sistemler yalnızca 5 mikrometre çapındaki minik çatlakları tespit edebiliyor. Bu mikroskobik hataların erken fark edilmesi, karbon dioksit seviyesinin haftada yaklaşık yarım puan azalmasına neden olan can sıkıcı yavaş sızıntıların önüne geçer.

Karbonatlı İçecekler için Kapak Uygunluğu ve Sızdırmazlık Gereksinimleri

Şişe Kapakları için Malzeme Seçimi: Plastik ve Metal Performans Karşılaştırması

Çoğu karbonatlı içecek üreticisi, içerikle tepkimeye girmemesi ve hafif olması nedeniyle HDPE ve PP plastik kapaklara güvenir. Metal kral kapaklar, oksijenin içeri girmesine karşı daha iyi koruma sağlar ve bu da plastik alternatiflere göre tatların yaklaşık %28 daha iyi korunmasını sağlar. Ancak günümüzde ko-ekstrüzyon teknolojisiyle üretilen modern plastik kapaklar, milyonda 15'ten az oksijen geçişine izin verir ve bu da gazlı içeceklerin market raflarında taze kalması için yeterli düzeydedir. Farklı kapak türlerini seçerken, birçok üretici PET şişeler için geri dönüşümü daha kolay olan plastik vida kapakları tercih eder. Cam şişeler ise özellikle üst segment markalar veya tüketici tarafından tercih edilen klasik görünüm arayan ürünler için genellikle çelik kral kapaklara bağlı kalır.

Modern Kapatma Sistemlerinin Sızdırmazlık ve Su Geçirmezlik Özellikleri

Modern şişe kapaklarında, karbonatlı suları ve aşırı karbonatlı meşrubatları uygun şekilde kapatmada çok önemli olan yaklaşık 6 bar iç basınca dayanabilen bu gösterişli çok katmanlı contalar bulunur. Yeni termoplastik elastomer astarlar, eski moda kağıt contalara göre CO2'yi yaklaşık %34 daha iyi tutar. İşte ilginç olanı: üreticiler dişleri üst kısımda sıkıştırmayla birleştirdiğinde, çoğu şişe uzun süre tamamen sızdırmaz kalır. Soğuk bir yerde bir gün sonra sıcak koşullarda bırakılsa bile, üç ay boyunca bekletildikten sonra 100 şişeden 99'unun sızmadığı testlerle gösterilmiştir.

Otomatik Karbonatlı İçecek Dolum Hatlarında Kapak Tiplerinin ve Şişe Boyutlarının Değerlendirilmesi

Yüksek hızlarda çalışan döner kapak makineleri, her dakika 1.200 şişenin aktığı tempoya ayak uydurabilmek için yaklaşık artı eksi 0,2 mm'lik oldukça hassas kapak çapı ölçümlerine ihtiyaç duyar. Tork kontrol sistemi ise şişelere kapak eklerken uygulanan basıncı ayarlamada oldukça akıllıca bir iş yapar ve bu basınç küçük 200 ml'lik kaplardan büyük 2 litrelik şişelere kadar tüm kap boyutlarında 12 ila 18 Newton metre arasında değişir. Bu makineleri gerçekten değerli kılan şey, aynı üretim hattında farklı birçok şişe biçimini ve boyutunu kolayca işleyebilme yeteneğidir. Düşünün ki dar boy 330 ml enerji içeceği şişelerinden geniş ağızlı 1 litrelik karbonatlı meyve suyu kaplarına geçiş yaparken hiçbir aksama olmadan süreç devam eder. Bu esneklik, makinenin başlık değiştirme süresini geleneksel sabit başlıklı kapak makinelerine kıyasla dramatik şekilde azaltır—yaklaşık olarak üç kat daha kısa sürede tamamlanır.

ROPP vs Vida vs Krimp: Temel Kapaklama Teknolojilerinin Karşılaştırılması

Gazlı Su Üretiminde Cam Şişeler için ROPP Kapaklama

Gazlı su yapımında cam şişeler için ROPP kapaklama gerçekten çok iyi çalışır. Temel olarak alüminyum kapaklar şişelerin dişli boyunlarına sarılır ve tüketici tarafından aranan ambalajın bozulmadığına dair güvenliği sağlayan conta oluşturur. Her şey doğru ayarlandığında makineler oldukça yüksek basınç koşullarında bile dakikada yaklaşık 100 adet kapak takabilir. Cam, işlem boyunca dişlerin düzgün biçimde korunmasını sağlayacak kadar sert yapıdadır. Bu durum özellikle önemlidir çünkü şişedeki karbondioksit seviyesinin 4,2 barın üzerinde tutulması, müşterilerin içeceklerinden beklediği karakteristik köpüklüğü sağlar.

PET Şişe Dolum Hatlarında Vida Kapağı Teknolojisi

Vidalı kapak, birden fazla kez kullanılabilmesi ve doğru torkta sıkıldığında sürekli sızdırmazlık sağlaması nedeniyle çoğu PET şişe uygulamasında tercih edilen seçenektir. Günümüzün otomatik dolum sistemleri, bu astarsız kapakları genellikle yaklaşık 1,2 ila 2,5 Newton metre kuvvet ile sıkıştırır. Bu tork seviyesi, plastikte gerilim çatlaklarına neden olmaksızın iyi bir sızdırmazlık oluşturacak şekilde kapağı yeterince sıkıştırır. Bu makineler aslında her dakikada 450'den fazla şişeyi işleyebilir. Raf ömrü açısından bakıldığında, PET şişeler için üretilen polipropilen kapaklar, normal HDPE alternatiflerine kıyasla ambalaj içine giren oksijeni yaklaşık yüzde 37 oranında azaltır. Bu durum, depolama ve taşıma sırasında oksidasyondan korunması gereken tatlı karbonatlı içecekler gibi ürünler için büyük fark yaratır.

Özel Karbonatlı İçeceklerde Krimp Kapatma Uygulamaları

Kıvırma kapaklama, el yapımı meşrubatlardaki ve küçük parti kombucha şişelerindeki klasik taç şeklindeki kapakları sabitlemek için oldukça etkilidir. Makine, kıvırma işlemi sırasında yaklaşık 150 ila 220 Newtonluk bir kuvvet uygular ve bu, her zaman tam olarak eşit olmayan zorlu şişe boyunlarıyla başa çıkmaya yardımcı olur. Çoğu sistem, her iki yönde yaklaşık 0,15 mm sapma ile 26 ila 33 milimetre arasında değişen şişe çaplarını kolayca işleyebilir. Bu da ürün tutarlılığının önemli olduğu ancak hacmin çok büyük olmadığı kısa üretimler için özellikle uygundur. Bu kapakların içinde termal yapıştırılmış folyo astarlar varsa, mikroplara karşı yaklaşık %99,97 etkinlikle neredeyse mükemmel bir bariyer oluştururlar. Ayrıca bu durum, gıda güvenliği standartları konusunda ISO 22000'te belirtilen tüm gereksinimleri karşılamaktadır; böylece üreticiler ürünlerinin tüketiciler için güvenli olduğunu bilir.

Kapaklama Yöntemlerinde Hassas Tork Kontrolü

Entegre tork izleme sistemleri, doldurma makinesi sensörleriyle senkronize olarak farklı kapaklama türlerinde hassasiyeti sağlar:

- ROPP uygulamalarında ±0,1 Nm toleransını koruyun

- PET duvar kalınlığına göre torku otomatik olarak ayarlar

- Her 150 ms'de bir kıvırma kapağının hatalarını tespit eder

±0,2 Nm'den fazla tork sapması, PET kaplarda sızma riskini %40 artırır. Modern doğrulama modülleri, saatte 600 şişenin üzerinde üretim hızını korurken hatalı kapakları %98,6 doğrulukla reddeder.

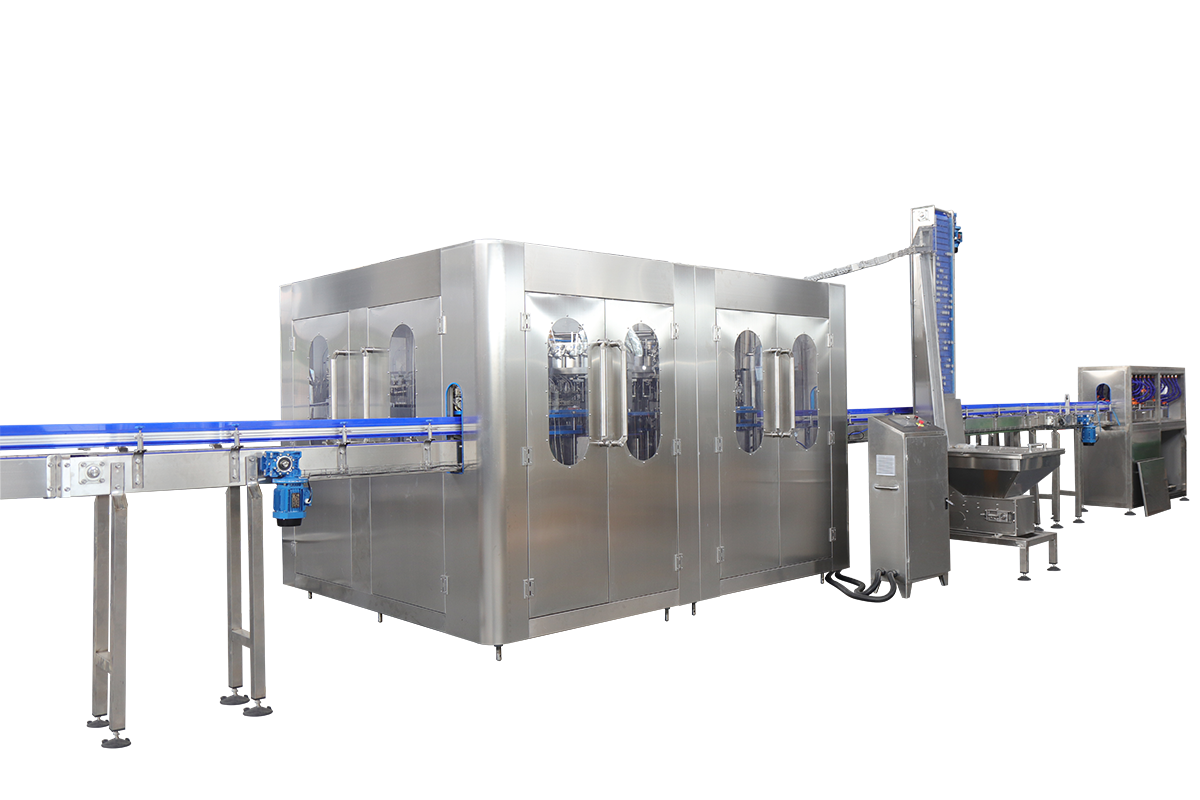

Karbondioksitli İçecek Dolum Makineleri için Otomatik Kapaklama Sistemlerindeki Gelişmeler

Modern karbonatlı içecek dolum makineleri, dakikada 1.200'ye kadar kapak yerleştirebilen ve ±%2 tork doğruluğu sağlayan servo sürülü kapaklama sistemleri kullanır. Bu sistemler, sabit karbonasyon basıncı altında tutarlı kapak kalitesini sağlamak için yüksek hız ile gaz tutumunu dengeleyebilmek adına hassas mekanik yapı ve gerçek zamanlı izlemeyi birleştirir.

Satır İçi ve Döner Çeneli Kapaklama Makineleri

İnterval capping makineleri, değişken şişe aralığı ile düşük-orta hızlı operasyonlara (200–500 BPM) uygundur ve küçük üretim partileri için esneklik sunar. Döner chuck tipi sistemler yüksek hızlı hatlarda (800–1.200 BPM) hakimdir ve çoklu başlıkla eş zamanlı çalışma ile %30 daha yüksek verim sağlar. Ancak bu sistemler, yukarı ve aşağı akım süreçleriyle tam senkronizasyon gerektirir ve standart konteyner formatlarında en iyi şekilde çalışır.

Kapak Kapatma Makinelerini İzleme: Yüksek Hızlı Hatlarda Esneklik ve Hassasiyet

Görüntü kılavuzlu izleme kapak makineleri, tutarsız şişe aralığına dinamik olarak uyum sağlayarak sabit pozisyonlu ünitelere kıyasla ürün reddetme oranını %18 oranında azaltır. Dakikada 1.050 şişeye kadar olan hızlarda, bu sistemler kapak malzemesine ve iç CO₂ basıncına (6–8 PSI) göre gerçek zamanlı tork ayarlamaları yaparak %99,4'lük bir sızdırmazlık oranı korur.

Tek Başlık vs. İzleme Kapak Kapatma Makineleri: Kullanım Alanları ve Verimlilik

Tek başlıklı kapak makineleri, özel içeceklerin küçük partileri için (<5.000 birim/saat) maliyet açısından etkili kalmaya devam eder. Buna karşılık, takip sistemleri durma süresi olmadan 15'ten fazla şişe formatında hızlı değişimi mümkün kılar. Avrupa'nın el yapımı meşrubat üreticilerinde yapılan uygulamalar, dolum ve kapaklama istasyonları arasındaki milisaniye düzeyinde senkronizasyon sayesinde CO₂ sızıntısını %6'dan %1'in altına düşürdü.

Kapatma Kalitesinden ödün vermeden Kapaklama Hızının Optimize Edilmesi

Büyük Ölçekli Karbonatlı İçecek Paketlemesinde Yüksek Hızlı Kapaklama

Modern servo senkronize karbonatlı içecek doldurucular, kapak değiştirirken CO2 kaybını %0,2'nin altında tutarak her dakikada 400'den fazla şişe işleyebilir. Bu makineler, taşıyıcılar dakikada 150 metre hızla ilerlerken bile yaklaşık 0,1 mm doğruluk içinde kalan otomatik izleme kapaklama başlıklarına sahiptir. Bu da şişelerin içindeki karbonasyon nedeniyle sürekli bir basınç varken bile tümünün uygun şekilde kapatılmasını sağlar. Geçen yıl yayımlanan bir araştırmaya göre, sızdırmazlık elemanlarıyla ilgili köpük sorunlarının yaklaşık 10'da 8'i üretim hızı dakikada 300 şişeyi aştığında meydana gelir. Bu yüzden artık birçok tesis, uçuş esnasında ayar yapan özel tork kompanzasyon sistemlerini kurmaktadır.

Gerçek Zamanlı Sızdırmazlık Doğrulaması için Veri Odaklı Tork İzleme

Modern ambalaj hatlarında kullanılan kızılötesi tork sensörleri, üretim hattı sorunsuz şekilde çalışmaya devam ederken sadece 50 milisaniye içinde gevşek kapakları tespit edebilir. Testler, bu sistemlerin özellikle PET şişeler ve alüminyum kutular için eski moda elle yapılan kontrollere kıyasla karbonasyon kaybını yaklaşık %72 oranında azalttığını göstermiştir. Bu teknolojiyi öne çıkaran şey, zamanla ne kadar akıllılaştığıdır. Makine öğrenmesi, 120'den fazla şişe kapağından gelen farklı tork desenlerini okur ve malzemelerin hızlı üretim süreçleri sırasında ısı nedeniyle genleşmesi durumunda ayarları otomatik olarak kendiliğinden uyarlar.

SSS Bölümü

Karbonatlı içecek şişelerinin kapatılması sırasında karşılaşılan yaygın sorunlar nelerdir?

Yaygın sorunlara, zamanlaması iyi olmayan kapak kapatma nedeniyle karbonasyon kaybı, yanlış tork uygulamalarından kaynaklanan conta arızaları ve şişe dişlerinde ya da kapak malzemelerindeki kusurlardan dolayı meydana gelen sızıntılar dahildir.

Tork, şişe kapatmaya nasıl etki eder?

Doğru tork uygulaması, sızdırmaz bir conta sağlamayı sağlar ve CO2'nin kaçmasını önler, şişe boyunlarındaki dişlere zarar verme riskini azaltır ve daha az ürünün reddedilmesine neden olur.

Şişe kapakları için malzeme seçimi neden önemlidir?

Malzeme seçimi, conta kalitesini ve oksijen girişi direncini etkiler; bu da ürün tazeliklerini etkiler ve aromaların korunmasına yardımcı olur.

Otomatik kapaklama sistemlerinde hangi gelişmeler yapılmıştır?

Modern sistemler, yüksek hızlarda bile geliştirilmiş conta kalitesi ve azaltılmış CO2 kaybı için hassas mekanik, gerçek zamanlı izleme ve servo sürüşlü kapaklama özelliklerine sahiptir.

İçindekiler

- Karbondioksitli İçecek Şişelerinin Kapatılması Sırasında Yaşanan Zorluklar

- Karbonatlı İçecekler için Kapak Uygunluğu ve Sızdırmazlık Gereksinimleri

- ROPP vs Vida vs Krimp: Temel Kapaklama Teknolojilerinin Karşılaştırılması

- Karbondioksitli İçecek Dolum Makineleri için Otomatik Kapaklama Sistemlerindeki Gelişmeler

- Kapatma Kalitesinden ödün vermeden Kapaklama Hızının Optimize Edilmesi