Reduce Labor Costs with Automated Precision

How Automatic Filling Machines Minimize Manual Labor Needs

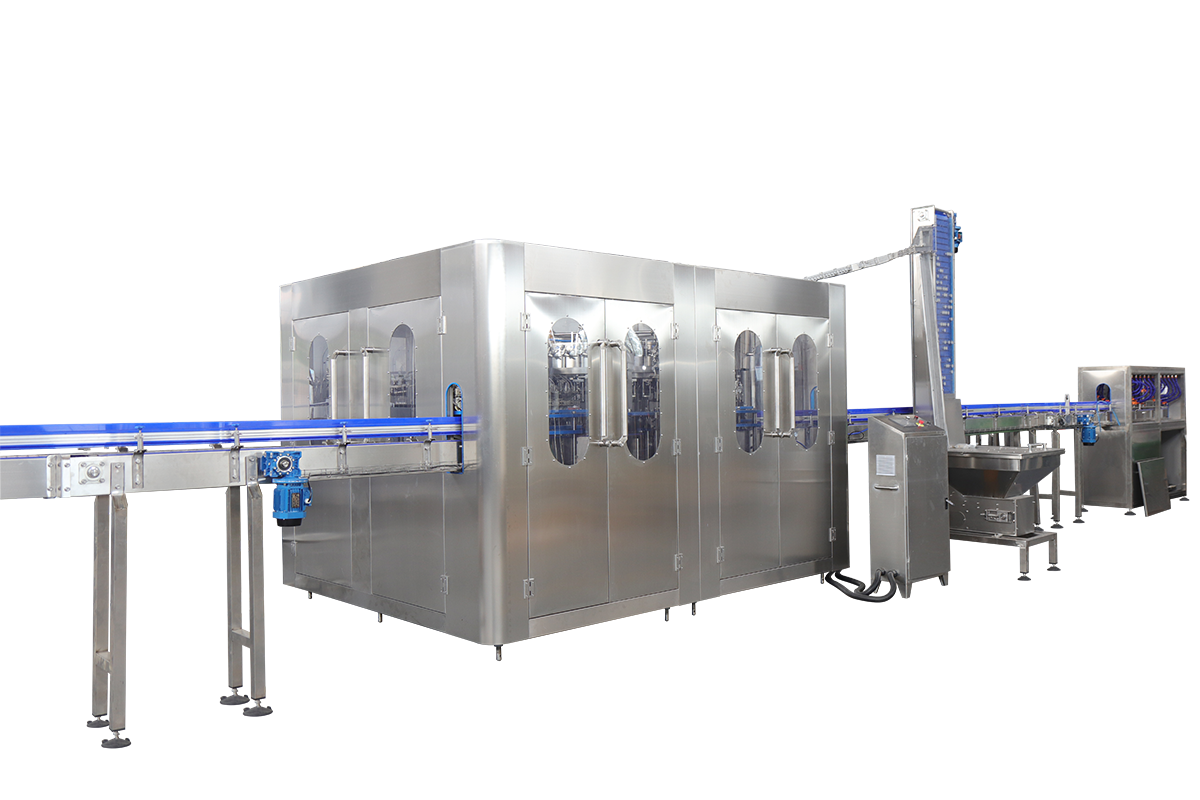

Filling machines that work automatically take care of all those boring, repetitive jobs like placing bottles just right, pouring the correct amount of liquid, and checking if everything looks good. These systems can handle between 200 to maybe even 500 containers each hour while getting measurements spot on down to fractions of a millimeter. They're way faster and more consistent than people working manually at these tasks. When companies automate things like making sure each container gets filled properly without spilling over, they end up needing far fewer workers watching over production lines. According to recent research from McKinsey & Company back in 2023, this cuts down staffing requirements for monitoring purposes by somewhere around two thirds to three quarters. What does this mean for factory workers? Instead of standing there adjusting every single bottle themselves, operators can watch several machines at once. Their role changes from constantly fixing problems caused by human error to managing operations overall, which makes the whole production process run smoother and more efficiently across the board.

Case Study: 40% Reduction in Labor Costs at a Mid-Sized Beverage Producer

One mid sized beverage company saved around half a million dollars each year on labor costs once they installed their new automated filling system. They had been running 12 separate manual stations back then, with three workers at each station, but now everything runs on a single automated line staffed by only two techs. The error rate plummeted too, going down from nearly 4% to just 0.3%, and production output went up by almost a quarter. Looking at what happened here isn't so different from what's happening across manufacturing right now. Most companies that bring in automation see their labor expenses drop somewhere between 15-25%, depending on how much they automate and what kind of operations they run.

Redeploying Staff to Higher-Value Operational Roles

Workers previously assigned to manual filling are now transitioning into more strategic roles, including:

- Machine maintenance and calibration

- Production data analysis

- Process optimization

A 2023 automation study found that 68% of manufacturers improved workforce productivity through this reallocation. Employees focus on initiatives like strategic quality control rather than repetitive tasks prone to fatigue-induced errors, enhancing both job satisfaction and operational performance.

Long-Term Savings from Lower Overtime and Reduced Turnover

Automated systems maintain consistent output around the clock, reducing reliance on overtime. Manufacturers report significant improvements across key metrics:

| Metric | Manual Process | Automated System |

|---|---|---|

| Annual overtime hours | 1,200 | 240 |

| Employee turnover rate | 34% | 11% |

| Recruitment/training costs | $18k/month | $4k/month |

Reduced physical strain from automated workflows decreases turnover by 63% in packaged goods sectors, preserving institutional knowledge and cutting recurring hiring and training expenses.

Cut Material Waste Through Consistent, Accurate Dosing

Precision Filling Eliminates Overfills, Spills, and Product Overflow

Automatic filling machines today can measure doses within about half a percent accuracy, which cuts down on all sorts of waste problems that come from overfilling, spilling, or uneven dispensing. A recent study from PMMI in 2023 showed that companies making food products saved around 30% less material each year when they switched from manual processes to these automated systems. The machines have some pretty clever features too, such as sensors that check weight continuously and nozzles that clean themselves automatically. These help maintain consistent volume measurements even when dealing with thick liquids or tricky powders that don't flow smoothly. Take pharmaceutical manufacturing for example where special inline systems mix powders right into liquid formulations. This approach alone has been shown to cut down wasted ingredients by approximately 18%, according to industry data.

Data-Backed Results: Up to 30% Annual Reduction in Material Waste

Looking at data across 142 different manufacturing plants, it turns out automatic filling machines actually save around $27,500 per production line every year when it comes to raw materials according to McKinsey's 2024 report. A real world example comes from one dairy company that installed IoT sensors on their filling equipment. Within just 12 months they managed to cut down creamer waste by about 34% simply because they could better control how much was being dispensed based on viscosity levels. There's another benefit too these automated systems help prevent what's called "giveaway" which basically means adding extra product to make sure nothing gets shortchanged. This practice ends up costing American manufacturers approximately $740,000 annually as noted in Ponemon Institute research from last year.

Maintaining Compliance and Brand Trust With Consistent Fill Levels

Manufacturers who switch to automated dosing systems tend to get about 23 percent fewer warnings from regulators such as the FDA. Why? Because these machines maintain fill tolerances that are roughly five times better than what's possible with manual filling methods. When containers consistently hold around plus or minus 0.3 milliliters, customers simply don't complain about getting shortchanged on product quantity. And those complaints can really hurt a brand over time, affecting nearly half of all companies in the long run according to recent studies. The pharmaceutical industry has seen this firsthand too. Companies there are reporting close to 90% reductions in batch recalls caused by incorrect fill volumes. This not only keeps them compliant with strict regulations but also builds lasting trust among consumers who expect nothing less than perfection when it comes to their medications.

Boost Production Efficiency and Output Capacity

Faster cycle times and continuous operation without fatigue

Unlike human operators, automatic filling machines operate 24/7 without performance decline, completing cycles up to 40% faster than manual methods. This sustained output is especially valuable during peak demand periods or when fulfilling large retail orders, enabling manufacturers to scale production reliably.

Seamless integration with capping, labeling, and conveyor systems

Modern packaging lines integrate filling units with IoT-enabled capping systems and smart conveyors, creating synchronized workflows that reduce bottlenecks by 18–22% compared to standalone equipment. This seamless transition from filling to labeling minimizes manual handling delays and ensures smooth throughput.

Scaling production without proportional cost increases

With automatic filling technology, manufacturers can double output capacity while increasing operational costs by only 30–35%. As highlighted in the 2023 Packaging Automation Report, companies leveraging this scalability achieve 2.8X faster production growth than competitors relying on manual operations–making it ideal for businesses expanding into new markets.

IoT-enabled monitoring for real-time performance optimization

Embedded sensors monitor fill accuracy, machine health, and energy use, feeding real-time data to central dashboards. Predictive analytics forecast maintenance needs with 92% accuracy, reducing unplanned downtime by 60% and ensuring optimal material usage across shifts.

Improve Safety and Minimize Operational Downtime

Reduced Contamination and Workplace Accidents Through Automation

Automatic machines cut down on contamination risks because they remove the need for humans to touch products during the filling process, which is really important in food manufacturing and making medicines. These machines also help companies follow Good Manufacturing Practice standards better than before and there are definitely fewer spills when people aren't manually handling things all the time. The U.S. Bureau of Labor Statistics reported something interesting back in 2023 actually plants that use automated systems saw about 35 percent fewer injuries involving hands and arms. That makes sense since workers aren't doing those same repetitive movements right next to moving parts anymore.

Predictive Maintenance in Modern Automatic Filling Machines

Modern equipment now comes with smart vibration sensors connected to the internet along with pressure monitoring tools that spot when parts start wearing out before they fail completely. The move away from fixing things only when they break down to predicting problems ahead of time cuts unexpected stoppages by around half at companies that have implemented these technologies. By replacing components during regular scheduled maintenance instead of waiting for breakdowns, businesses not only save money on costly emergency fixes but also stay within the requirements set by ISO 13849 standards regarding machine safety and reliability across their operations.

Achieve Long-Term Savings and Strong ROI

Typical ROI for Automatic Filling Machines Within 18–24 Months

The majority of companies get their money back on automatic filling machines somewhere between 18 to 24 months after purchase, thanks to all those savings they start making on labor costs, materials waste, and simply getting more product out the door faster. According to industry data from last year, around three out of four businesses hit their break even point within this timeframe, while bigger operations with lots of volume tend to see their investments pay off even quicker. Take for instance a mid sized food processor we worked with recently. After installing automated fillers, they cut down the time operators spent at the machines by almost two thirds. That translated into roughly $326k saved each year on wages alone, which meant they paid off the cost of the new equipment in just over a year and a half.

Five-Year Projection: Maintenance vs. Cumulative Operational Savings

While annual maintenance averages 12–15% of initial machine costs, operational savings grow substantially over time:

| Cost Factor | Year 1 | Year 3 | Year 5 |

|---|---|---|---|

| Labor Savings | $180k | $540k | $900k |

| Material Waste Reduction | $45k | $135k | $225k |

| Maintenance Costs | $28k | $84k | $140k |

| Net Savings | $197k | $591k | $985k |

A 2024 lifecycle analysis confirmed that cumulative savings exceed maintenance expenses by 340% within five years, even after accounting for part replacements and software updates.

Overcoming the Initial Cost Barrier With Long-Term Value

Equipment leases with rates around 4 to 6 percent APR plus government perks like those 30% tax credits available in certain manufacturing areas really cut down on initial expenses. A lot of factories take their savings from the first year and plow them back into buying more automation gear, which creates this kind of snowball effect where improvements fund themselves over time. Take a look at the math too one manual workstation usually costs about what covers 80% of an automated setup. Most plants find they can bridge that remaining cost within just 18 months thanks to all those small but steady efficiency boosts day after day.

FAQ

What are the main benefits of using automatic filling machines?

Automatic filling machines significantly reduce labor costs, minimize material waste, and improve production efficiency. They also enhance worker safety and provide consistent fill levels, which helps in maintaining compliance and building brand trust.

How do automatic filling machines impact labor costs?

These machines automate repetitive tasks, reducing the need for manual labor. As a result, staffing requirements for monitoring are reduced, and costs associated with overtime, recruitment, and training are lowered.

Can automatic filling machines help in reducing material waste?

Yes, automatic filling machines provide precise dosing, which minimizes overfills, spills, and product overflow, leading to a significant reduction in material waste.

What is the typical ROI period for automatic filling machines?

Most companies see a return on investment for automatic filling machines within 18 to 24 months due to savings in labor, reduced material waste, and increased efficiency in production.

How do automatic filling machines enhance workplace safety?

By automating processes and reducing the need for manual handling, these machines lower the risk of workplace accidents and contamination, contributing to a safer work environment.

Table of Contents

- Reduce Labor Costs with Automated Precision

- Cut Material Waste Through Consistent, Accurate Dosing

- Boost Production Efficiency and Output Capacity

- Improve Safety and Minimize Operational Downtime

- Achieve Long-Term Savings and Strong ROI

-

FAQ

- What are the main benefits of using automatic filling machines?

- How do automatic filling machines impact labor costs?

- Can automatic filling machines help in reducing material waste?

- What is the typical ROI period for automatic filling machines?

- How do automatic filling machines enhance workplace safety?