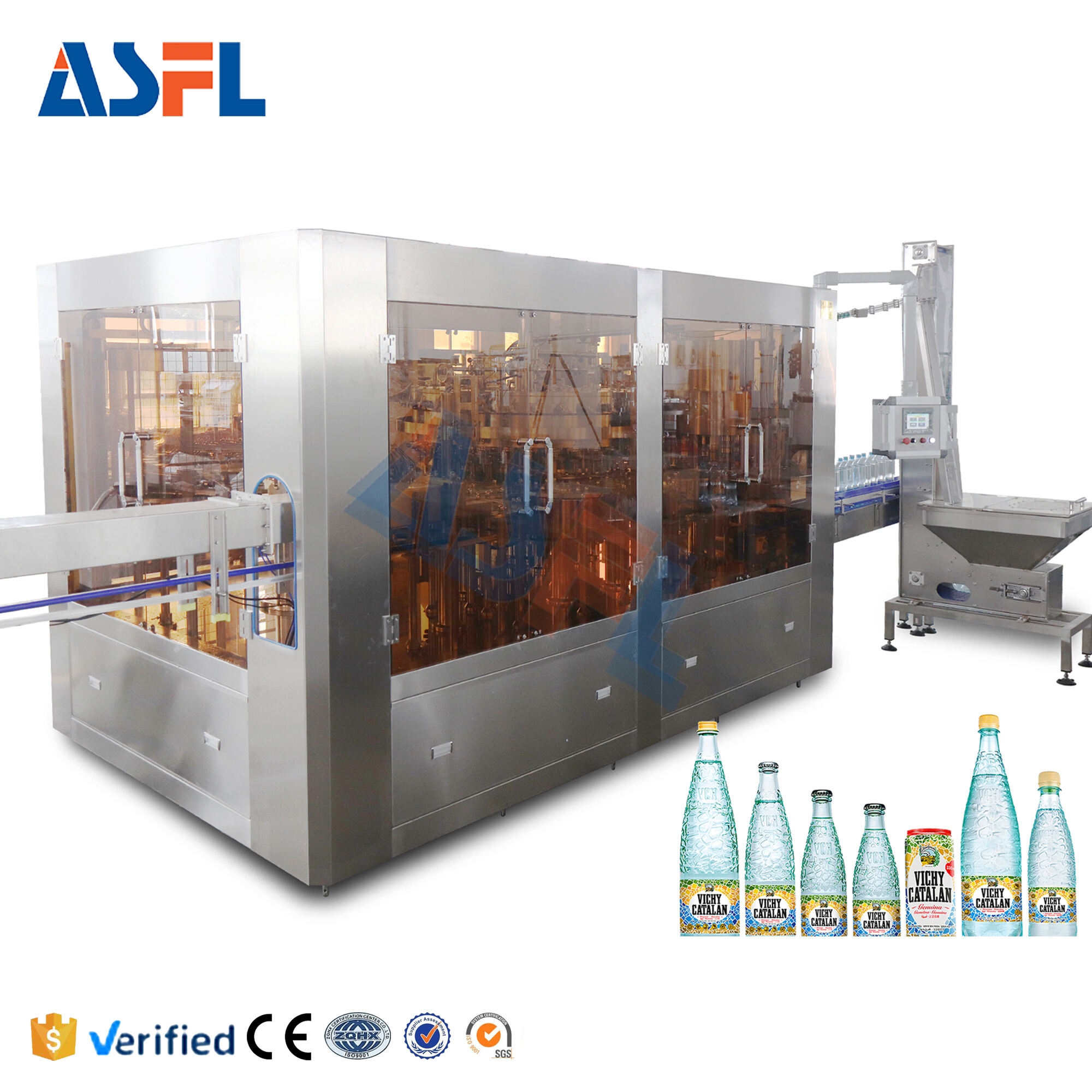

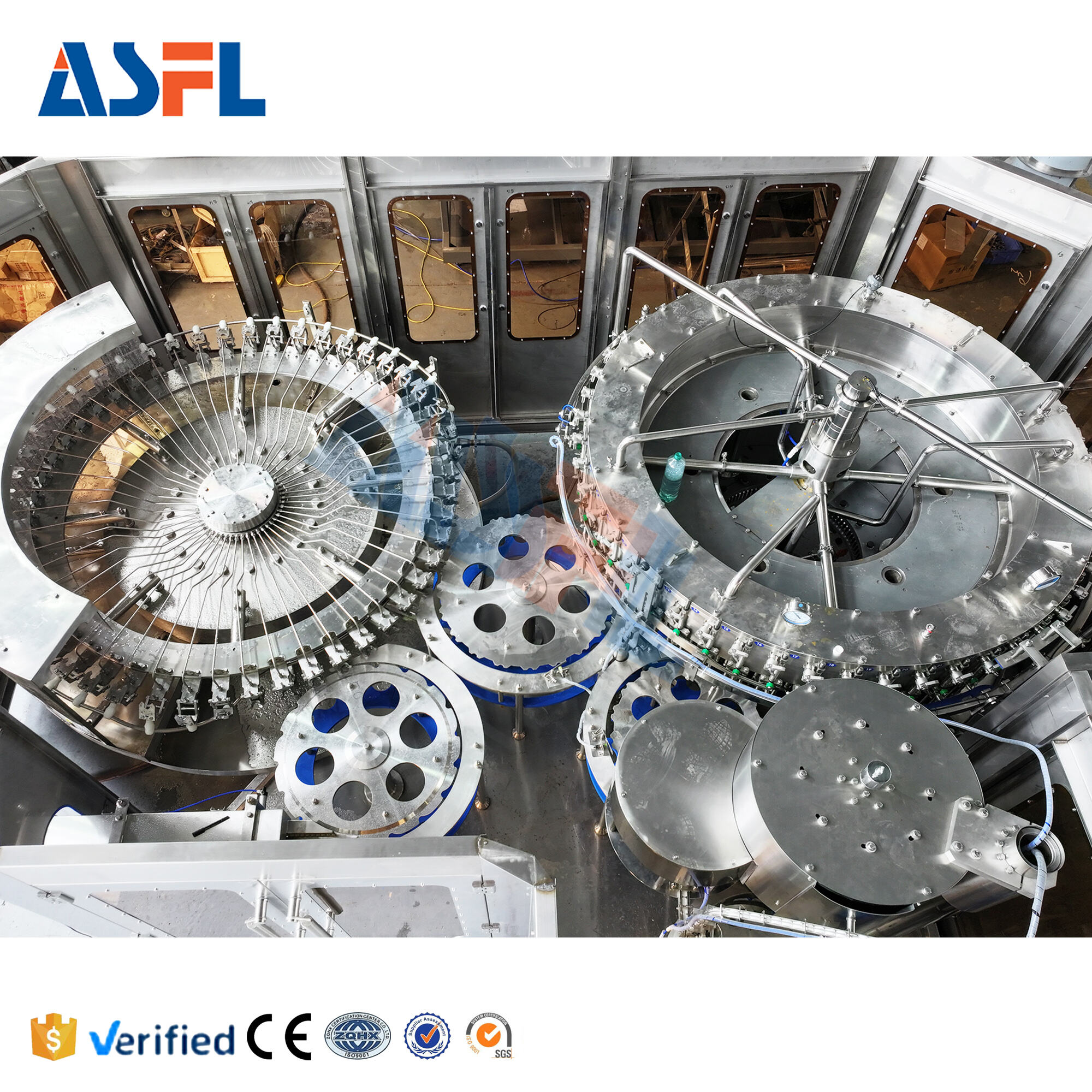

The High-Precision Carbonated Drink Filling Machine from Ace-Filling is engineered for excellence in fill volume accuracy, achieving tolerances as tight as ±0.5% of set volume. This exceptional precision is critical for brand owners to ensure regulatory compliance, avoid product giveaway (which represents significant financial loss at high volumes), and maintain consumer trust by delivering the exact advertised volume in every container. This accuracy is achieved through several advanced features: digitally controlled, servo-driven filling pistons or flow meters that provide unparalleled control over the liquid flow rate; highly sensitive pressure transducers that maintain perfect counter-pressure throughout the filling cycle to prevent foaming-induced inaccuracies; and self-adjusting valves that compensate for minor variations in bottle mouth dimensions. In a competitive market like premium craft soda or beer, where margin control and brand reputation are paramount, this high precision is a non-negotiable feature. The machine's control system continuously monitors and logs fill volumes for statistical process control (SPC), providing data for quality assurance and traceability. For applications where every milliliter counts, we invite you to contact us to discuss the high-precision capabilities of our fillers and request performance data sheets.