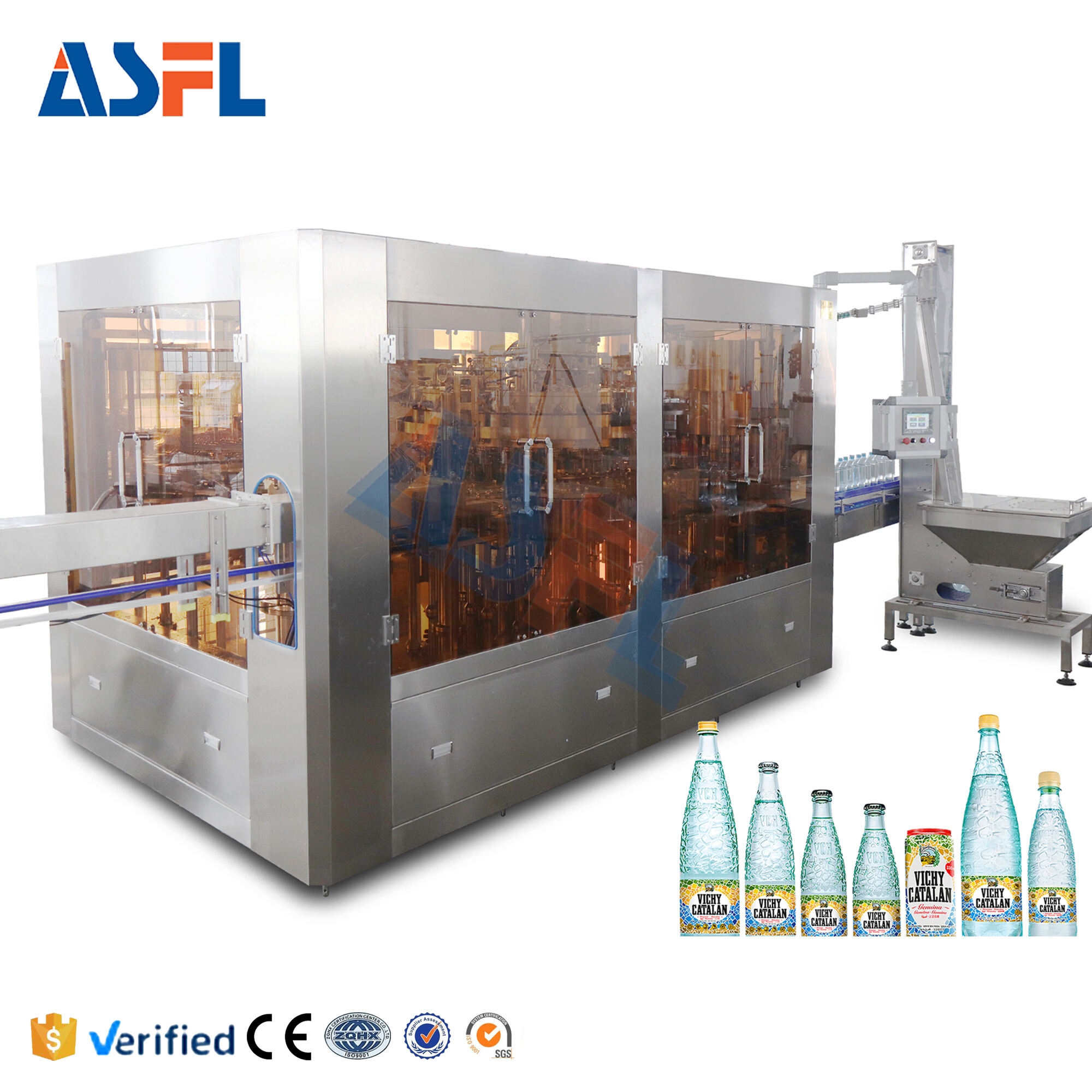

An Ace-Filling Carbonated Drink Filling Line is a complete turnkey solution that transforms raw ingredients into finished, market-ready products. This integrated system encompasses far more than just a filler; it is a synchronized series of machines working in perfect harmony. A standard line configuration includes: a water treatment system (e.g., reverse osmosis, deaeration), a syrup blending and dosing system, a carbonator for precise CO2 injection, a product cooler to maintain optimal filling temperature, an empty bottle unscrambler or depalletizer, an air cleaner or rinser to sanitize bottles, the core isobaric carbonated drink filling machine, a cap sterilizer (often using UV light), an automatic capping machine, a labeling machine, a date coder, a shrink wrapper for multi-packs, and a case packer and palletizer for final distribution. The entire line is governed by a centralized programmable logic controller (PLC) that synchronizes all components, ensuring smooth material flow, maximizing Overall Line Efficiency (OLE), and providing real-time production data monitoring. For a new beverage factory investment, we provide comprehensive services including process consulting, plant layout design, installation, commissioning, and operator training. To discuss configuring a complete carbonated drink filling line for your specific product and output goals, please contact our project engineering team for a consultation.