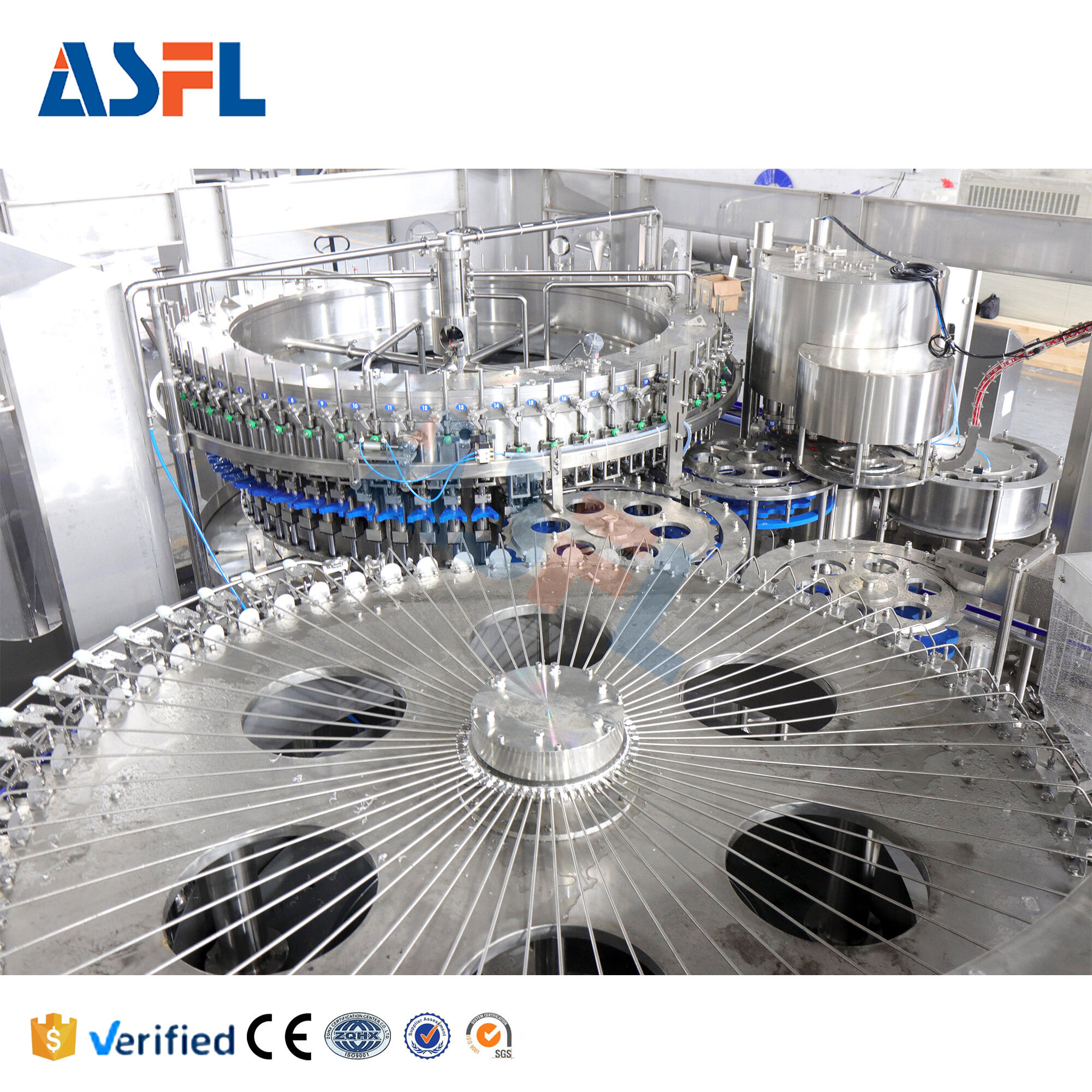

A beverage filling machine is a precision-engineered device designed to dispense a specific volume of liquid into containers such as bottles, cans, or jars. It is the critical component in any beverage production operation, directly impacting product quality, profitability, and operational efficiency. These machines utilize various filling principles based on the product's characteristics. Gravity fillers are used for still, non-foaming liquids like water and juices, where liquid flows from an elevated tank into bottles. Pressure fillers are essential for carbonated beverages like soda and beer, using counter-pressure to prevent CO2 loss during filling. Piston fillers are ideal for viscous products with pulps or concentrates. Key selection criteria include required output speed (bottles per hour), level of automation (semi-auto vs. fully auto), container type and size, and the product's properties (viscosity, carbonation, particulates). Ace-Filling, with over 20 years of experience, manufactures a comprehensive range of high-quality beverage filling machines constructed from food-grade stainless steel. They are designed for durability, easy maintenance, and hygiene, often featuring CIP (Clean-in-Place) systems. The company provides expert consultation to help clients select the perfect filler for their application, ensuring optimal performance and a strong return on investment.