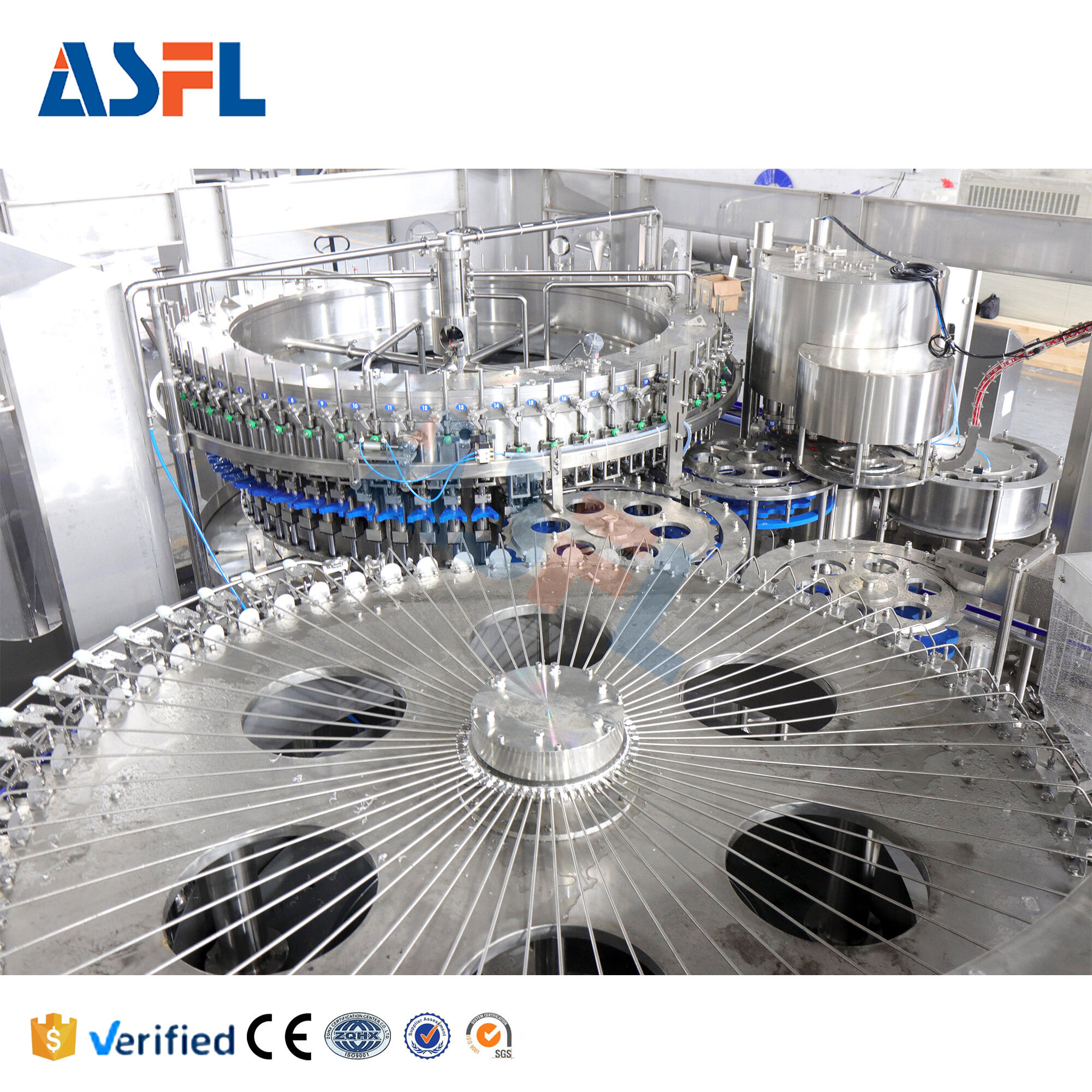

A beverage filling machine for carbonated drinks is a highly specialized piece of equipment engineered to handle the unique challenges posed by liquids containing dissolved carbon dioxide (CO2). The core technology employed is isobaric, or counter-pressure, filling. This process is meticulously designed to prevent the CO2 from breaking out of solution, which would cause excessive foaming, inaccurate fills, and product loss. The filling cycle involves several precise stages: First, the empty bottle is pressurized with CO2 or air to a pressure nearly identical to that in the product's holding tank. Once pressures are equalized, the product valve opens, and the liquid flows gently into the bottle without foaming because there is no pressure differential to drive out the gas. The liquid level is controlled by a volumetric measure or by a tube that signals the valve to close once the desired volume is reached. Finally, the pressure in the bottle's headspace is slowly released (de-gassed) before the bottle is released from the filling valve. Ace-Filling's carbonated drink fillers are constructed with precision machined valves to maintain these delicate pressures, and are often made from durable materials to withstand the corrosive nature of carbonated beverages. These machines are integral to the production of sodas, sparkling waters, beers, and champagnes, ensuring that every bottle is filled to the exact volume with the correct level of carbonation, preserving the drink's intended taste, mouthfeel, and effervescence.