CO2 Pressurization and Solubility: Foundations of Carbonation

Principles of Gas Solubility Under Pressure in Carbonated Drink Filling Machines

The process of making fizzy drinks depends heavily on something called Henry's Law. Basically, what this law tells us is that when pressure goes up, gases tend to dissolve better in liquids. That's why today's soda bottling equipment works the way it does. These machines typically crank up the pressure inside containers to around 2 to 2.5 bar while they're being filled. What happens next is pretty interesting. At these pressures, carbon dioxide dissolves into the beverage at about 5 to 7 grams per liter. This creates that nice steady fizz we all know and love in our soft drinks. Without getting too technical, this balance between pressure and gas dissolution makes sure every bottle has just the right amount of bubbles.

Impact of Temperature and Pressure on CO₂ Solubility in Beverages

Temperature significantly influences CO₂ solubility—each 10°C rise reduces gas retention by approximately 15%, increasing risks of flatness and foaming. To maximize carbonation stability, industry-standard systems maintain liquid temperatures between 2°C and 4°C during filling:

| Parameter | Optimal Range | Purpose |

|---|---|---|

| Liquid Temperature | 2°C — 4°C | Minimizes CO₂ volatility |

| System Pressure | 2.0 — 2.5 bar | Preserves dissolved CO₂ during bottling |

This thermal control is essential for maintaining solubility under operational pressures.

Pre-Pressurization and Counter-Pressure Techniques to Maintain Equilibrium

Modern filling equipment prevents carbon dioxide from escaping during container filling through something called counter-pressure tech. The process starts by pressurizing bottles with CO₂ so they match what's inside the filling system right before liquid goes in. This approach cuts down on turbulence problems by around two thirds compared to regular atmospheric filling methods, and it keeps about 30 percent less gas from leaking out according to Beverage Engineering folks back in 2023. Pair this with those programmable logic controllers for fine tuning, and manufacturers can maintain CO₂ levels within just 0.2 percent differences between batches. That kind of consistency makes all the difference for brands trying to deliver exactly the same taste experience every time someone opens a bottle.

Precision Filling Systems: Synchronizing Flow, Pressure, and Sealing

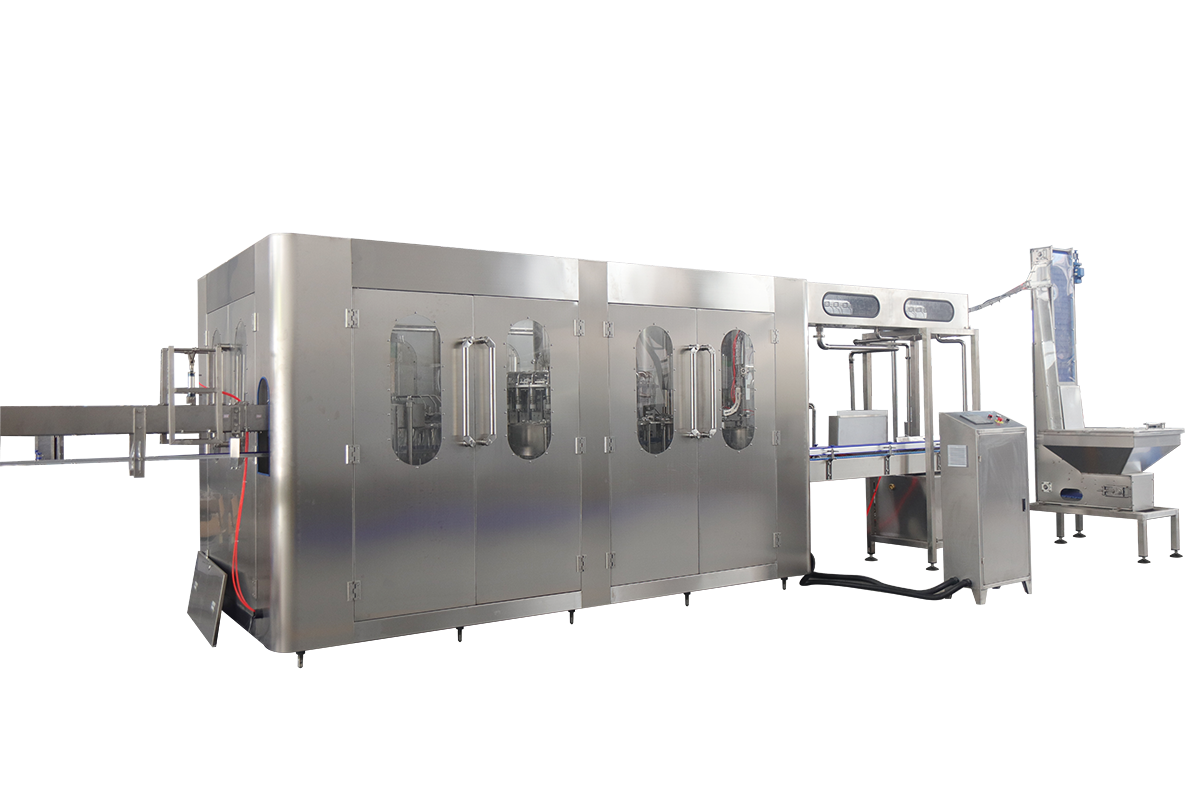

Modern carbonated drink filling machines preserve carbonation through precise coordination of fluid dynamics, pressure management, and sealing speed. By synchronizing these elements, they minimize turbulence and gas loss throughout the fill cycle.

Synchronization of Filling and Sealing to Lock in CO₂ Effectively

The time gap between when a bottle gets filled and when it gets capped matters a lot actually. If bottles stay uncapped too long, they start losing carbon dioxide pretty fast - somewhere around 2 to 5 percent every single second because of this thing called off-gassing. Modern production lines have gotten smarter though. They use these fancy servo motors for the capping mechanism that kicks in just about 0.3 seconds after the filling process finishes. What does this mean? Well, the cap seals onto the bottle almost instantly, keeping all that precious fizz inside where it belongs. Studies looking at how air pressure systems work together back up this approach, showing why speed really counts in maintaining product quality throughout manufacturing runs.

Real-Time Monitoring of CO₂ Pressure and Liquid Flow to Reduce Turbulence

Integrated sensors continuously monitor key parameters:

- Liquid velocity (optimal: 1.2—1.8 m/s)

- Headspace pressure (maintained at 3.2—3.8 bar)

- Temperature differentials (ΔT ≤ 1.5°C)

These inputs feed adaptive algorithms that adjust nozzle performance up to 120 times per second, reducing turbulent flow by 72% compared to mechanical controls (Beverage Production Journal, 2023).

Common Causes of CO₂ Loss During Bottling and How Modern Filling Machines Prevent Them

| Challenge | Conventional Systems | Advanced Solutions |

|---|---|---|

| Foam formation | 15-20% CO₂ loss | Anti-cavitation valves |

| Thermal shock | 8-12% carbonation drop | Pre-chilled container handling |

| Seal imperfections | 0.5-2% daily leakage | Laser-aligned capping torque control |

By integrating gas recovery systems and surface-tension-optimized filling paths, modern pressure-optimized filling architectures achieve 98.6% CO₂ retention across production runs.

Advanced Filling Valve Design for Optimal CO₂ Retention

Engineering Staged Filling Valves to Manage Pressure Gradients and Foam Control

Staged filling valves are engineered to manage pressure transitions gradually, minimizing CO₂ escape. These multi-phase systems begin with high-pressure CO₂ injection to suppress foam, then progressively reduce pressure as the liquid level rises. This method maintains a 15—20% tighter pressure gradient than single-stage designs, enhancing carbonation stability.

Key valve components include:

| Component | Function | CO₂ Retention Benefit |

|---|---|---|

| Isobaric control chamber | Matches beverage/bottle pressure | Prevents 92% of gas breakout* |

| Vent tube regulators | Release excess gas without liquid loss | Maintains 2.6—3.2 bar optimal headspace pressure |

| Laminar flow nozzles | Reduces liquid turbulence by 40% | Lowers foam formation risks |

*Based on 2023 beverage carbonation trials

CO₂ Purging and Pre-Pressurization of Containers Before Filling

Top manufacturers purge containers with CO₂ at 1.8x operational pressure prior to filling, displacing ambient air—particularly nitrogen, which competes with CO₂ for dissolution. This process improves final carbonation levels by 12% in PET bottles compared to non-purged counterparts.

The sequence includes:

- Vacuum removal of residual O₂ (≤0.5%)

- CO₂ injection at 3.5—4 bar for 0.8—1.2 seconds

- Pressure stabilization before liquid transfer

Industry studies confirm this “gas cushion” approach reduces CO₂ loss by 18—22% across various container types. Advanced systems now auto-adjust purge settings based on real-time volume detection.

Real-Time Monitoring and Automation in Carbonated Drink Filling Machines

Sensor Integration for Continuous CO₂ and Flow Dynamics Tracking

Today's filling lines come equipped with infrared CO2 sensors alongside ultrasonic flow meters that keep track of dissolved gas levels with around 0.05% accuracy and measure viscosity as it happens. These systems gather data at intervals of just 50 milliseconds, which helps maintain those high speed operations running at about 1200 bottles per minute without letting carbonation levels get out of whack either way. When pressure gets too far off track beyond plus or minus 0.2 bar, built-in pressure transducers kick in to make adjustments automatically. This keeps everything balanced during processing so there aren't any unexpected changes in product quality down the line.

Automated Feedback Loops for Adaptive Process Control

PLCs look at sensor readings and make real time changes to things like nozzle settings, how much CO2 gets injected, and conveyor belt speed. When the dissolved CO2 drops under 2.7 volumes which is what we consider good enough for proper carbonation levels, the system kicks in extra pressure really fast about 100 milliseconds actually. The whole automated process cuts down on human involvement by around 92 percent according to Food Engineering from last year. Plus it keeps liquid levels spot on throughout each batch with just half a millimeter variation either way.

Data-Driven Calibration to Optimize Machine Efficiency and Consistency

Modern machine learning approaches look at past performance data alongside factors such as air moisture levels and syrup temps to make operational improvements. The Zenith Filling facility saw real results when they implemented these smart systems back in 2024. Their unplanned equipment shutdowns dropped by almost 40%, while their yearly carbon emissions went down around 18%. What's really impressive is how these automated systems adjust valve timings and cleaning intervals automatically. On fast production lines, this leads to nearly perfect carbonation throughout the entire batch, with over 99% consistency between the very first and last bottles produced.

End-to-End Carbonation Integrity: From Formulation to Hermetic Sealing

Strategic CO₂ Over-Saturation to Offset Expected Losses During Filling

Manufacturers intentionally carbonate beverages 10—15% above target levels to compensate for expected losses during high-speed filling. This buffer accounts for gas escape during purging, interface turbulence, and thermal expansion. For example, a 5°C temperature fluctuation can decrease CO₂ solubility by 18% (Beverage Production Handbook, 2023), making over-saturation essential for batch consistency.

Use of Stabilizing Additives to Enhance Post-Fill Carbonation Longevity

Food-grade additives such as xanthan gum and calcium lactate improve bubble nucleation and slow CO₂ diffusion by forming microstructural networks in the liquid. These compounds extend carbonation stability during shelf-life temperature variations, reducing gas migration by up to 32% compared to untreated formulations.

Hermetic Sealing Technologies Ensuring Long-Term CO₂ Retention in Finished Products

Final carbonation integrity depends on reliable sealing. Modern machines incorporate laser-validated closure systems that achieve annual leak rates below 0.02%. Key features include:

- Pressure-activated polymer gaskets that conform to container flaws

- Multi-stage capping with real-time torque verification (±2% accuracy)

- Tamper-evident designs capable of sustaining 4.5—6 bar internal pressure

A 2021 study of 12,000 containers found heat-sealed aluminum lids retained 98.7% of initial CO₂ after six months—19% better than standard screw caps (Packaging Technology & Science). This precision sealing completes the end-to-end strategy for long-term carbonation integrity.

FAQ Section

What is the role of pressure in carbonation?

Pressure helps dissolve carbon dioxide in beverages, creating carbonation. Henry's Law explains that increased pressure leads to better gas solubility in liquids.

How does temperature affect carbonation?

Higher temperatures decrease CO₂ solubility, risking flat drinks. Maintaining cooler temperatures during bottling helps retain carbonation.

What methods prevent CO₂ loss during bottling?

Techniques like counter-pressure filling, rapid capping, and temperature control help prevent CO₂ loss and maintain carbonation quality.

Table of Contents

- CO2 Pressurization and Solubility: Foundations of Carbonation

- Precision Filling Systems: Synchronizing Flow, Pressure, and Sealing

- Advanced Filling Valve Design for Optimal CO₂ Retention

- Real-Time Monitoring and Automation in Carbonated Drink Filling Machines

- End-to-End Carbonation Integrity: From Formulation to Hermetic Sealing

- FAQ Section