How Hot Fill Technology Works in Juice Filling Machines

Definition and Process of Hot Filling Technology

The hot fill method keeps juices fresh by heating them up to around 88 to 96 degrees Celsius (that's about 190 to 205 Fahrenheit) right before they go into containers. The heat from the juice itself does double duty here, killing off bacteria in both the drink and whatever packaging it ends up in. No need for those artificial preservatives anymore, which means longer shelf life without compromising taste or quality. These days most commercial juice lines have really advanced equipment that can keep temperatures just right during processing. Manufacturers talk about something called thermal stabilization when explaining how they manage to get consistent results batch after batch, making sure harmful microbes don't survive the treatment.

Sterilization Mechanism: How Heat Kills Microbes in Product and Container

This method gets rid of harmful bacteria and other bad stuff by breaking down the proteins and enzymes inside them when they're exposed to heat for a long time. Keeping things hotter than 85 degrees Celsius (which is around 185 Fahrenheit) for somewhere between one to three minutes really matters because at that point most of the nasty stuff in acidic drinks gets neutralized. When the heated juice goes into the container, it actually cleans every part of the inside surface including those tricky little threads on the cap just by touching them directly with the hot liquid.

Temperature Requirements and Critical Control Points in the Process

| Parameter | Range | Purpose |

|---|---|---|

| Heating Phase | 88—96°C (190—205°F) | Pathogen elimination |

| Holding Time | 15—180 seconds | Ensure microbial lethality |

| Filling Temperature | ≤85°C (185°F) | Container sterilization |

| Cooling Rate | ≤1°C/minute | Prevent container deformation |

Studies show that exceeding 90°C (194°F) for at least 15 seconds meets FDA requirements for commercial sterility in acidic beverages.

Step-by-Step Workflow: Heating, Filling, Sealing, and Cooling

- Heating: Juice is rapidly heated to target temperatures using plate heat exchangers

- Filling: Machines inject liquid above 85°C into pre-warmed containers within 2—5 seconds

- Sealing: Caps are applied immediately under sterile conditions to prevent recontamination

- Controlled Cooling: Gradual cooling to 35—40°C (95—104°F) creates a vacuum seal and prevents container collapse

This sequence enables a 6—12 month shelf life without preservatives. While some nutrient loss occurs, modern systems use optimized cooling protocols to preserve flavor and nutritional integrity.

How pH and Acidity Define Hot Fill Applications for Juice Filling Machines

Why Low pH (Acidic) Juices Are Ideal for Hot Fill Processing

Acidic juices with pH levels under 4.5 tend to resist microbial growth pretty well, which is why they work so great for hot filling processes. Heating these juices between about 85 to 95 degrees Celsius creates this interesting situation where both heat and acidity start breaking down enzymes in spoilage microbes such as Alicyclobacillus species and various yeasts. What makes this approach special is that it lets food manufacturers reach sterile conditions without needing any added chemicals. Take orange juice for instance, recent research from 2023 showed samples with around pH 3.5 stayed safe and didn't spoil even after sitting on shelves for an entire year. The fact that acidic environments have built-in antimicrobial effects means processors can actually cut down on how long they need to expose products to heat. Studies indicate this saves roughly 15 to 20 percent of heating time when compared to drinks with more neutral pH levels.

Common Acidic Beverages Processed With Hot Fill: Juices, Nectars, Flavored Waters

Hot fill is widely used for:

- Fruit juices (apple, cranberry, pineapple)

- Nectars (peach, mango, apricot blends with 25—50% fruit content)

- Flavored waters (citrus-infused, berry-accented variants at pH 3.8—4.2)

These products represent 78% of global hot-filled beverage production due to their microbial stability during cooling. Tomato-based drinks (pH ~4.3), while borderline, can be processed safely with tight temperature control (±1°C) to avoid under-processing risks.

Shelf Life Extension and Natural Preservation Benefits

Extending shelf life without preservatives through thermal stabilization

When juice gets heated up to around 90-95 degrees Celsius (that's about 194-203 Fahrenheit) right before it goes into containers, the hot fill process kills off those pesky spoilage bugs like Alicyclobacillus and yeast strains. What this means is that acidic fruit drinks can stay fresh on store shelves for anywhere between 12 to 18 months without needing all sorts of chemical preservatives. A recent report from Food Preservation folks in 2024 shows that almost seven out of ten beverage makers have switched over to this approach for making products with cleaner ingredient lists. The trend really took off in the organic market and among companies selling health-focused juices where consumers care deeply about what's actually in their bottles.

Balancing preservation benefits with potential nutrient and flavor loss

Exposing foods to temperatures above 85 degrees Celsius for too long will start breaking down those sensitive vitamins we all hear so much about, like vitamin C and B6. The degradation rate is somewhere around 15 to 20 percent when kept at these high temps for extended periods. But here's the catch: roughly 40 percent of our food gets wasted because it doesn't last long enough. That makes sense why controlled heating processes have become such a go-to solution for many producers. Take modern juice filling equipment for instance. These machines actually modulate temperatures very precisely during processing. As a result, they manage to keep about 92 to 95 percent of the original nutritional value intact while still killing off harmful microbes. Pretty impressive balance if you ask me.

Cooling methods post-fill to preserve taste, nutrition, and safety

Cooling rapidly to 38°C (100°F) within 20 minutes after sealing prevents overcooking and helps:

- Preserve crisp flavor by halting thermal degradation and caramelization

- Minimize vitamin oxidation via controlled atmosphere cooling tunnels

- Maintain container integrity through balanced pressure equalization

This staged cooling ensures products meet both regulatory standards and consumer expectations for taste and quality.

Container Materials and Packaging Requirements for Hot Fill

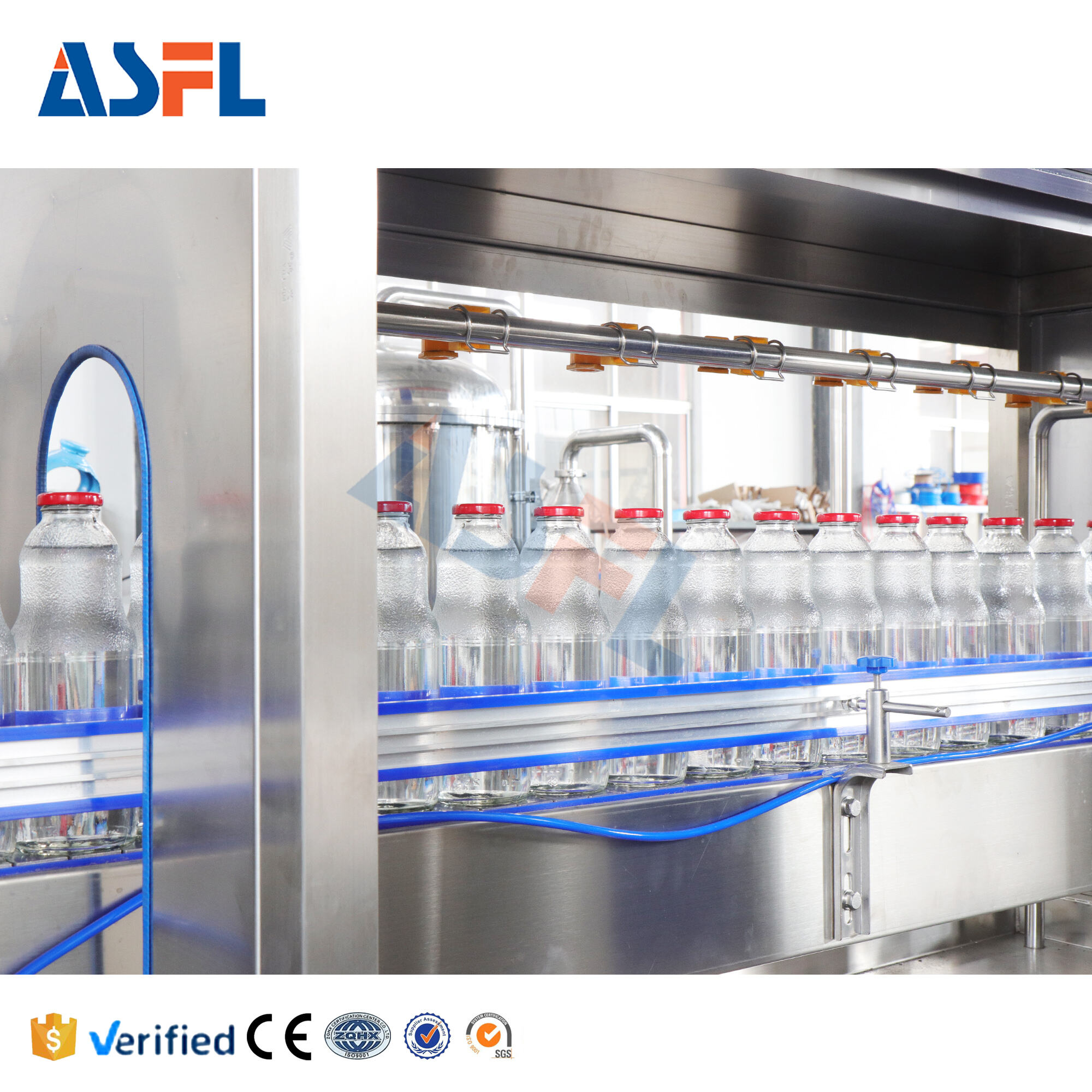

Suitable Packaging Materials: Glass, Heat-Resistant PET, and Caps

When it comes to hot fill applications, containers need to handle temperatures reaching around 90 degrees Celsius without bending or breaking. While glass containers are pretty much immune to temperature changes and won't let anything seep through, most manufacturers have switched to heat resistant PET plastic these days. The plastic stuff works better on those super fast production lines and doesn't break as easily when dropped. Both glass and PET plastics pass all the required food safety tests, though nobody talks about the caps nearly enough. Those little lids actually matter a lot because they need to create tight seals that hold up against heat. Packaging Digest reported last year that about one out of every four hot fill problems happens because the cap didn't seal properly. That's why companies spend so much time testing different closure designs.

Container Sterilization During Filling and Structural Integrity Under Heat

When hot juice comes into contact with the inside of containers, it actually acts as a sterilizing agent, killing off harmful bacteria such as E. coli and Salmonella. But there's another challenge manufacturers face. As the product cools down after pasteurization, vacuum forms inside the package which can cause problems. That's why many PET bottles are designed with reinforced walls or special ribs along their sides to prevent them from collapsing. Glass containers don't have these structural concerns, though they do bring their own set of issues related to weight and breakage risks. According to industry reports, heat resistant PET materials manage to reduce microbes by around 95% while only showing about 2% deformation when exposed to high temperatures. These characteristics make PET particularly well suited for big scale juice production lines where consistency and reliability matter most.

Advantages and Trade-offs of Hot Fill Technology in Modern Juice Production

Cost efficiency, scalability, and preservative-free production benefits

The hot fill process combines sterilization and actual filling in a single operation, which cuts down on equipment requirements by roughly 20 to 30 percent when compared to having separate machines for each task. Manufacturers can handle anywhere between 5,000 and half a million items per day using this method, and what's really nice is that it creates products without preservatives that still last around six to twelve months on store shelves. Because of these operational efficiencies, many high end organic product lines have adopted the technology, but it also works great for companies trying to reach consumers who want cleaner ingredient lists without sacrificing shelf stability or production volume capabilities.

Energy consumption challenges and industry considerations

Keeping temperatures just right during heating around 85 to 90 degrees Celsius plus the need for fast cooling eats up a lot of energy. When it comes to packaging that can withstand heat, companies see their material expenses go up anywhere from 15% to 25%. Big factories sometimes install closed loop thermal recovery systems which do cut down on waste, but for smaller operations the upfront investment is simply too steep to justify. Still there are real improvements happening in how we design equipment to be more energy efficient. Manufacturers working on hot fill processes have made progress lately, though getting widespread adoption remains a challenge due to those initial cost barriers.

FAQ

What is hot fill technology?

Hot fill technology is a method used to preserve juices by heating them up to kill bacteria without the use of preservatives, thereby extending their shelf life.

Why is acidity important in hot fill processing?

The acidity in juices helps in resisting microbial growth, making them ideal for hot fill processing which allows manufacturers to reach sterile conditions without added chemicals.

What types of containers are suitable for hot fill processing?

Glass containers and heat-resistant PET plastics are suitable for hot fill processing as they can handle high temperatures without bending or breaking.

What are the energy consumption challenges related to hot fill technology?

The requirement to maintain high temperatures during heating and the need for fast cooling can increase energy consumption and material costs, posing challenges for manufacturers.

How does hot fill technology extend the shelf life of juices?

By heating juices to high temperatures before filling, hot fill technology effectively kills spoilage microbes, allowing acidic fruit drinks to remain fresh for 12 to 18 months without preservatives.

Table of Contents

- How Hot Fill Technology Works in Juice Filling Machines

- How pH and Acidity Define Hot Fill Applications for Juice Filling Machines

- Shelf Life Extension and Natural Preservation Benefits

- Container Materials and Packaging Requirements for Hot Fill

- Advantages and Trade-offs of Hot Fill Technology in Modern Juice Production

- FAQ