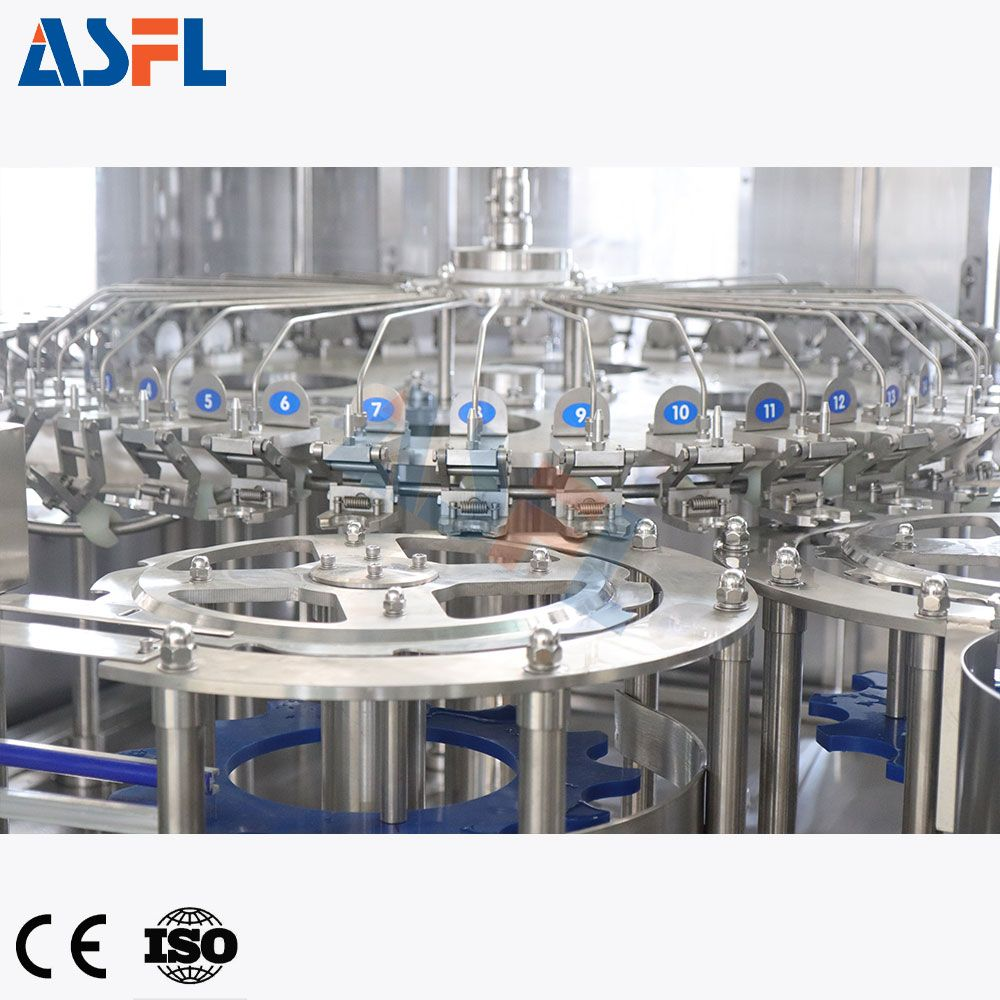

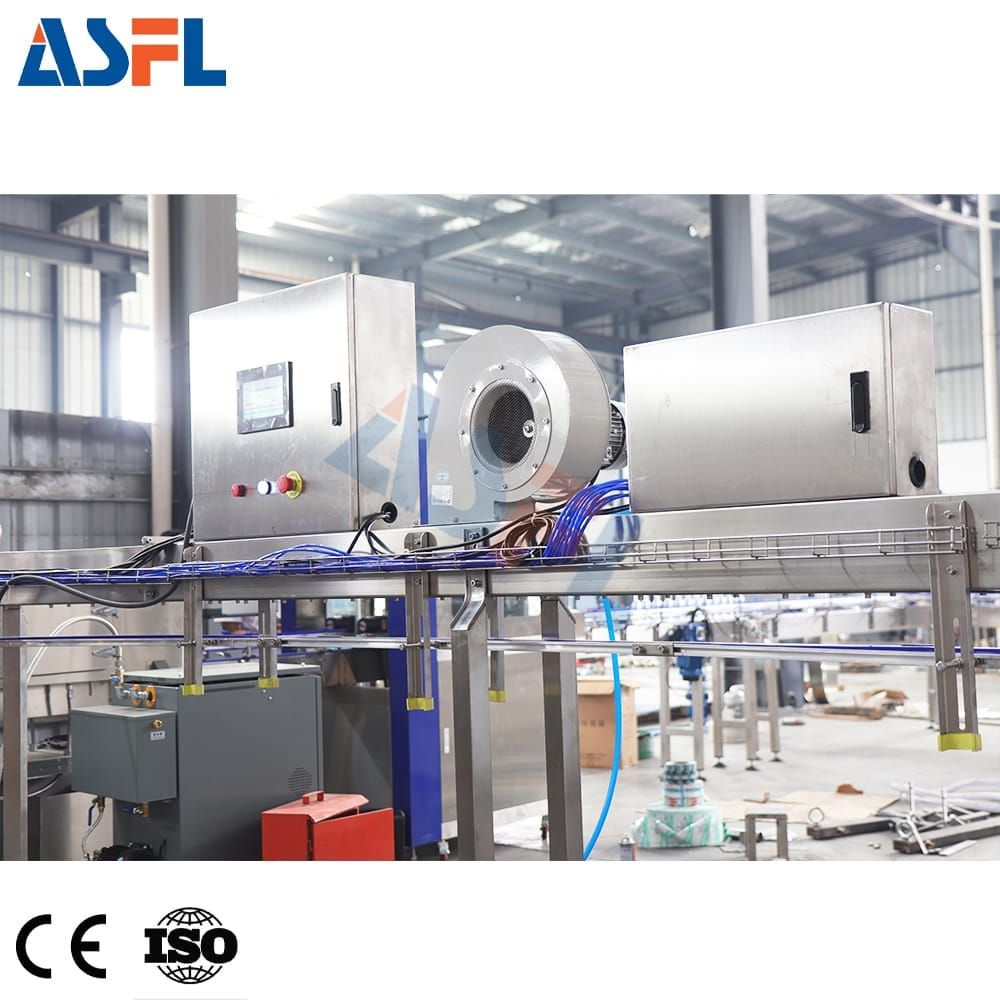

The beer can filling machine by Ace-Filling (Suzhou) Packaging Machinery Co., Ltd. is a specialized solution designed for the precise and hygienic filling of beer into aluminum cans. This machine incorporates advanced filling technology that ensures accurate volume control and minimal product loss. It features an automated can feeding system, filling station, and seaming unit, providing a complete canning solution for beer producers. A notable application is in a craft brewery in the United States that adopted our beer can filling machine, achieving a significant increase in production capacity and improved product consistency. The machine's robust construction and user-friendly interface facilitate easy operation and maintenance. With our comprehensive after-sales service, customers receive ongoing support and maintenance. For pricing and customization options, please contact our sales representatives.