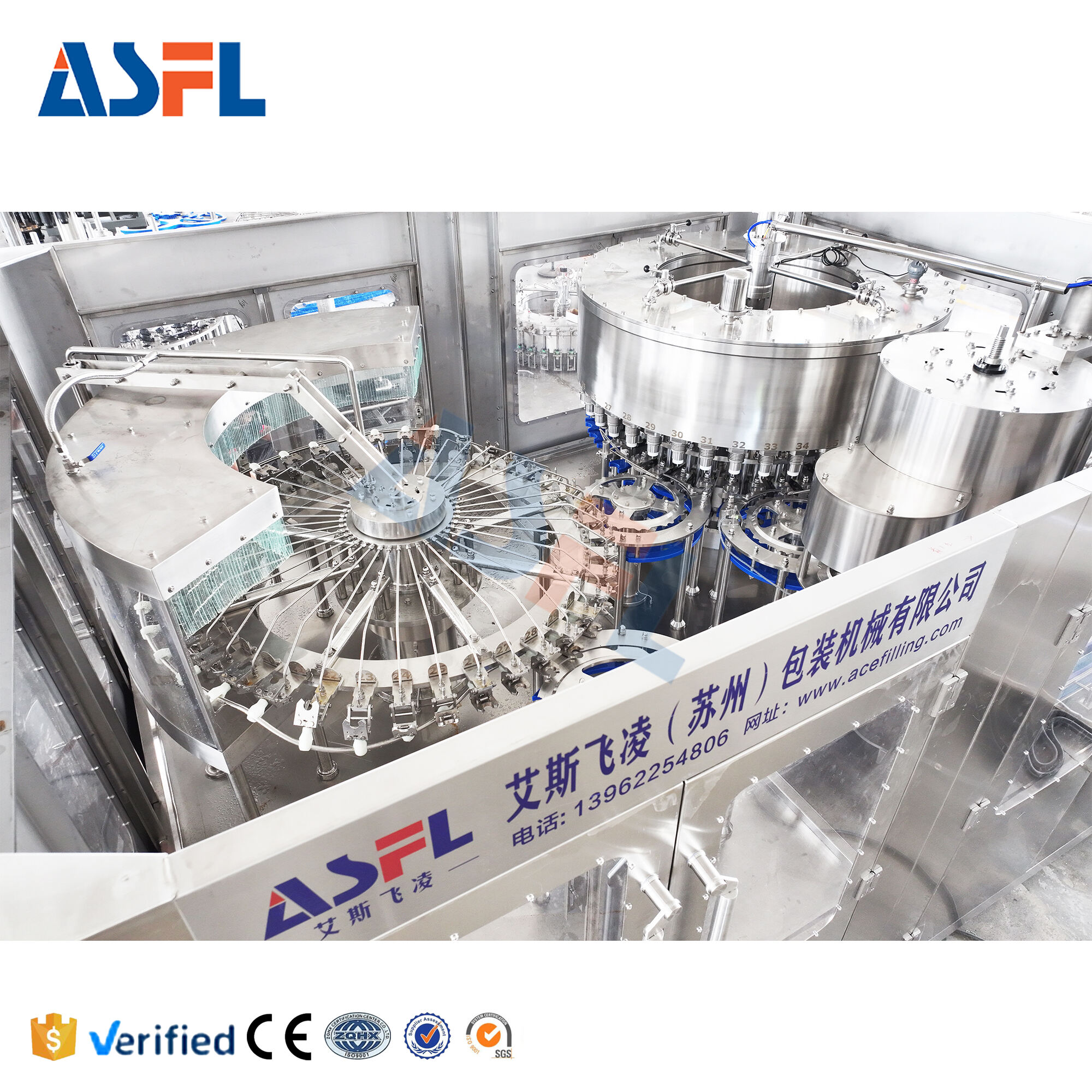

The PLC-Controlled Water Filling Machine from Ace-Filling utilizes a programmable logic controller as its central nervous system, providing robust, reliable, and precise automated control over the entire filling process. The PLC executes the machine's operational sequence, monitoring inputs from a network of sensors (e.g., bottle presence, tank level, pressure sensors) and controlling outputs to actuators (e.g., valves, motors, drives). Operators interact with the machine through a user-friendly Human-Machine Interface (HMI) touchscreen. This interface allows for easy setting of critical parameters like fill volume, production speed, and CIP cycles, and stores recipes for different products for instant recall. The system provides real-time monitoring of production metrics such as bottles filled, efficiency, and downtime reasons. Comprehensive fault detection alerts operators to issues like bottle jams or low cap supply, and the system can often perform automatic rejections. This level of control ensures consistent product quality, reduces operator error, simplifies troubleshooting, and provides valuable data for production analysis and traceability. For technical specifications and to discuss the control capabilities of our water filling machines, please contact our automation engineering team.