Project Overview

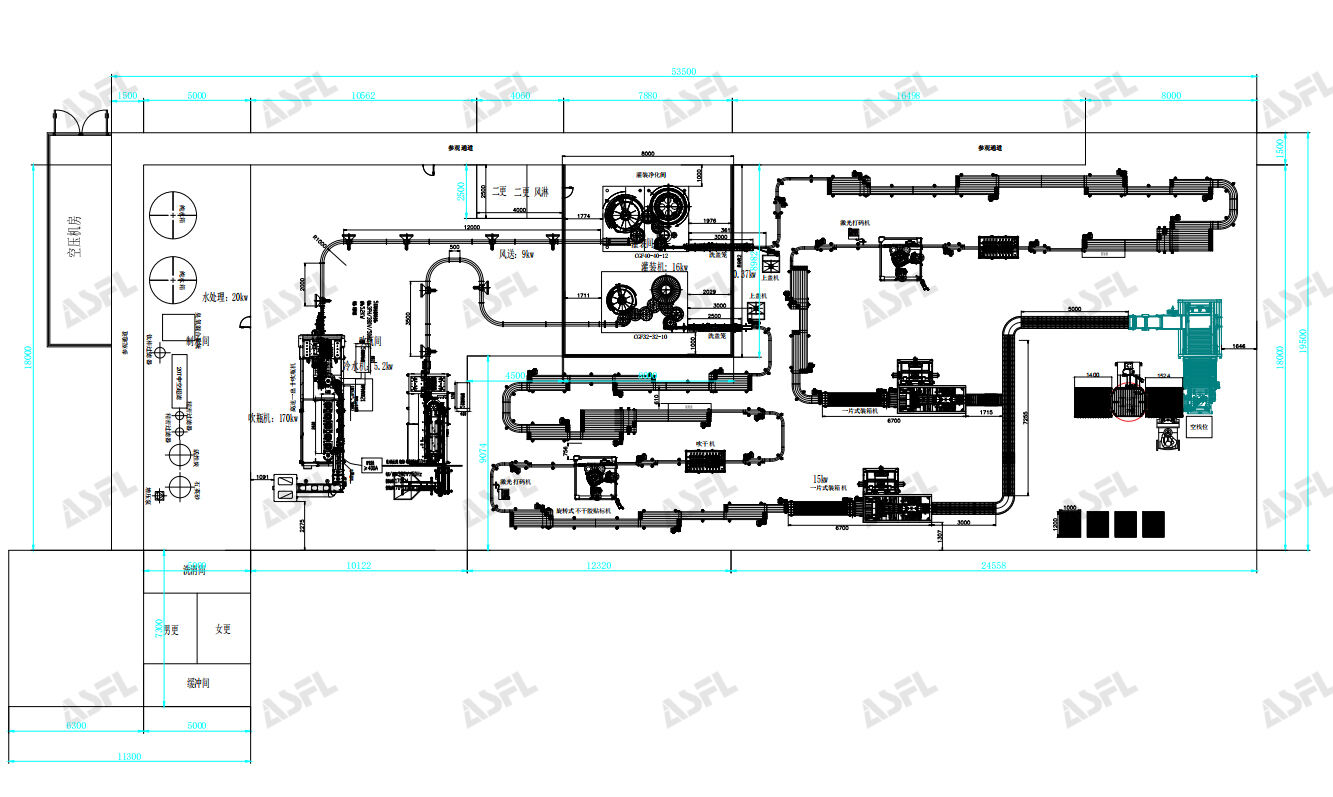

To meet the growing demand for bottled water in the plateau region, we delivered a fully automatic purified water production line with a capacity of 18,000 bottles per hour to our client in XiZang. Our team provided a complete turnkey solution covering factory layout design, equipment manufacturing, and on-site installation and commissioning. The entire line has now been successfully put into operation.

Capacity:18,000 BPH(500ml PET Bottle)

Application: Purified Water

Region:XiZang, China

Complete Line Configuration

| System Module | Description |

| Water Treatment System | Multi-stage filtration, reverse osmosis, and sterilization ensure safe and stable drinking water quality. |

| Blow Molding System | High-speed automatic blowing ensures stable bottle shapes and premium appearance. |

| Filling System | High-precision valves ensure hygienic and accurate filling. |

| Post-packaging System | Sleeve labeling and shrink wrapping provide efficient and neat packaging. |

| Automatic Palletizer | Automates stacking for easy storage and logistics. |

| Conveyor System | Intelligent line integration ensures smooth and efficient production flow. |

Installation & Commissioning

Our engineering team overcame the plateau’s challenging environment to complete the full installation and commissioning efficiently, ensuring smooth production start-up for the client.

Project Achievements

✅ Improved local production efficiency and product quality

✅ Strengthened the client’s market competitiveness in the plateau region

✅ Laid a solid foundation for future capacity expansion and product diversification

Watch the video below to see the full production line in action.

Hot News

Hot News2025-09-30

2025-08-28

2025-06-16

2024-08-02

2024-08-02

2024-07-23