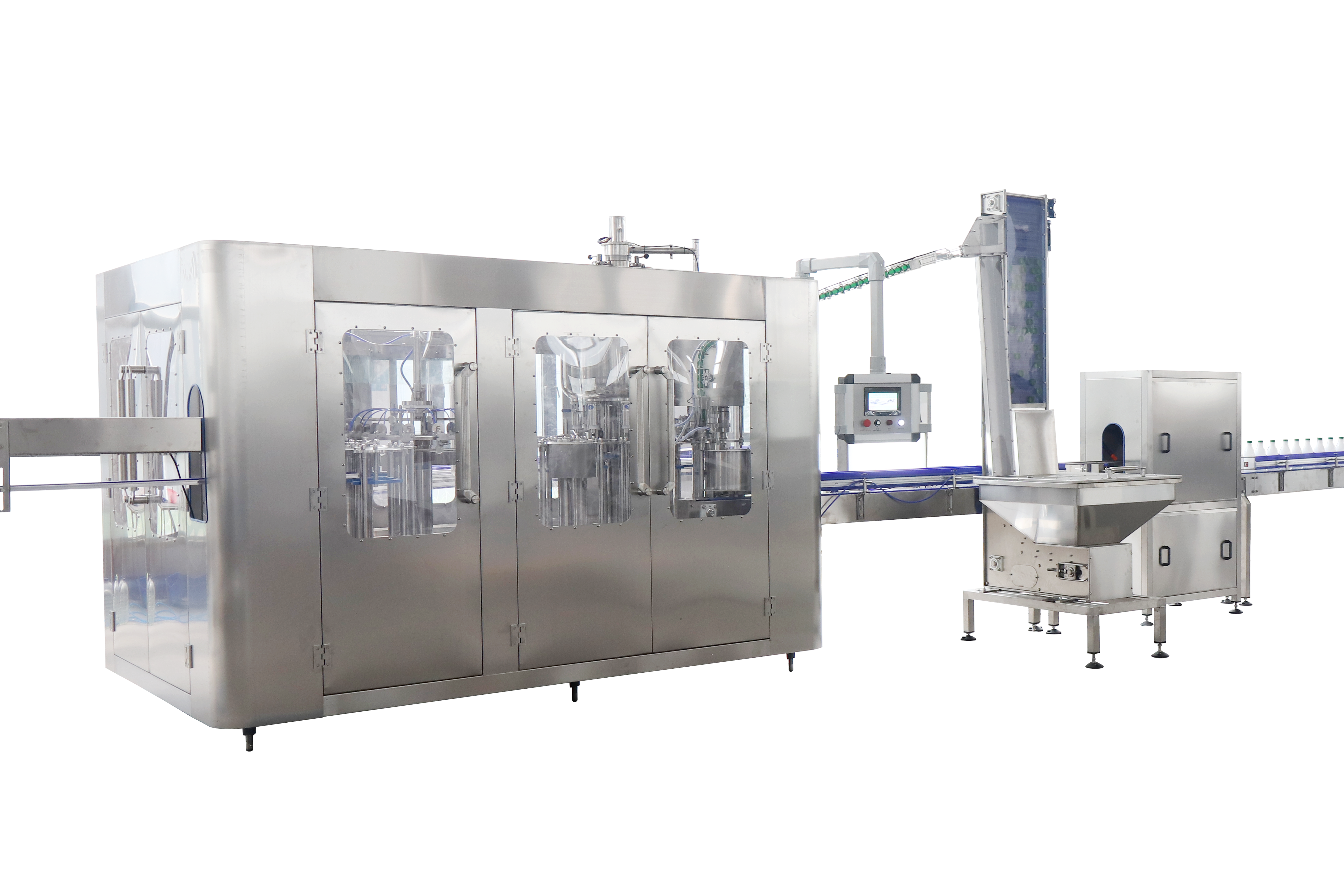

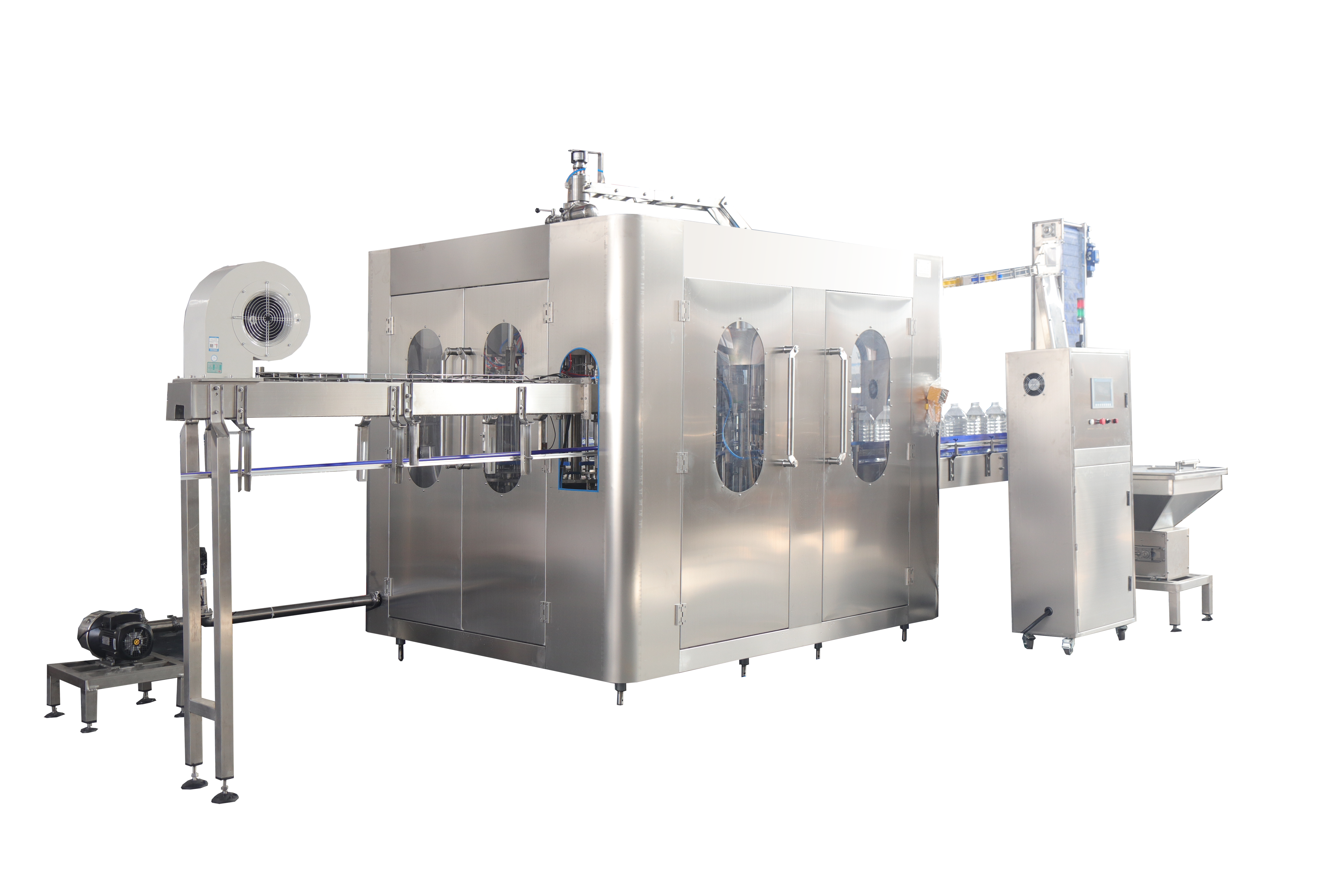

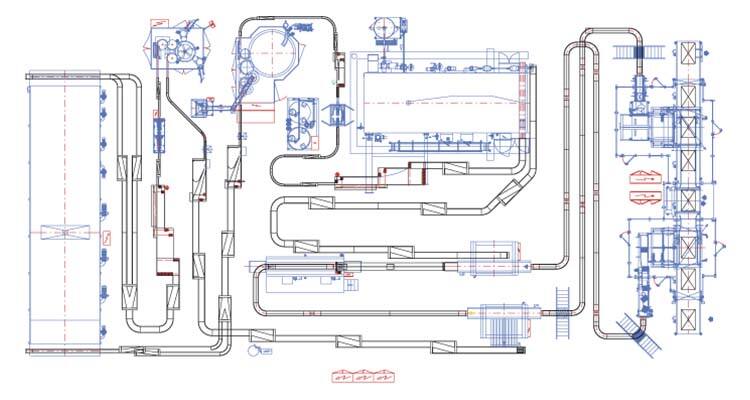

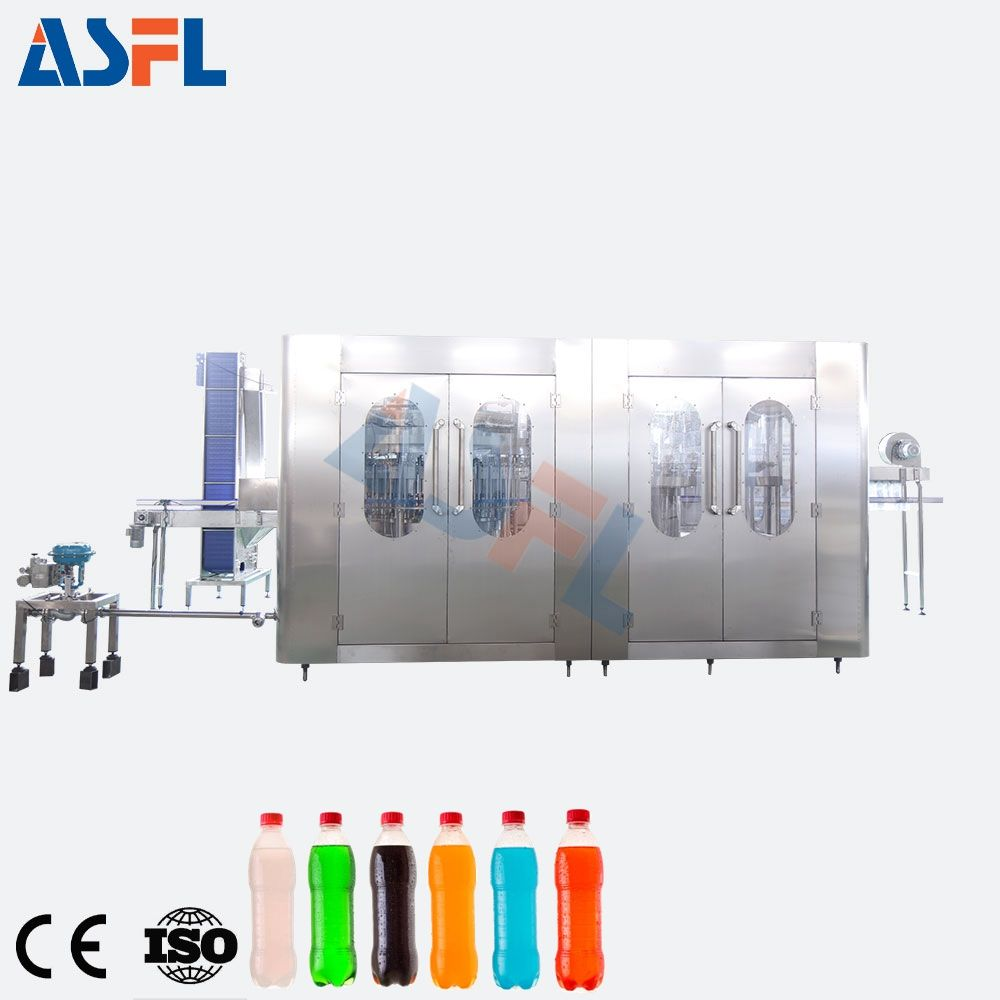

Karbonatlı içecek doldurma makinesi çalışma süreci

Şişe hazırlama temizliği ve dezenfeksiyonu: doldurmadan önce şişeler temizlenir ve dezenfekte edilir, böylece içlerinde fazladan madde veya kirletici maddeler kalmaz. Çoğu durumda, yeni nesil üretim hatları...

DAHA FAZLA GÖR