Máquina de tratamiento de agua: ¿cómo lograr una purificación eficiente del agua con tecnología avanzada?

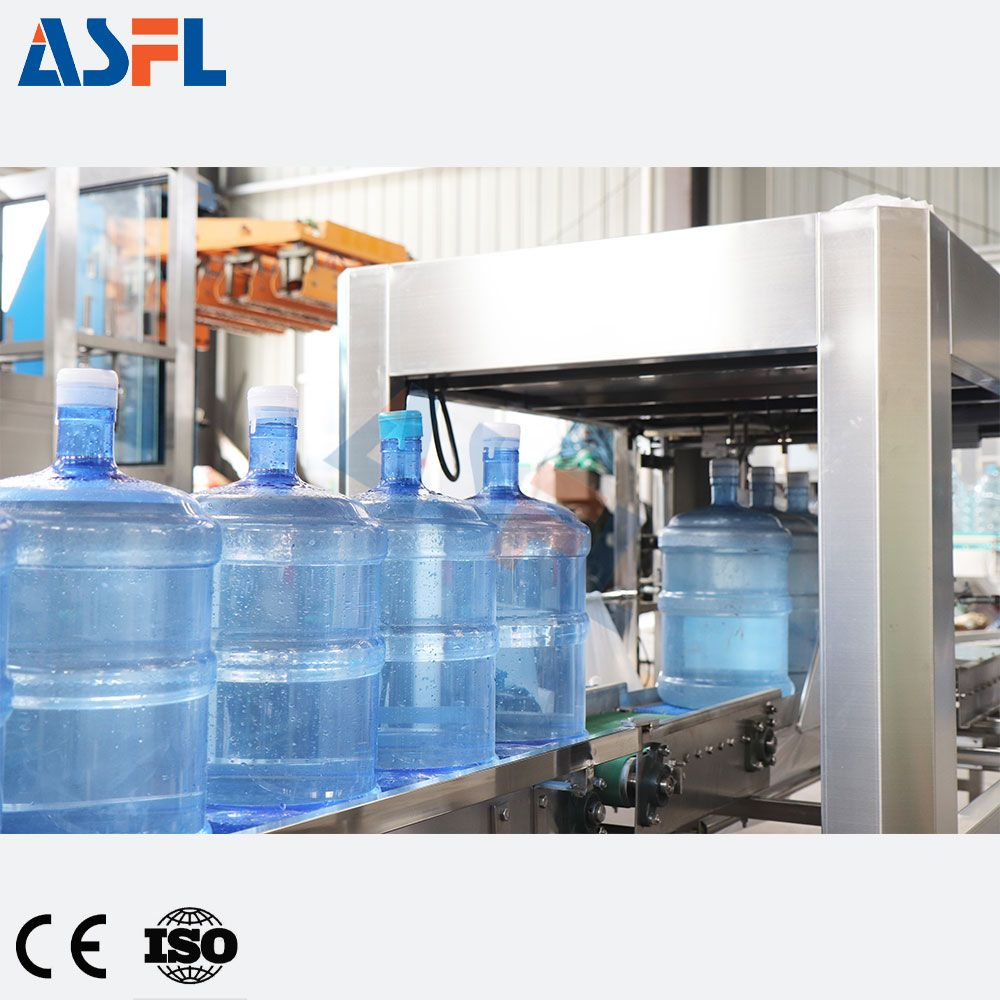

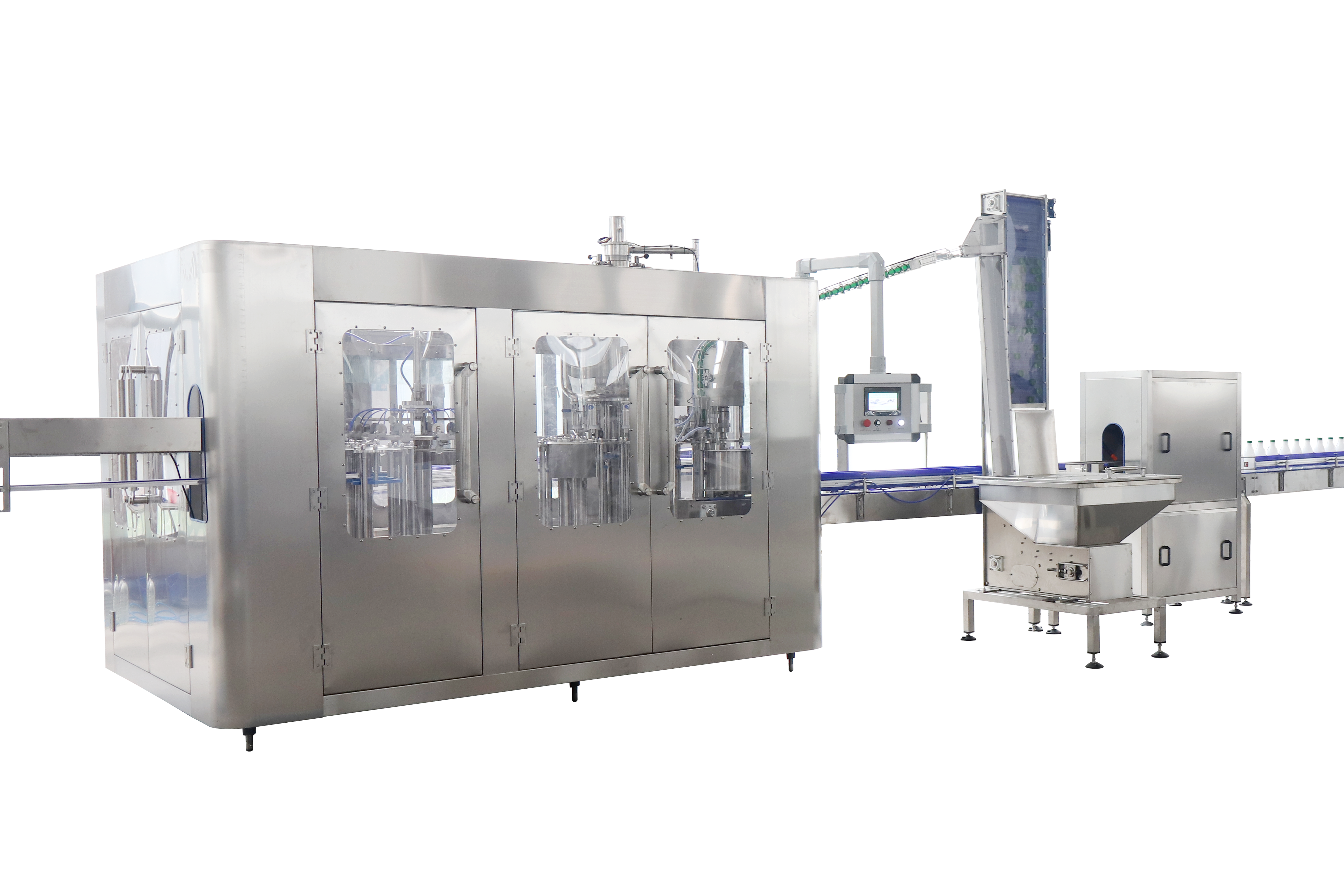

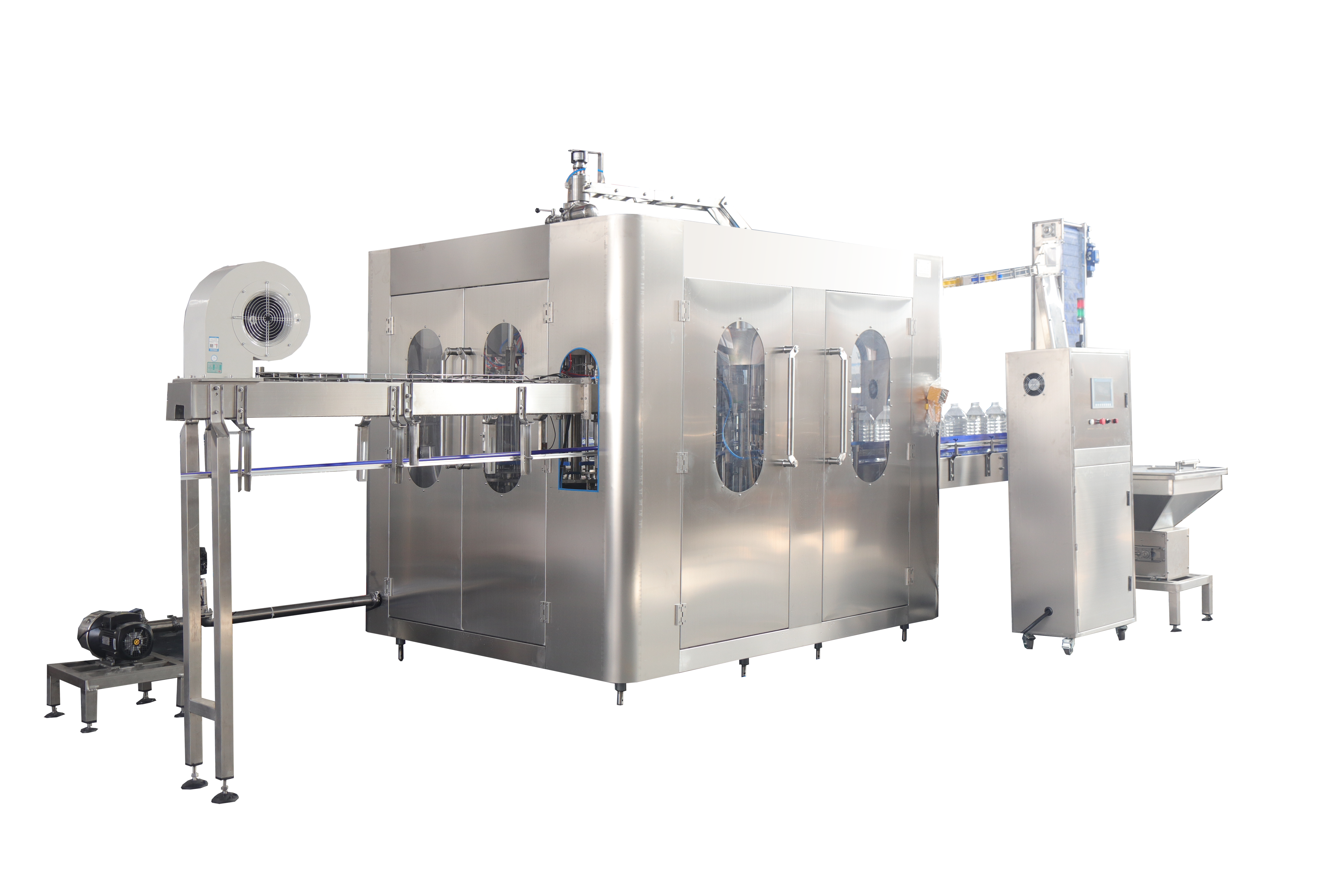

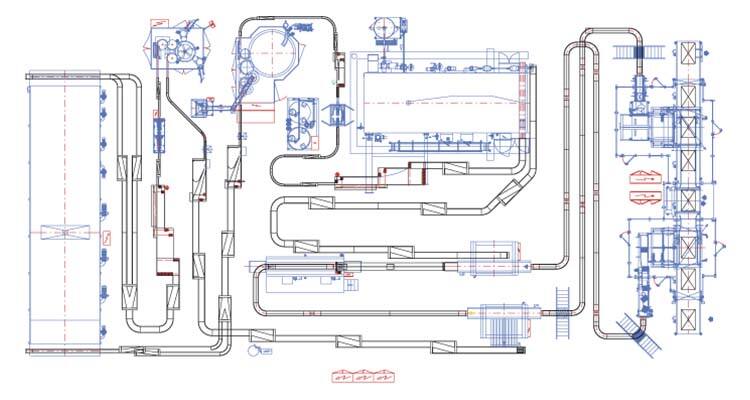

Máquinas de tratamiento de agua: vitales para el agua limpia en el mundo de hoy, el agua limpia y segura es crucial para nuestra supervivencia y bienestar. la contaminación y el agotamiento de los recursos naturales de agua han hecho que la demanda de máquinas de tratamiento de agua eficientes sea mayor...

VER MÁS