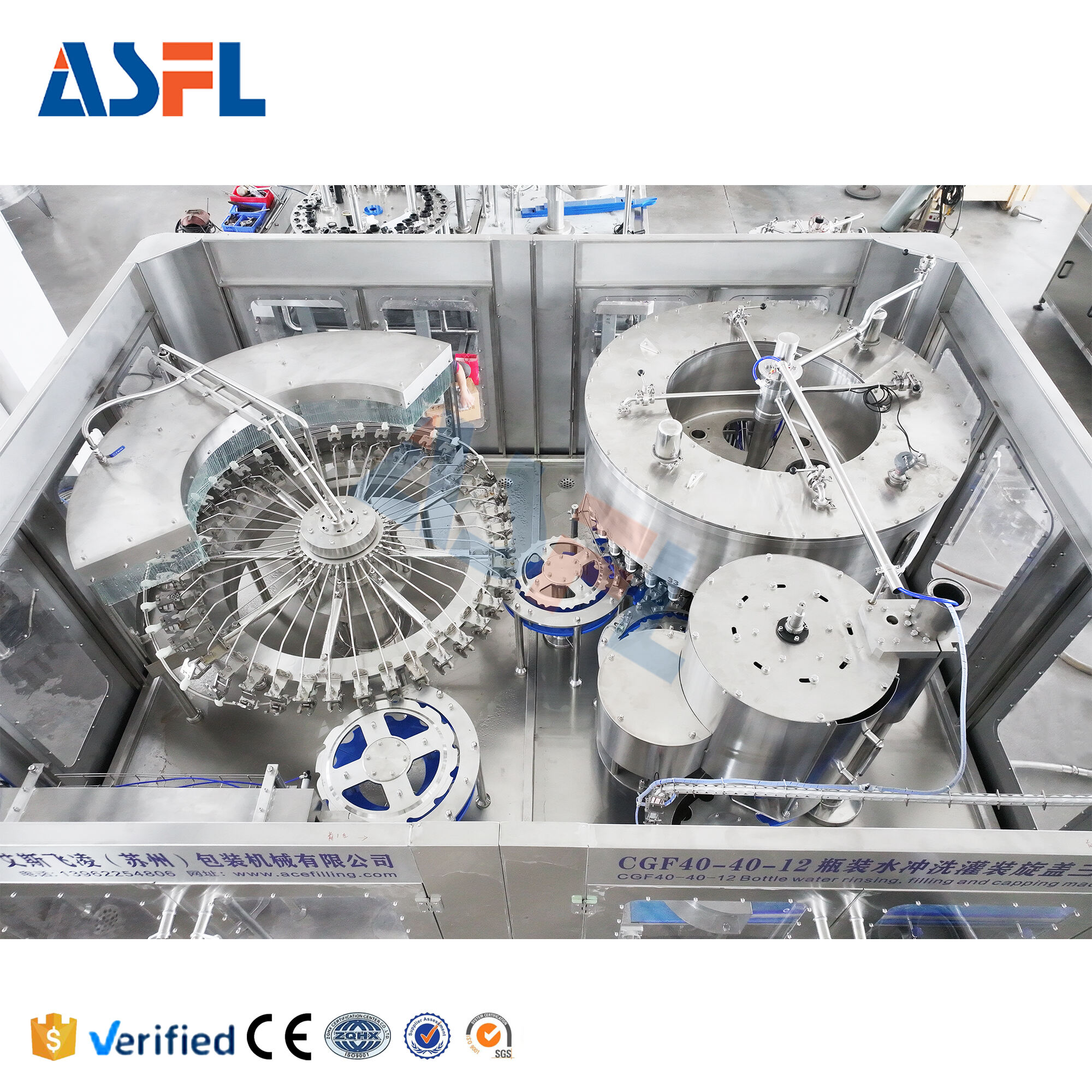

The Large Water Bottle Filling Machine from Ace-Filling is specifically engineered for the efficient packaging of big still water containers, typically ranging from 3 gallons up to 5 gallons (18.9 liters) used in home and office water dispensers. This heavy-duty system is designed to manage the significant weight and size of these containers, often incorporating automated handling systems like conveyor belts with large flights to keep bottles upright and stable. The filling process is typically a gravity-based system for simplicity and reliability, ensuring no over-foaming or spillage. The line usually includes several key stations: an automatic bottle rinser that uses jets of purified water to clean the interior of each bottle, a powerful filling station with multiple nozzles for fast volumetric filling, a capping machine that applies and seals the cap, and finally, an outer sealing station that applies a shrink wrap sleeve for tamper evidence. For a thriving regional water distribution company, this machine is the heart of their operation, enabling them to meet daily demand for fresh, clean drinking water. Given the large volume per container, filling accuracy is critical to avoid significant product loss. For more details on our large water bottle filling systems and their capacities, please contact our team for expert guidance.