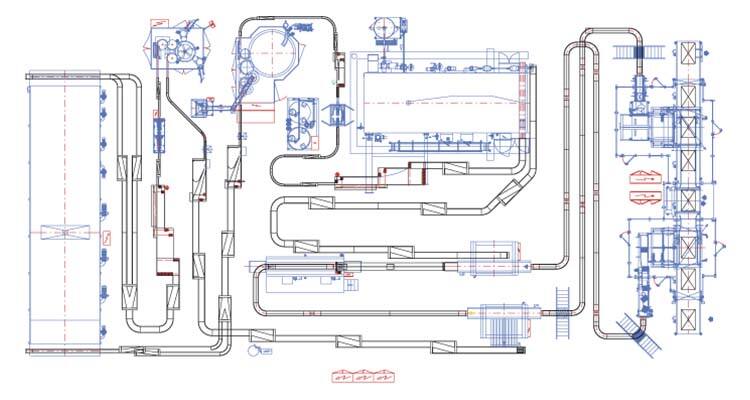

Working Process of Carbonated Beverage Filling Machine

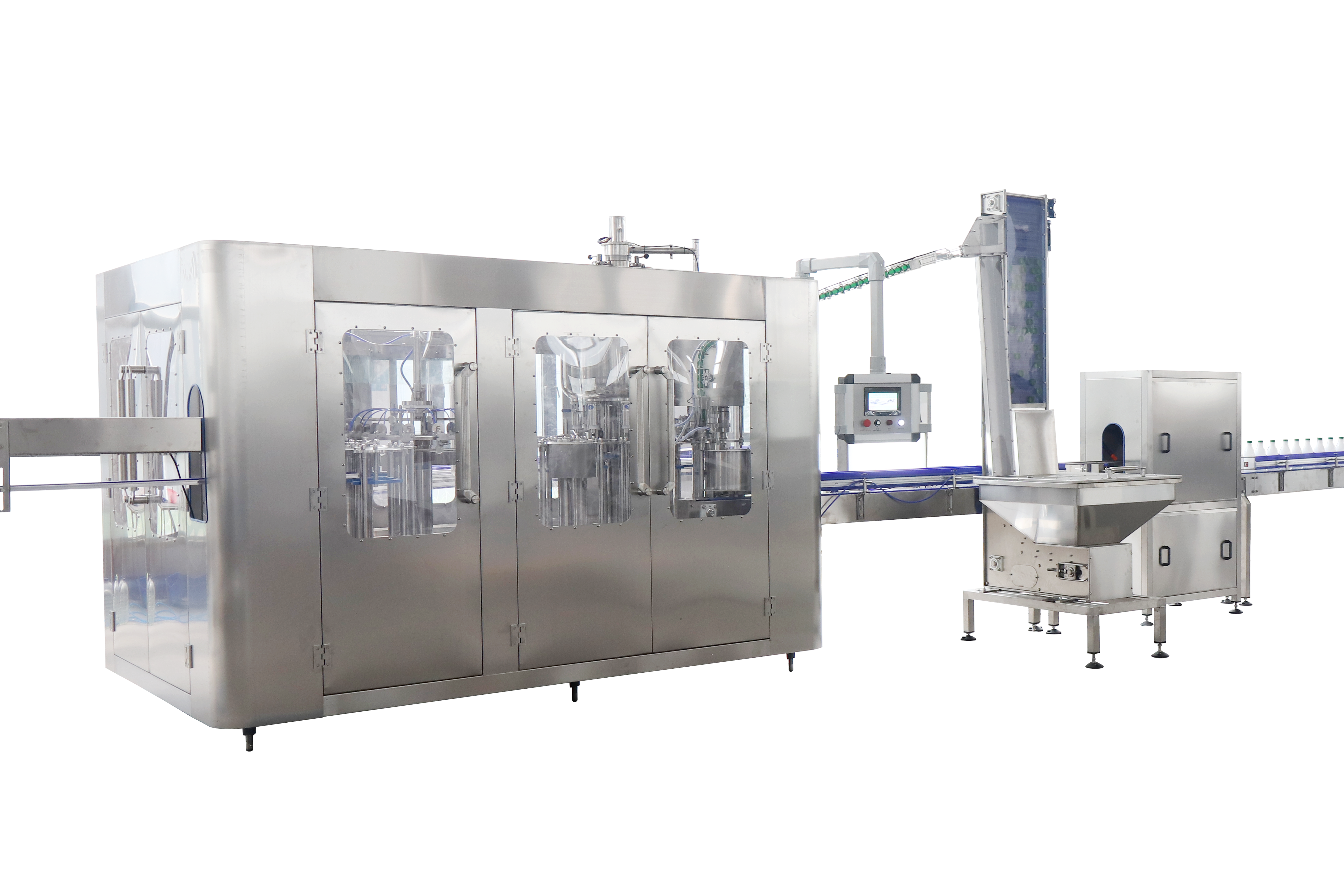

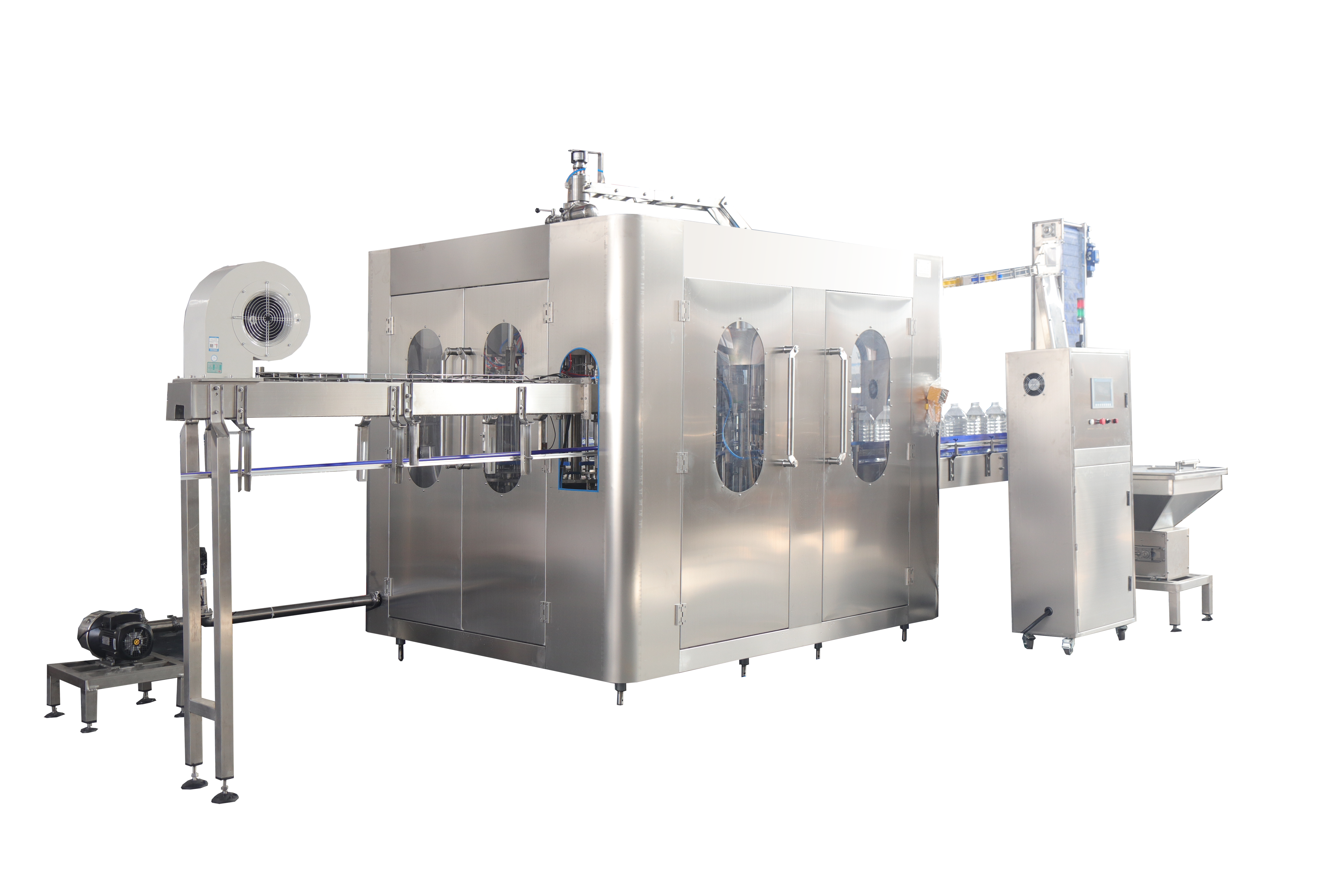

Bottle preparation

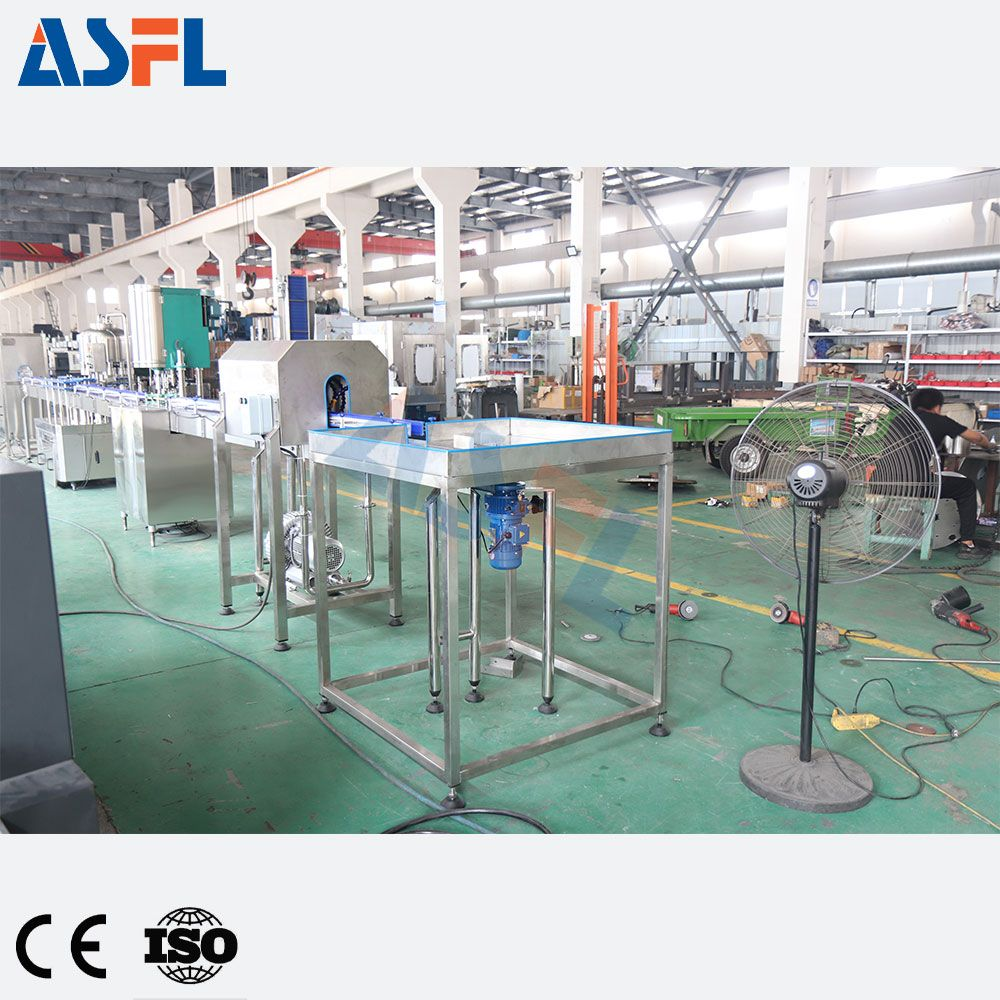

Cleaning and disinfection: Before filling, bottles will be cleaned and disinfected to ensure there are no additional substances or contaminants remaining inside. In most of the cases, the new generation production lines employ the...

View More