Filling Machine: How to Meet the Filling Requirements of Different Liquids?

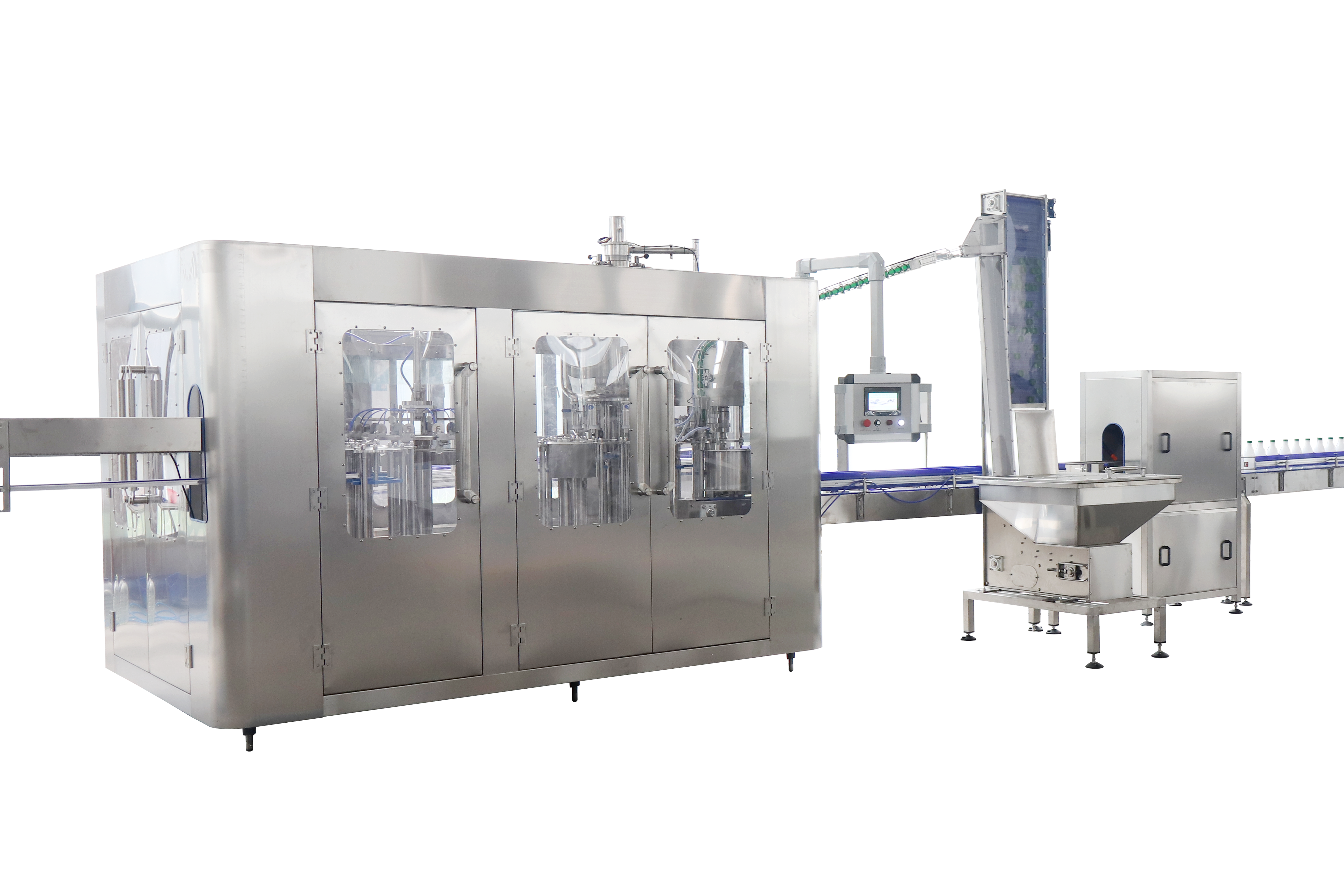

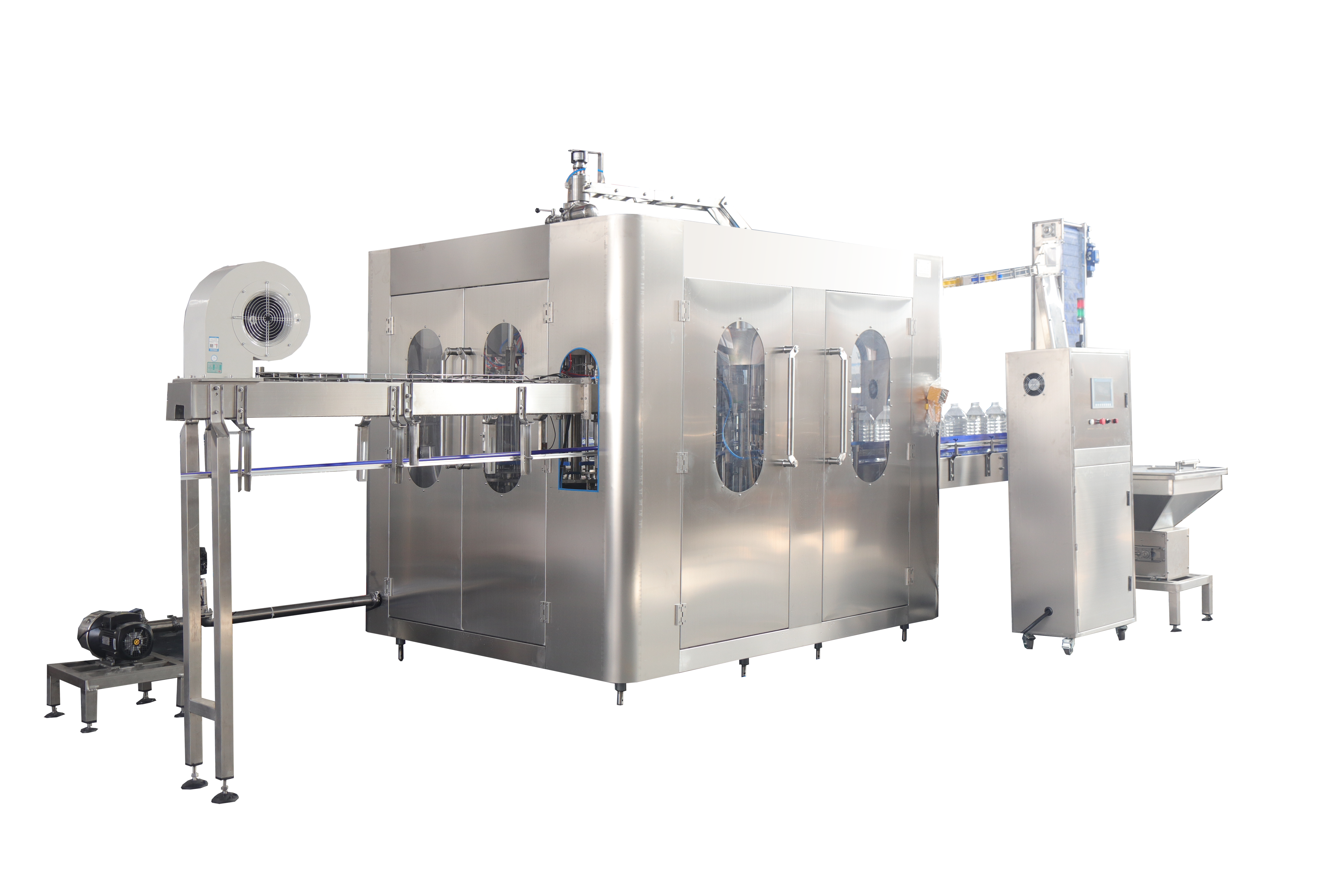

Filling Machines in the Industrial Landscape

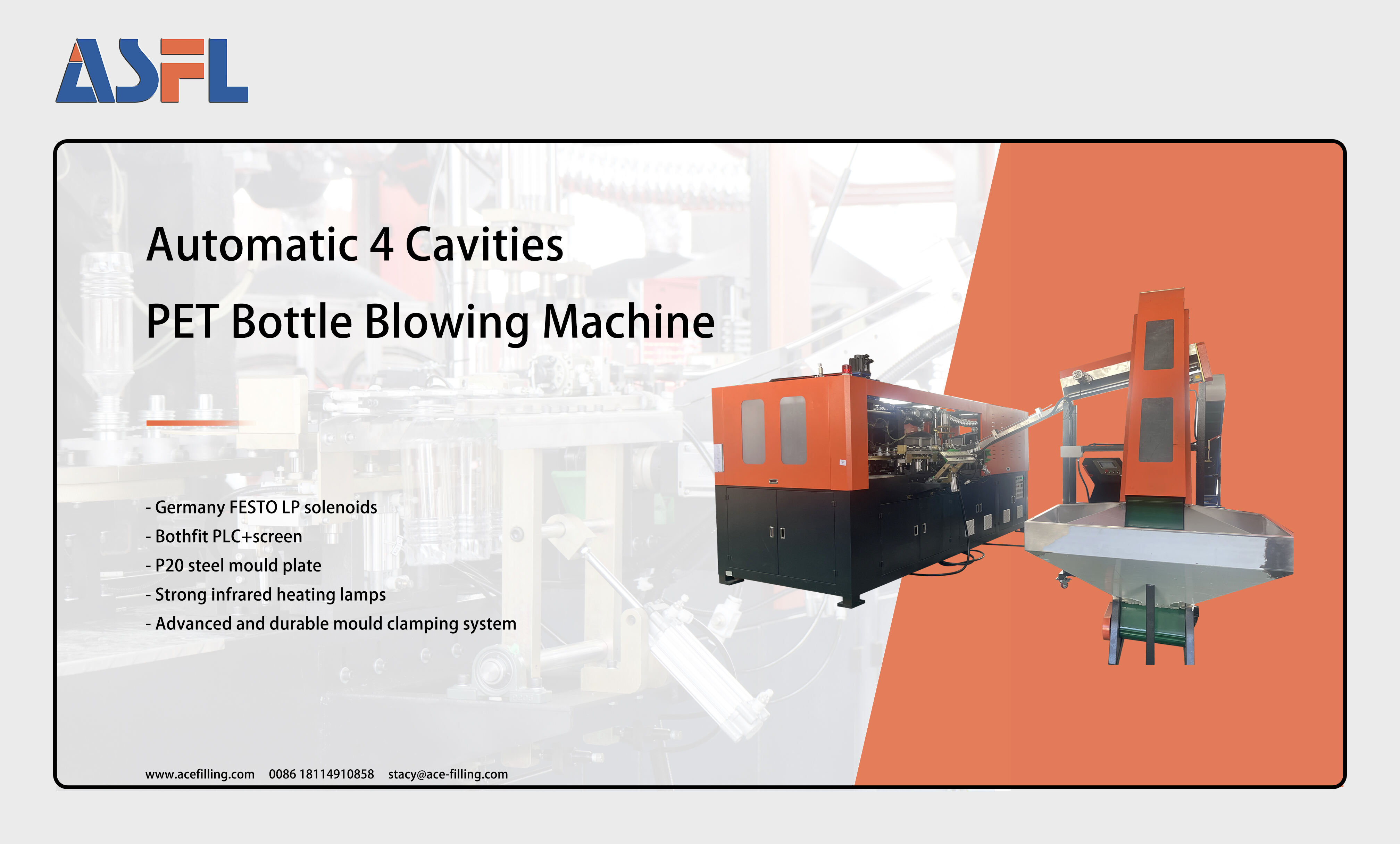

In the modern industrial world, filling machines are crucial. They're the unsung heroes. Ensure efficient packaging of liquids. From beverages to chemicals. Handle a wide range of products. Meeting filli...

View More