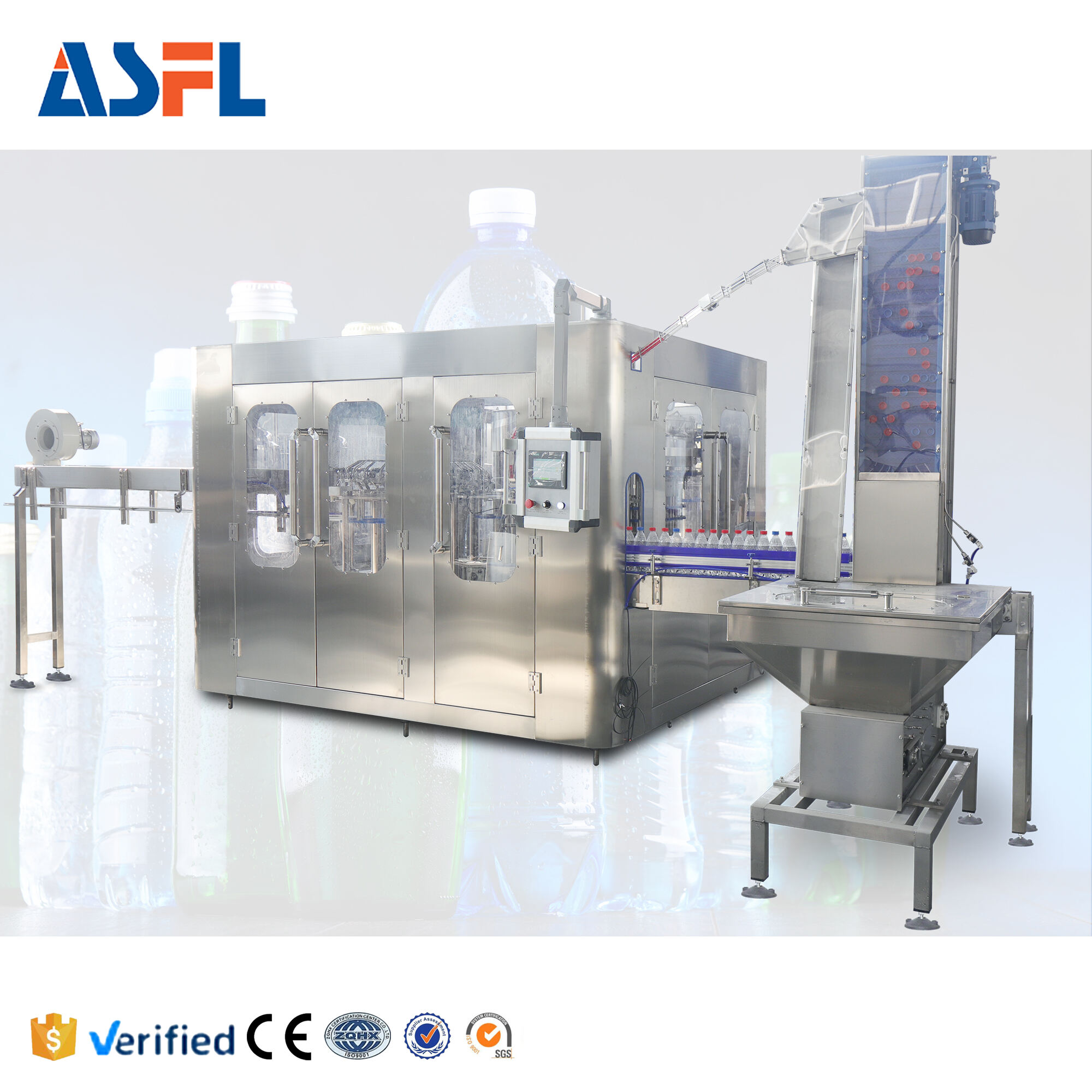

An automatic drink filling machine operates with minimal human intervention, designed to be the core of a continuous production line for maximizing efficiency, consistency, and hygiene. Automation encompasses the entire process from receiving clean, empty containers to discharging filled products. The machine automatically indexes bottles into position, fills them to a precise pre-set volume, and releases them to a conveyor for transport to a capper. This is orchestrated by a central PLC that synchronizes all movements based on inputs from various sensors. Operators control the process through a user-friendly HMI touchscreen, setting parameters and monitoring production data. Automatic fillers are predominantly configured as rotary systems for high efficiency, where containers are filled simultaneously by multiple valves. Key benefits include a dramatic reduction in labor costs, the elimination of human error leading to consistent fill levels and reduced product giveaway, and enhanced hygiene by minimizing human contact with the product. Ace-Filling manufactures a range of automatic drink filling machines designed for reliability and ease of integration with ancillary equipment, providing a seamless and efficient turnkey solution for beverage plants aiming to optimize productivity and ensure uniform product quality.