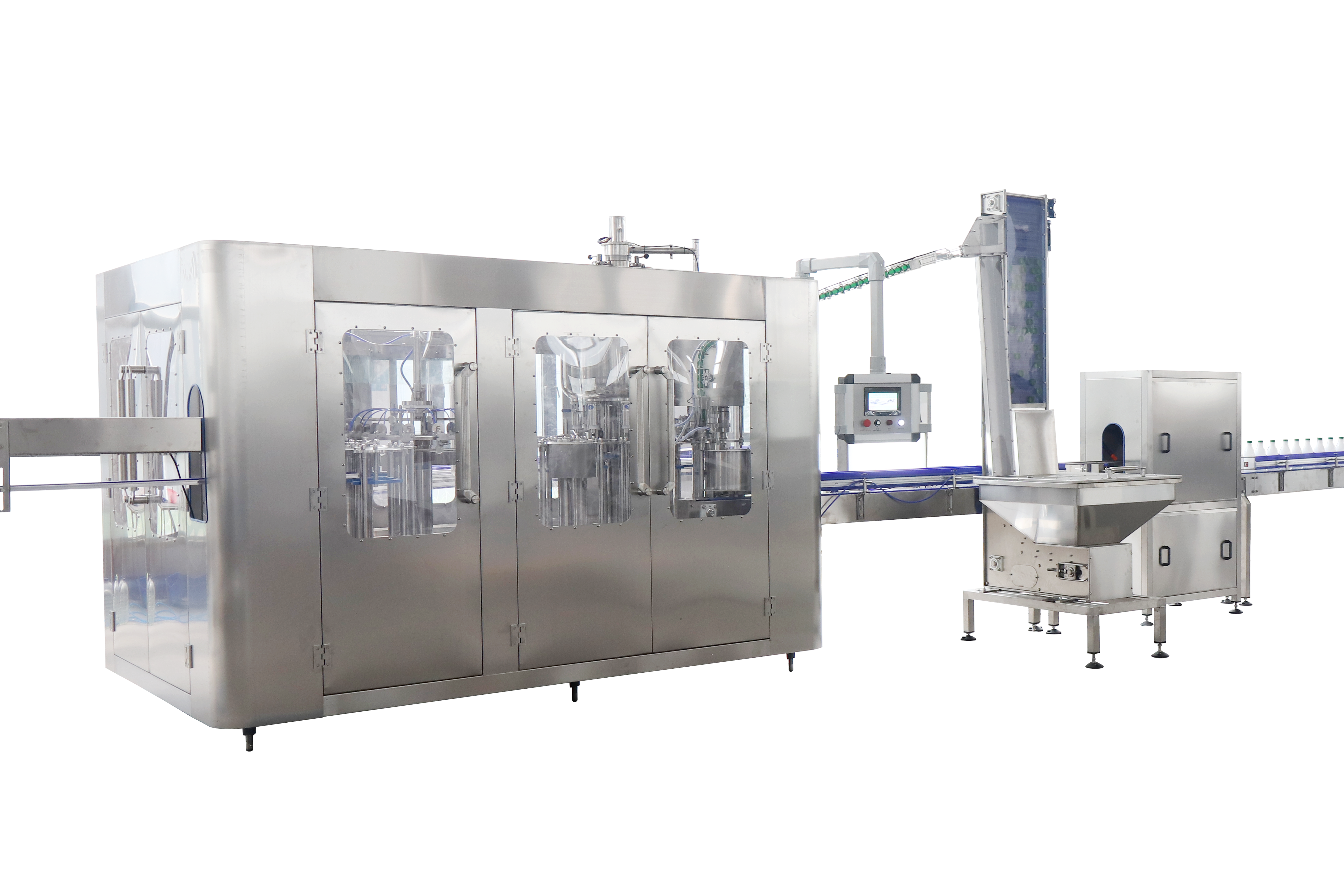

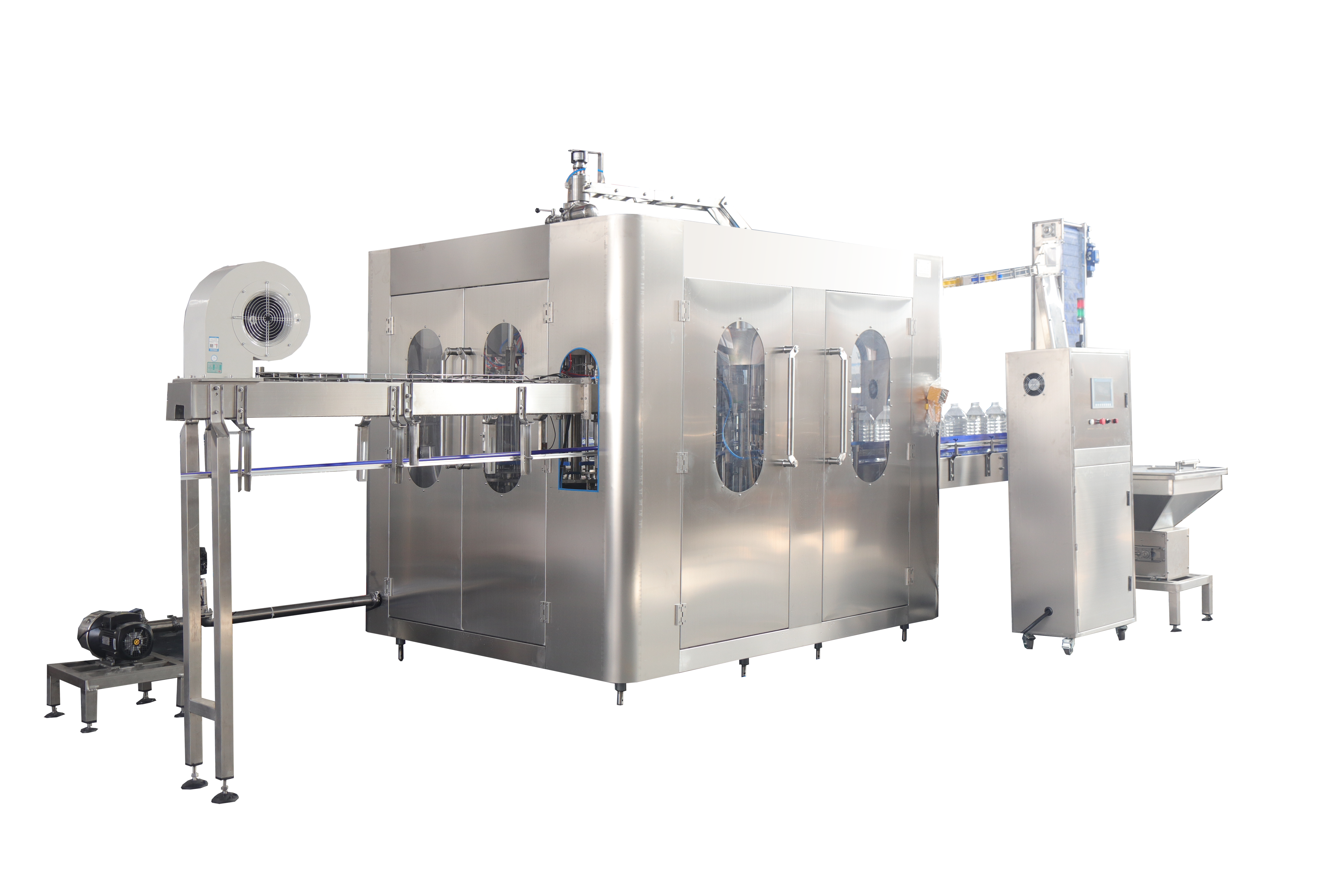

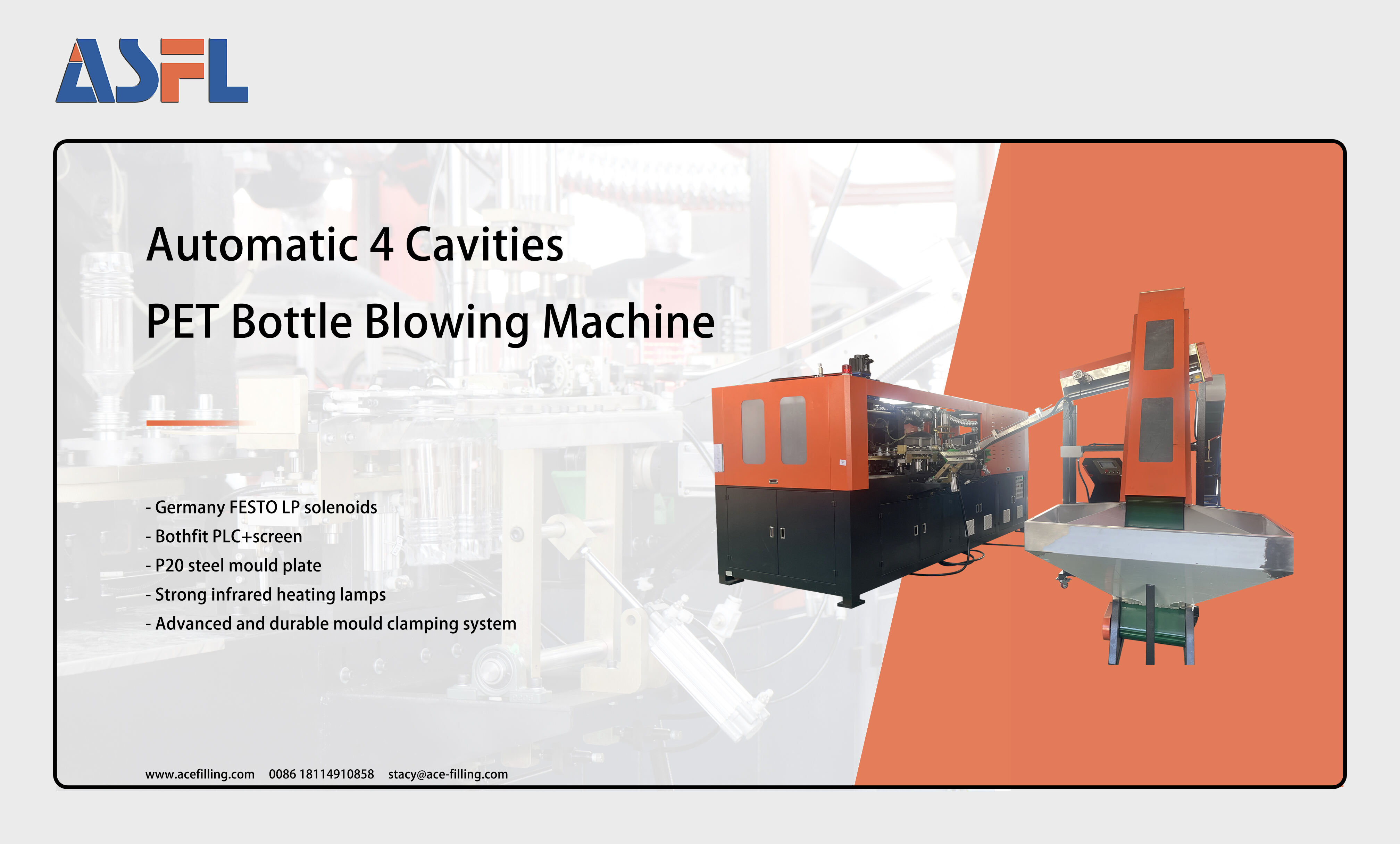

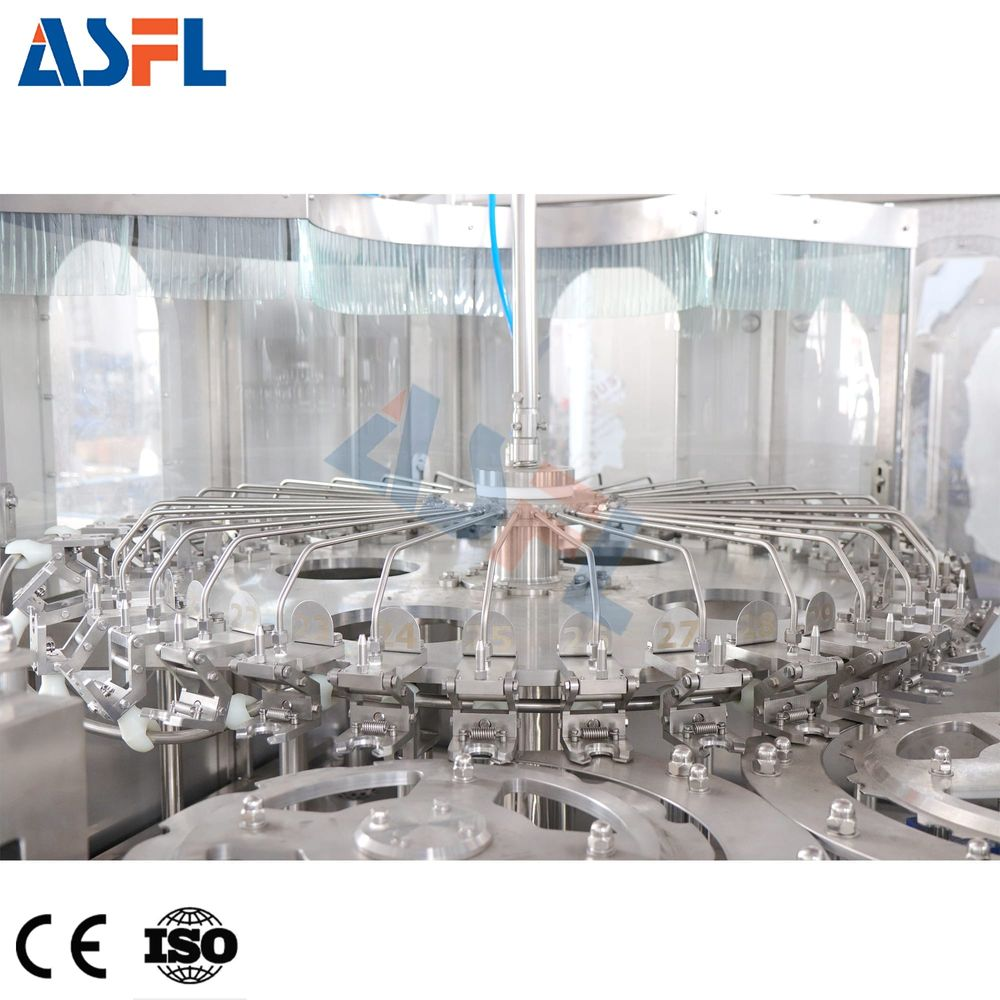

Ace Filling (Suzhou) Packaging Machinery Co., Ltd., a leading enterprise with over 20 years of experience in beverage filling and packaging machinery manufacturing, offers state - of - the - art automatic beer packaging lines. These lines are designed to streamline the entire beer packaging process, from filling to final product output, with high efficiency and precision. The automatic beer packaging lines integrate multiple functions, starting with the beer can or bottle handling section. This section is equipped with advanced conveyors and sorting mechanisms that can handle various sizes and shapes of beer containers smoothly, ensuring a continuous and stable operation. The filling system in the automatic beer packaging line is a core component. It utilizes advanced filling technology, such as isobaric filling for carbonated beers, to ensure accurate volume measurement and minimize foam generation during the filling process. This not only improves the filling accuracy but also helps maintain the quality and taste of the beer. After filling, the capping or sealing part of the automatic beer packaging line plays a crucial role. It uses high - speed and reliable capping machines that can tightly seal different types of caps, such as crown caps for bottles or end caps for cans, ensuring the beer remains fresh and protected from external contaminants. The labeling and coding unit in the automatic beer packaging line is also highly sophisticated. It can apply labels of various materials and sizes accurately and quickly, and at the same time, print batch numbers, expiration dates, and other important information clearly on the containers. Additionally, the automatic beer packaging line includes a quality inspection system. This system uses advanced sensors and imaging technologies to detect any defects in the filled containers, such as leaks, improper filling levels, or damaged labels, ensuring that only high - quality products leave the production line. With a plant area of about 5000㎡ and advanced processing and testing equipment, Ace Filling can ensure the high - quality manufacturing of its automatic beer packaging lines. The company also provides comprehensive services, including process consulting to help customers design the most suitable production process, plant graphic design to optimize the layout of the production site, installation and commissioning to ensure the smooth start - up of the equipment, and technical training to enable customers' staff to operate and maintain the automatic beer packaging lines proficiently. These automatic beer packaging lines from Ace Filling have been well - received by customers in over 50 countries, such as Russia, Kazakhstan, the United States, and others, due to their high efficiency, reliability, and the company's excellent after - sales service, which can meet the diverse needs of breweries worldwide.