Water Treatment Machine: How to Achieve Efficient Water Purification with Advanced Technology?

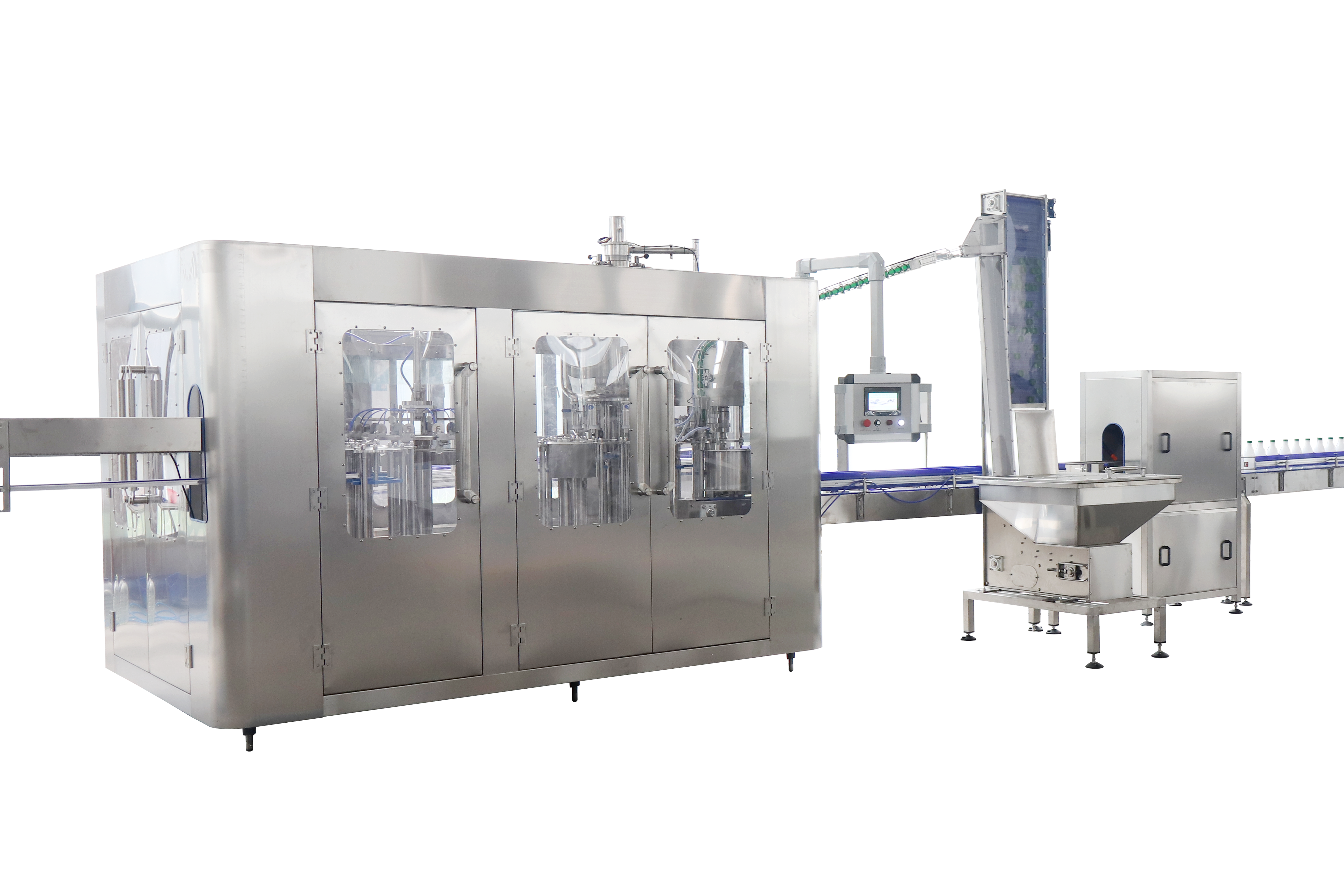

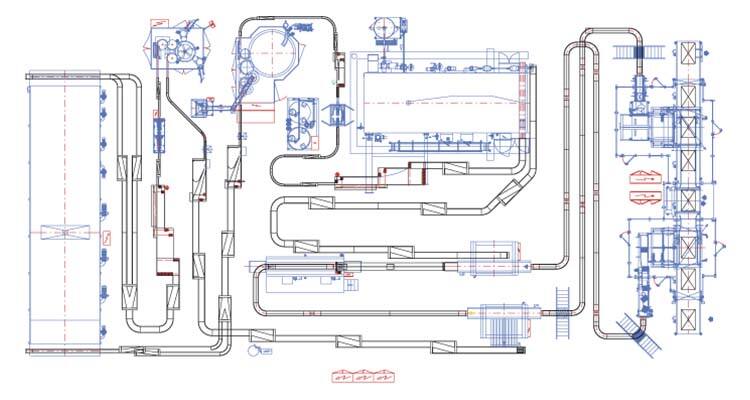

Water Treatment Machines: Vital for Clean Water

In today's world, clean and safe water is crucial for our survival and well-being. Pollution and depletion of natural water resources have made the demand for efficient water treatment machines higher...

View More